Molybdenum crucibles have extensive and critical applications in the ceramic industry, especially in the sintering and melting processes of special ceramics that require high temperatures and clean environments. The following is a detailed analysis of its application in the ceramic industry:

- Which ceramic processes are molybdenum crucibles suitable for?

- High temperature sintered ceramics

Molybdenum crucibles are commonly used in high temperature sintering processes of the following ceramic materials:

Zirconia (ZrO ₂) ceramics

Alumina (Al₂O₃) ceramics

Silicon nitride (Si₃N₄) and silicon carbide (SiC)

Aluminum Nitride (AlN)

Rare earth oxide ceramics (such as Y₂O₃, La₂O₃)

Ceramic Matrix Composites (CMC)

These ceramics are usually sintered at high temperatures (>1600°C), and molybdenum crucibles are ideal sintering containers due to their high melting point (3410°C) and chemical stability.

- Application advantages of molybdenum crucible

- High temperature stability

Molybdenum can work stably up to over 2000°C in vacuum and inert atmosphere, and is suitable for ultra-high temperature sintering or melting operations.

- High purity, avoiding ceramic contamination

molybdenum crucible materials is generally above 99.95%. It will not release impurities or gases at high temperatures like graphite or oxide crucibles, which can ensure the electrical insulation and purity of ceramic products.

- Good thermal conductivity

Molybdenum has high thermal conductivity (about 138 W/m·K), which ensures uniform heating of the ceramic material and helps the uniform growth and densification of the grains.

- High strength, not easy to deform

Even at high temperatures, molybdenum still has good mechanical strength and thermal shock resistance, is not easy to collapse or crack, and is suitable for multiple uses.

- Specific application examples

- Melting of transparent ceramics

For example, **YAG ceramics (yttrium aluminum garnet)** or MgAl ₂ O ₄ spinel ceramics need to be melted and recrystallized in a pollution-free, high-temperature environment, and the molybdenum crucible provides a stable container.

- Sintered nitride and carbide ceramics

The sintering temperature of these materials is extremely high and has strict requirements on the container material. Molybdenum crucible can withstand the sintering temperature of high-hardness ceramics such as silicon nitride and boron carbide.

- Used in vacuum or hydrogen sintering furnace

Molybdenum crucibles are widely used as firing vessels in the mass production of ceramic components (electrical insulation substrates, thermistor chips, microwave ceramics, etc.) in vacuum furnaces or reducing atmospheres (H 2).

======================================================================

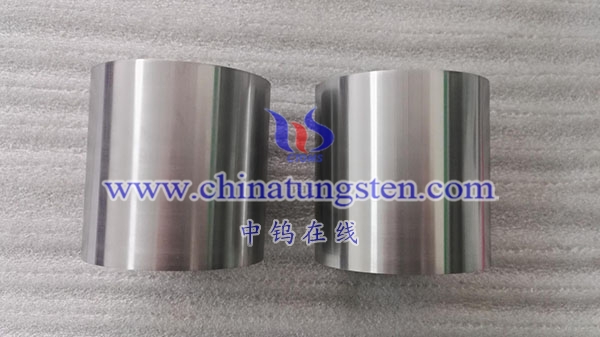

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595