Molybdenum crucibles must focus on preventing oxidation, contamination and mechanical damage. The following are specific precautions:

- Environmental Control

Anti-oxidation

Humidity requirement: The storage environment humidity must be lower than 50% to prevent the molybdenum surface from absorbing moisture and oxidizing to form MoO₃ (molybdenum oxide).

Gas environment: It is recommended to fill with high-purity nitrogen (purity ≥ 99.999%) or argon to form an inert gas protective layer.

Sealing measures: Use vacuum packaging or sealed containers to reduce contact with oxygen.

Anti-pollution

Cleanliness: The storage area must meet ISO 8 (10,000) or higher cleanliness standards to prevent dust, metal particles and other impurities from adhering.

Anti-corrosion: Keep away from corrosive substances such as acid, alkali, salt, etc. to prevent the crucible surface from being corroded.

- Packaging and stacking

Packaging Materials

The inner layer uses polyethylene (PE) or polytetrafluoroethylene (PTFE) film, and the outer layer uses an anti-static aluminum foil bag to prevent static electricity from absorbing dust.

A desiccant (such as silica gel) can be placed in the package to absorb residual moisture.

Stacking method

Independent storage: Crucibles should be separated by soft materials (such as polyurethane foam) to avoid collision.

Fixed support: Use wooden or plastic trays to prevent the crucible from deforming due to stacking pressure.

Maximum number of stacking layers: no more than 3 layers, and the weight of a single layer does not exceed 50kg.

- Transportation and protection

Handling tools

Use anti-static nylon straps or a vacuum suction cup to avoid direct contact with the crucible surface.

Do not allow metal tools (such as forklift teeth) to directly touch the crucible.

Operation Specifications

Wear clean gloves when handling to avoid contamination from hand grease.

Handle the crucible with care to prevent it from cracking or deforming due to impact.

- Storage Condition Parameters

Parameter requirements

Temperature 15℃-30℃ (avoid high temperature which may accelerate oxidation)

Humidity ≤ 50%RH

sunlight to prevent ultraviolet rays from accelerating aging

pressure (if vacuum packaging is required, the pressure should be ≤ 100Pa)

- Storage period and inspection

Storage period

Unopened molybdenum crucibles can be stored for more than 12 months under recommended conditions.

After opening, use within 6 months or reseal the package.

Regular inspection

Appearance inspection: Check every 3 months to confirm there are no oxidation spots, cracks or deformations.

Dimension inspection: Inspect key dimensions such as inner diameter and height once a year to ensure that the tolerance is within ± 0.1mm.

- Precautions for special scenarios

Long-term storage

The desiccant needs to be replaced regularly, and it is recommended to be replaced every 6 months.

Perform air tightness test every 12 months to ensure packaging integrity.

Transportation and storage

Shockproof packaging must be used during transportation to avoid severe vibration.

The transport vehicle must maintain a constant temperature (15℃-25℃) to avoid sudden temperature changes.

- Problem Solving

Surface oxidation

Minor oxidation can be removed by lightly sanding with fine sandpaper (600 grit or above).

Severe oxidation requires return to the factory for pickling or high-temperature reduction treatment.

Pollution treatment

Organic pollution can be wiped with ethanol or acetone, and metal pollution needs to be treated with a special cleaning agent.

- Storage taboos

It is forbidden to coexist with carbon-containing materials such as graphite and silicon carbide: carbonization reaction may occur at high temperature to generate Mo ₂ C (molybdenum carbide).

Avoid contact with sulfur-containing substances: Sulfides will react with molybdenum to form MoS₂ (molybdenum sulfide), which will reduce the performance of the material.

Do not stack on wet ground: Use wooden or plastic pallets for overhead storage.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

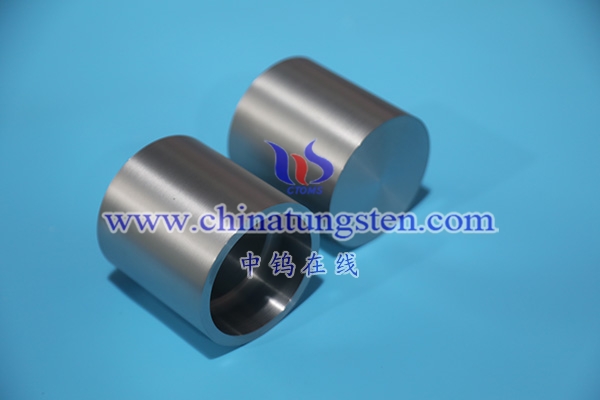

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595