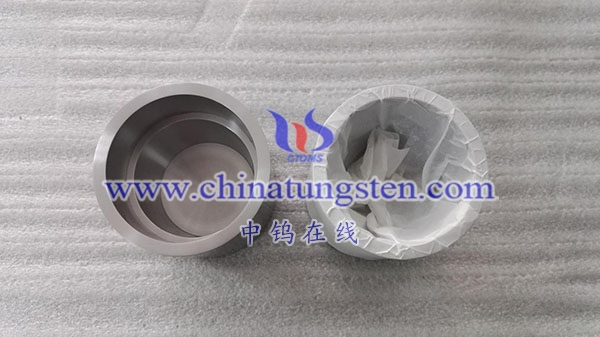

Molybdenum crucible plays a vital role in crystal growth equipment. It is not only a container for high-temperature melt, but also one of the core components for controlling temperature field and crystal quality. In the growth process of sapphire, oxide crystals, nitrides, carbides, rare earth crystals, etc., the structure, performance and processing accuracy of molybdenum crucible will directly affect the stability, uniformity and final product quality of crystal growth.

- The main role of molybdenum crucible in crystal growth

- High temperature melt container

Molybdenum crucible is the direct carrier of molten raw materials (such as alumina, yttrium oxide, aluminum nitride, etc.) during the crystal growth process. It maintains structural stability in a high temperature environment and withstands long-term heating.

Applicable temperature: above 2000°C (vacuum or inert gas environment)

Molten environment: non-polluting, non- reactive (high purity molybdenum material)

- Temperature field controller

Molybdenum has good thermal conductivity. The shape, thickness and relative position of the crucible to the heater will significantly affect the temperature field distribution of the melt, thereby controlling the growth rate, interface shape and defect density of the crystal.

- Thermodynamic equilibrium stabilizer

Molybdenum crucibles can reduce melt fluctuations, inhibit thermal convection instability, and help achieve a smooth growth interface, which is a necessary condition for high-quality crystals (such as low-dislocation sapphire, YAG, LuAG, etc.).

- Physical barriers to growth atmosphere

Molybdenum crucible can effectively isolate the external atmosphere from the melt, prevent atmospheric impurities from entering the crystal, and ensure the purity and structural integrity of the crystal.

- Application Examples in Typical Crystal Growth Equipment

- Czochralski Method

Applicable crystals: sapphire, YAG, Gd ₃ Ga ₅ O ₁₂, etc.

Molybdenum crucible is used to load molten oxide, and cooperates with tungsten heater and reflective screen to form a thermal field system.

Control the temperature gradient to ensure stable seed “pulling”

- Horizontal Directional Solidification (HDS) / Bandpass Method

Applied crystals: Aluminum nitride (AlN), Silicon carbide (SiC)

Molybdenum crucibles provide an inert, high temperature, non-polluting environment

Used with graphite structures in directional temperature control systems

- Bridgman Method

Applied crystals: CdTe, Ga₂O₃, alumina, etc.

The molybdenum crucible holds the raw material and moves slowly along the temperature gradient to achieve crystal solidification.

- Floating Zone

Although crucibles are not used, molybdenum crucibles are still required as high-temperature reaction vessels in some pre-melting charging or impurity purification steps.

- Advantages of Molybdenum Crucible in Crystal Growth

Extremely high melting point (3410°C), resistant to extreme temperature conditions

High purity (>99.95%), ensuring that the crystal is not contaminated by impurities

Excellent thermal conductivity, easy to build a stable temperature field

Good mechanical strength and thermal shock resistance, no deformation during long-term operation at high temperature

Adapt to vacuum/inert atmosphere, no oxidation or volatilization

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595