The molybdenum crucible and the temperature control system need to be optimized from multiple dimensions such as temperature matching, control strategy, equipment selection and safety protection to ensure efficient and accurate process control. The following are the specific coordination methods and key points:

- Matching principle of temperature control system and molybdenum crucible

Temperature range matching

molybdenum crucible: ≤ 2000℃ (long-term use temperature ≤ 1800℃).

Temperature control system range: must cover the working temperature of the molybdenum crucible and leave a margin of 100-200℃.

Example: If the process needs to be carried out at 1600°C, the temperature control system should support 0-1800°C.

Heating rate matching

molybdenum crucible: ≤ 50℃/min (to avoid thermal stress cracking).

Temperature control system response speed: must support a temperature adjustment accuracy of ≤ 1°C/s.

- Collaborative control strategy of temperature control system and molybdenum crucible

Staged heating and cooling

Stage 1 (heating): slowly increase the temperature to 500°C at 10-30°C/min to avoid cracking of the molybdenum crucible.

Stage 2 (high temperature stage): Raise the temperature to the target temperature at 20-50℃/min and maintain constant temperature.

Stage 3 (cooling): Slowly cool at ≤ 50℃/min to avoid deformation caused by rapid cooling.

Closed-loop control

Feedback mechanism: The crucible temperature is monitored in real time by thermocouples and fed back to the temperature control system to adjust the power.

Example: If the target temperature is 1600°C, the temperature control system needs to be stably controlled within the range of ± 5°C.

Inert gas protection

Temperature control system linkage: when the temperature exceeds 800℃, argon or nitrogen protection is automatically started to prevent the molybdenum crucible from oxidation.

- Equipment selection and configuration

Heating equipment

Recommended Type:

Resistance furnace: suitable for processes ≤ 1800℃, low cost and uniform heating.

Induction furnace: suitable for high temperature processes of 1800-2000℃, with fast heating, but attention should be paid to the influence of electromagnetic fields on samples.

Thermostat

PID control: Proportional-integral-differential control algorithm to achieve precise temperature regulation.

High-precision sensor:

Accuracy: ± 0.1% FS (full scale accuracy).

Multi-stage program control: supports multi-stage program heating and a resolution of 0.1°C.

Multi-channel control: supports simultaneous control of multiple heating zones to meet complex process requirements.

sensor

Thermocouple Type:

Type K (0-1200℃): suitable for medium and low temperature range.

S type (0-1700℃): suitable for high temperature range.

Installation position: It needs to be close to the outer wall of the molybdenum crucible to avoid contact with the sample and affect the measurement accuracy.

- Safety protection and emergency measures

Over temperature protection

Temperature control system setting: When the temperature exceeds the set value by 10℃, the power supply will be automatically cut off.

Mechanical protection: Install a temperature limit switch for double protection.

Oxidation protection

Gas flow monitoring: Real-time monitoring of inert gas flow to ensure oxygen content < 10 ppm.

Pressure alarm: When the pressure inside the furnace is abnormal, it will automatically alarm and start emergency ventilation.

Crucible breakage detection

Acoustic wave detection: Monitor crucible cracks through acoustic wave sensors and provides early warning.

Visual inspection: Install a camera to monitor the crucible surface status in real time.

======================================================================

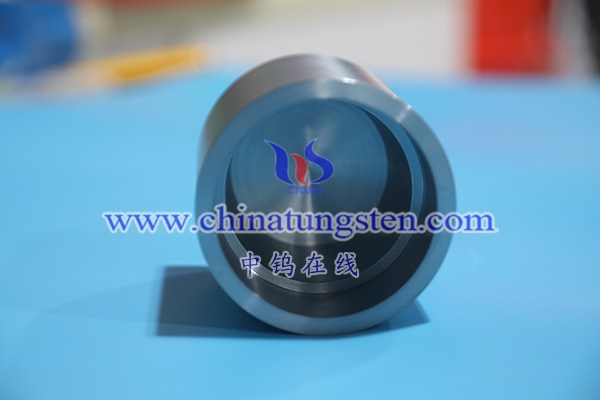

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595