The molybdenum crucible must be strictly controlled during the cooling process to avoid thermal stress damage, oxidation and structural deformation. The following are specific treatment methods and precautions:

- Cooling rate control

Principle: Cool down slowly to avoid thermal cracks or deformation caused by rapid cooling.

Recommended rate: ≤ 50℃/min (can be achieved by program-controlled furnace temperature or natural cooling).

Example: Cooling from 1800°C to room temperature requires ≥ 3 hours.

Segmented cooling:

Stage 1: High temperature section (> 1000℃) cooling at 30-50℃/min;

Stage 2: Medium temperature section (500-1000℃) cooling at 10-20℃/min;

Stage 3: Low temperature stage (< 500°C) can be cooled naturally or by forced ventilation.

- Cooling environment management

Inert gas protection:

Cool in an inert atmosphere such as argon or nitrogen to prevent oxidation.

Flow control: ≥ 5 L/min, ensuring the oxygen content in the furnace is < 10 ppm.

Vacuum cooling:

If the equipment supports it, vacuum cooling (vacuum degree ≤ 1×10 ⁻ ³ Pa) can be used to completely isolate oxygen.

Avoid water cooling:

Direct water cooling is prohibited, as it may cause the crucible to crack due to sudden cooling.

- Operation Specifications

Preheating and cooling symmetry:

The rates and paths of heating and cooling must be kept consistent to reduce thermal stress concentration.

Crucible placement:

Keep the crucible upright during cooling to avoid placing it sideways which may cause excessive local stress.

Cooling post-processing:

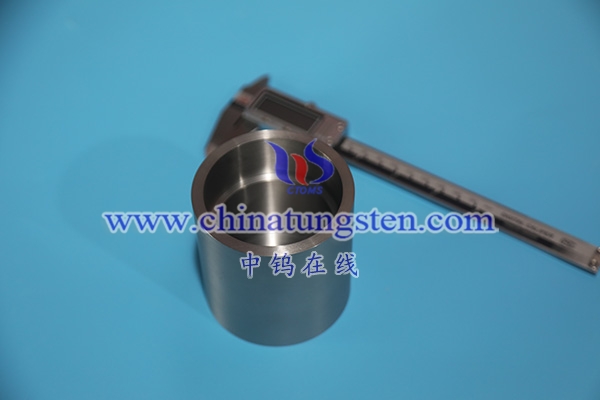

Surface inspection: After cooling to room temperature, visually inspect the crucible surface for cracks or deformation.

Dimensional measurement: Use a vernier caliper to measure key dimensions (e.g. wall thickness, diameter) to ensure that no irreversible deformation has occurred.

- Abnormal situation handling

| Anomalies | Possible causes | Countermeasures | Anomalies |

| crack | Rapid cooling or thermal stress | Scrap and re-evaluate cooling process | crack |

| Deformation | Uneven cooling rate | Adjust the cooling program and add segmented cooling steps | Deformation |

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595