Molybdenum crucible should be selected according to the type of pollution. The following are common cleaning methods and their applicable scenarios:

- Mechanical cleaning

Applicable scenarios: particles, oxides or metal residues attached to the surface.

method:

Physical scrubbing: Use a soft-bristle brush or a nylon brush with deionized water or an organic solvent (such as ethanol) for scrubbing.

Ultrasonic cleaning: Place the crucible in an ultrasonic cleaner and use ultrasonic vibrations to remove tiny particles.

Note: Avoid using hard brushes or steel wool to avoid scratching the inner wall of the crucible.

- Chemical Cleaning

Applicable scenarios: metal oxides, salts or organic pollution.

method:

Pickling: Use dilute hydrochloric acid (HCl) or nitric acid (HNO₃) solution to remove metal oxides.

Alkaline washing: Use sodium hydroxide (NaOH) or potassium hydroxide (KOH) solution to remove organic matter.

Composite cleaning agent: For complex pollution, special cleaning agents containing fluoride or complexing agent can be selected.

Note:

After cleaning, rinse thoroughly with deionized water to avoid corrosion of the crucible by residual acid and alkali.

The concentration of acid and alkali solutions and the immersion time need to be adjusted according to the degree of contamination to avoid excessive corrosion.

- High temperature burning cleaning

Applicable scenarios: organic pollution or residues that are difficult to remove.

method:

The crucible is placed in a high temperature furnace and heated to 800°C-1200°C in an air or oxygen atmosphere to completely oxidize and decompose the organic matter.

Note:

The burning temperature should be selected according to the crucible material and contamination type to avoid deformation or oxidation of the crucible due to excessive temperature.

After burning, it needs to be cooled slowly to prevent cracking caused by thermal stress.

- Plasma cleaning

Applicable scenarios: high precision requirements or micron-level pollution.

method:

Use plasma (such as oxygen or argon plasma) to bombard the crucible surface to remove organic matter and tiny particles.

Note:

Plasma cleaning equipment is relatively expensive and is only suitable for laboratories or high-end manufacturing scenarios.

- Special cleaning methods

Electrolytic polishing: Removes tiny surface defects and contaminants through electrolysis, suitable for high-precision requirements.

Laser cleaning: Uses a laser beam to remove surface contamination, suitable for local cleaning or complex structures.

- Post-cleaning treatment

Drying: After cleaning, blow dry with nitrogen or dry air, or place in an oven to dry.

Inspection: Use a microscope or roughness tester to check the cleaning effect and ensure that there is no residue on the surface.

- Summary of Precautions

Avoid scratches: Use soft tools when cleaning mechanically.

Control acid and alkali concentration: Chemical cleaning requires strict control of solution concentration and cleaning time.

Prevent secondary contamination: Rinse thoroughly and dry after cleaning to avoid residual moisture or impurities.

High temperature burning protection: During burning, the temperature needs to be raised and lowered slowly to prevent thermal stress damage.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

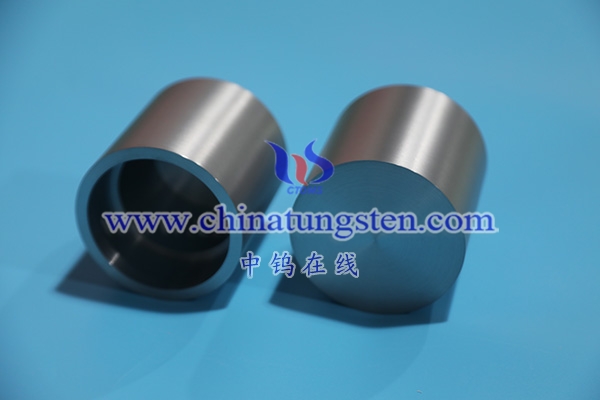

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595