In alloy material research, molybdenum crucible is a very critical experimental tool, especially suitable for high-temperature smelting, controlled purity preparation, trace alloy element addition and thermal property testing. Its excellent high-temperature performance and chemical stability make it an irreplaceable experimental auxiliary equipment for studying refractory alloys, active metal systems, rare earth metal alloys, and ultra-high purity alloy materials.

- The key role of molybdenum crucible in alloy material research

- High temperature alloy melting container

Molybdenum crucibles can withstand temperatures above 2000°C and are suitable for the preparation of:

High melting point alloys (such as W-Ni-Fe, Ta-based, Re-based systems)

Refractory rare earth alloys (such as Nd-Fe-B, Gd magnetic materials)

Special alloys for aviation/nuclear applications (such as Ti-Al, U-Mo, etc.)

Ensure that the melt is uniform, the reaction is complete and there is no pollution.

- Trace alloying element addition and impurity control test

High purity molybdenum itself does not release impurities and does not react with most alloying elements:

Suitable for trace doping (such as adding micro-alloying elements such as B, Zr, Nb, etc.)

It can ensure that the doping elements are not adsorbed or reacted by the crucible wall

Ensure experimental repeatability and element content control accuracy

- Phase diagram determination and thermal analysis experiments

In equipment such as DSC (Differential Scanning Calorimetry), TG-DTA, etc., molybdenum crucibles can be used for:

Alloy melting point determination

Phase change thermal analysis

Solid-liquid equilibrium curve drawing

Accurately record thermal effects without interfering with the thermal response of the alloy system.

- Study on alloy behavior under controlled atmosphere conditions

Molybdenum crucible is suitable for:

Vacuum system (high vacuum sintering, electron beam melting)

Inert atmosphere (argon, helium protection)

The following stable working conditions can be used for research:

Alloy oxidation and volatilization behavior

Gas dissolution/precipitation behavior (such as hydrogenation-dehydrogenation process)

Intermetallic Stability

- Overview of experimental advantages

| Advantages | illustrate |

| High temperature adaptability | High melting point, not easy to deform or melt |

| High purity guarantee | Does not introduce impurity elements, especially suitable for analytical experiments |

| Strong inertness and compatibility | Unreactive with most metals and alloy systems |

| Strong reusability | proper maintenance, which is economical |

| Support special atmosphere | Adapt to operation in vacuum, argon, helium and other environments |

- Examples of Typical Experimental Scenarios

| field of study | Application Scenario |

| High temperature alloy research and development | Synthesize Ni-based, Mo-based, and Re-based alloys and study microstructure evolution |

| Magnetic alloy preparation | Melting rare earth magnetic alloys such as NdFeB and SmCo |

| Intermetallic compound formation mechanism | Study the formation and stability of Al₃Ti, NiAl, FeAl, etc. |

| Thermophysical properties measurements | Determination of melting point, specific heat, enthalpy change, etc. |

| Aerospace alloy simulation | Simulate material behavior under extreme conditions (high temperature/vacuum/inertness) |

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

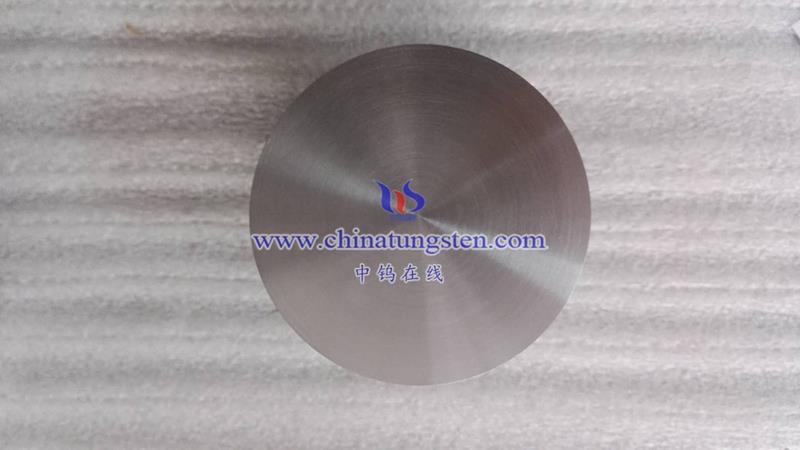

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595