Molybdenum crucibles may indeed face fatigue limit problems during high temperature, high pressure and thermal cycles. Fatigue limit refers to the maximum stress value that a material can withstand under repeated loads or thermal cycles. If this stress value is exceeded, the material may crack or fail.

For molybdenum crucibles, the following factors will lead to fatigue limit problems during use:

- Thermal Cycle Stress

At high temperatures, molybdenum crucibles will experience frequent temperature changes, especially during operation, the crucible may experience multiple cycles from low temperature to high temperature and then from high temperature to low temperature (such as heating, cooling, etc.). Each temperature change will cause uneven expansion or contraction of the inner and outer surfaces of the crucible, resulting in thermal stress.

If this thermal stress acts repeatedly on the molybdenum crucible, it may cause the material to gradually crack and even, in some cases, cause the crucible to break.

- Mechanical load

Molybdenum crucibles may be subjected to certain external mechanical loads during operation, such as pressure generated during transportation or placement.

Repeated exposure to mechanical shock or pressure over a long period of time, especially at high temperatures, may cause fatigue cracking of molybdenum materials.

- Oxidation and corrosion

When molybdenum is exposed to oxygen at high temperatures, especially in air, it is easy to oxidize to form molybdenum trioxide (MoO₃). This oxide layer may expand and contract with temperature changes, thereby generating additional thermal stress inside the crucible, further exacerbating fatigue.

If the molybdenum crucible is in an oxidizing environment for a long time, the formation and removal process of oxides may also affect the durability of the crucible and cause fatigue failure.

- Improper design and use

If the molybdenum crucible is not designed properly, or if the appropriate operating specifications are not followed during use (such as rapid temperature changes, overload use, etc.), fatigue damage may be aggravated. For example, uneven heating or cooling of the crucible during thermal cycles, or uneven contact between the outside of the crucible and the furnace wall, will lead to excessive local stress, thereby reducing fatigue life.

- Defects in the material itself

If there are material defects in the molybdenum crucible during the manufacturing process, such as microcracks or uneven organizational structure, these defects may become the starting points of fatigue cracks, resulting in fatigue failure of the molybdenum crucible under repeated thermal stress.

How to reduce fatigue problems:

Slow heating and cooling: Avoid rapid heating and cooling to reduce stress concentration caused by thermal shock.

Control the operating environment: Try to operate in an inert gas or vacuum environment to reduce the impact of oxidation on the material.

Reasonable design: Ensure that the crucible is designed to evenly distribute thermal stress and avoid excessive local stress.

the molybdenum crucible regularly for cracks or other damage during use , and replace any problematic crucibles in time.

Choose the right temperature range: Make sure the molybdenum crucible works within the appropriate temperature range to avoid exceeding its thermal stability.

======================================================================

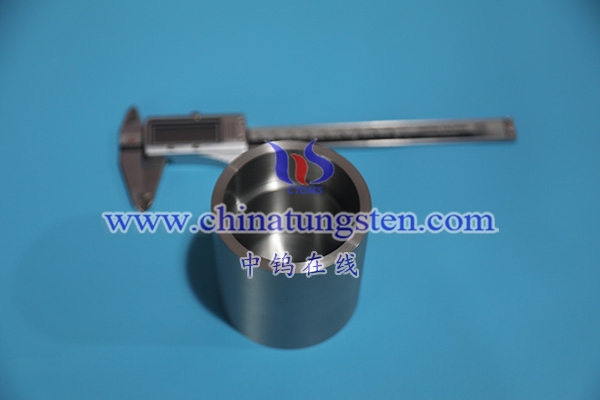

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595