Molybdenum crucibles can be used for melting experiments of some inorganic salts, but the following specific conditions must be met because molybdenum is chemically sensitive to some inorganic salt systems. The following is a detailed description:

- Analysis of the applicability of molybdenum crucible in inorganic salt melting experiments

Applicable conditions:

The experimental atmosphere is inert or vacuum

Molybdenum is easily oxidized at high temperatures, and molten salt experiments must be carried out in an argon or helium protective atmosphere or under high vacuum conditions.

Molten salt system is chemically compatible with molybdenum

Molybdenum is suitable for salts that do not contain strongly oxidizing components, such as:

Chloride salts (such as NaCl, KCl, LiCl- KCl eutectic system)

Fluoride salts (such as LiF-BeF₂)

Some nitrates can also be used in short-term experiments at low temperatures, but they need to be protected from oxygen intrusion.

Reasonable temperature control

Most inorganic salts have low melting points (200–1000°C), far below the temperature limit of molybdenum. Molybdenum provides excellent high temperature stability.

Taboo scenes:

Inorganic salts containing strong oxidizing ions (such as NO₃⁻, SO₄²⁻, CrO₄²⁻, etc.) will oxidize molybdenum at high temperatures;

Containing hydrates or easily hydrolyzed salts, the heating process may release water or acid gas, corroding the crucible;

When operated in air, molybdenum is easily oxidized to form MoO₃ at temperatures above 600°C, causing rapid damage.

- Typical applications of molybdenum crucibles in inorganic salt experiments

| Application | Example |

| Molten Salt Electrolysis Research | Preparation of metallic aluminum, titanium, and rare earth in LiCl- KCl or NaCl- CaCl₂ |

| Molten salt thermal properties test | Determination of thermal properties such as thermal conductivity, specific heat, density, etc. |

| High temperature corrosion test | Salt corrosion resistance test of alloy samples using inert salt system |

| Research on molten salt heat storage materials | Study on heat storage efficiency and thermal cycle stability (such as NaNO₃ – KNO₃) |

| Experiment with molten salt fuel for nuclear energy | Melting and thermal property analysis of LiF -BeF₂ – UF₄ system |

- Precautions for use

Interior coating treatment recommendations

To avoid trace reactions, boron nitride (BN), aluminum oxide (Al₂O₃) or graphite coating can be sprayed on the inner wall of the molybdenum crucible to improve salt resistance.

Heating rate control

Avoid local overheating, which may cause thermal stress cracking or surface oxidation of the crucible.

Cleaning and reuse

The molten salt residue must be completely removed, otherwise it may cause cross contamination in subsequent experiments;

It is recommended to use mechanical slag removal + low temperature burning + vacuum drying.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

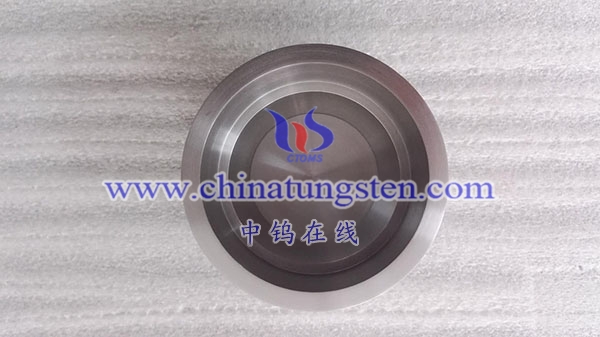

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595