Molybdenum crucibles during use are usually related to factors such as high temperature environment, chemical reaction, and mechanical impact. The following are several common damage modes and causes of molybdenum crucibles:

- Oxidative damage

Cause of damage: Molybdenum easily reacts with oxygen in the air at high temperatures to form molybdenum trioxide (MoO₃). Especially when the temperature exceeds 600°C, the oxidation rate accelerates. After the oxide layer is formed, it will not only make the surface brittle and lose strength, but also make the molybdenum crucible fragile.

molybdenum crucibles in air or oxygen-containing atmosphere, especially when heated directly, the crucible surface is easily oxidized. The oxide layer will weaken the heat resistance of molybdenum and eventually cause the crucible to crack.

- Thermal cracks

Cause of damage: Due to the thermal expansion characteristics of molybdenum, internal stress will be generated when the temperature changes sharply. If the molybdenum crucible is directly placed in a high-temperature environment in a cold state, or suddenly contacts a cold object at high temperature, it will cause thermal stress concentration and thus cracks.

Common situations: Thermal cracks may occur when the temperature rises or cools rapidly, or when there is local overheating on the crucible surface.

- Chemical corrosion

Cause of damage: Molybdenum is very susceptible to corrosion in certain chemical environments, especially acidic, oxidizing or halogen-containing substances. When it comes into contact with strong acids (such as nitric acid, sulfuric acid) and halogen compounds (such as chlorine and fluorine), molybdenum will undergo chemical reactions, resulting in surface damage or consumption.

Common situations: If the molybdenum crucible is used for molten metal or certain chemicals, these substances may react with the molybdenum and cause surface corrosion or erosion.

- Mechanical damage

Cause of damage: Due to the high hardness of molybdenum crucibles, they usually need to be formed by mechanical processing, but external impact, collision or scratches can cause damage or cracking of the crucible surface. Especially during transportation, some improper operations may cause the crucible to be hit or fall, resulting in cracks or ruptures.

Common situations: improper handling or collision of the crucible, use of excessively worn tools.

- Molten salt corrosion

Cause of damage: When the molybdenum crucible is subjected to high-temperature molten salt experiments, the molten salt may penetrate the molybdenum surface, causing local corrosion or fatigue cracking. Certain metal melts (such as aluminum, copper, etc.) may also cause surface degradation when in contact with molybdenum.

Common situations: When using molybdenum crucibles for high-temperature experiments such as molten salt, metal smelting, and crystal growth, if the molten salt composition is unstable or there are too many impurities, it is easy to accelerate the damage of the crucible.

- Surface embrittlement

Cause of damage: At high temperatures, the surface of molybdenum will gradually be oxidized, causing the surface to become brittle. When cooled or the temperature changes greatly, cracks will easily appear in the brittle area of the surface, and even cause rupture.

the molybdenum crucible tends to become brittle, especially when proper protective measures (such as inert atmosphere heating, coating protection, etc.) are not taken.

- Electrical corrosion

Cause of damage: If the crucible is exposed to an environment where electric current flows for a long time, the molybdenum may be affected by electrical corrosion, especially in an environment of electrochemical reaction, resulting in uneven corrosion or consumption of the molybdenum surface.

molybdenum crucibles as electrodes in certain experiments, corrosion or surface deterioration may occur due to the passage of current through the crucible.

How to avoid damage to molybdenum crucible:

Use protective atmosphere: Try to avoid heating in air, use vacuum or **inert gas (such as argon) **protection.

Heat and cool slowly: Avoid rapid changes during heating and cooling to ensure that the temperature changes smoothly and prevent thermal stress.

Regular inspection: Check the surface of the molybdenum crucible before and after each use to check whether there are cracks, damage or oxide layer.

Avoid chemical reactions: When using molybdenum crucibles, avoid contact with strong acids, strong oxidants or halogen-containing substances.

Appropriate coating protection: Boron nitride, graphite and other coatings can be selected to improve the corrosion resistance and reduce wear of the molybdenum crucible.

Handle with care: Avoid impact or collision, use special tools and protective equipment to protect the crucible.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

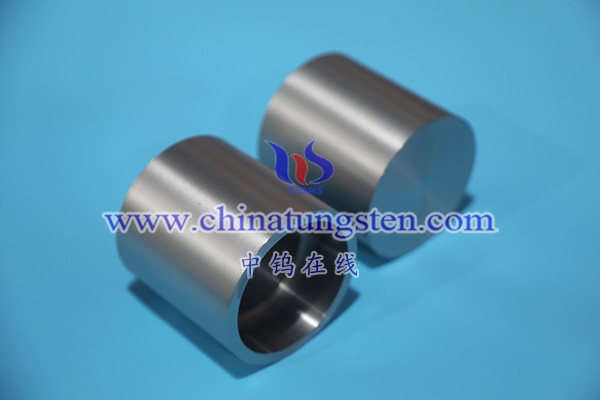

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595