Using molybdenum crucibles, there are some important requirements for operators to ensure a safe and efficient operation process and extend the service life of the molybdenum crucible. The following are the main operating requirements and precautions:

- High temperature operation knowledge

Temperature control: Operators must be familiar with the performance of molybdenum crucibles under different temperature conditions, especially the melting point and operating temperature range of molybdenum crucibles. Molybdenum crucibles need to be used with caution at high temperatures to avoid thermal shock caused by rapid temperature changes.

Preheating and cooling: The operator should preheat and cool the molybdenum crucible according to the conditions of use. Rapid heating or cooling may cause the crucible to crack, so slow temperature changes should be adopted to reduce thermal stress and fatigue.

- Operating environment control

Atmosphere control: Molybdenum crucibles are easily oxidized in the air. Operators should ensure that they are used in an inert gas environment (such as argon, nitrogen) or a vacuum environment to prevent the formation of an oxide layer that affects its performance. For high-purity smelting processes, the operating environment must be kept clean and pollution-free.

Furnace temperature and atmosphere inspection: Operators need to regularly check the furnace temperature, atmosphere and gas flow to ensure that the operating conditions meet the requirements to avoid damage to the molybdenum crucible or affect the experimental results.

- Wear appropriate protective equipment

High temperature protection: When operating the molybdenum crucible, a high temperature furnace or molten metal may be required, so the operator should wear appropriate protective clothing, gloves and goggles to prevent splashing, burns or other dangers of high temperature materials.

Respiratory protection: If the operation involves potentially volatile metal vapors (such as molybdenum vapor or molybdenum oxide vapor), the operator should wear appropriate respiratory protection equipment (such as a mask or air purifier) to avoid inhaling harmful gases.

- Operational Specifications

Avoid violent operation: Operators should avoid applying excessive mechanical force or impact to the molybdenum crucible. Crucibles at high temperatures are very fragile and may crack or break due to violent collisions or sudden temperature fluctuations.

Handle with care: During high temperature operation, be careful when handling the molybdenum crucible to avoid violent collisions between the crucible and other metals, tools or surfaces. Use suitable tools (such as pliers or hooks) to avoid direct contact.

- Maintenance and inspection

Regular inspection: Operators should regularly check the condition of the molybdenum crucible to see if there are any cracks, breakage, oxidation or other damage. If any problems are found, they should be replaced or repaired in time to avoid using damaged crucibles for experiments.

Cleaning and maintenance: After use, the molybdenum crucible should be cleaned to remove surface residues, oxides or slag to avoid affecting the performance of the next use. Operators should understand the cleaning method and perform appropriate maintenance according to the use of the molybdenum crucible.

- Prevent oxidation and contamination

Control oxygen exposure: Molybdenum crucibles are easily oxidized in the air, so operators should try to avoid long-term exposure to oxygen. During use, ensure that the molybdenum crucible is not in direct contact with the air, especially at high temperatures.

Prevent pollution: When using molybdenum crucibles, avoid external substances (such as grease, impurities, foreign matter, etc.) from contaminating the inner and outer surfaces of the crucible, keep it clean, and prevent affecting the accuracy of the experiment or the performance of the crucible.

- Training and security awareness

Professional training: Personnel operating molybdenum crucibles should undergo professional training and master the characteristics of molybdenum materials, operating procedures and safety knowledge. Especially when dealing with high temperatures and chemical reactions, operators should have sufficient safety awareness to avoid accidents.

Emergency response measures: Operators should be familiar with emergency response measures, such as fire, leakage, crucible breakage and other accidents, and be equipped with necessary emergency equipment (such as fire extinguishers, emergency flushing devices, etc.).

- Recording and Tracking

Experimental records: The operator should keep detailed records of each use of the molybdenum crucible, including the temperature, atmosphere, operation time, etc. These records will help with the management, maintenance and analysis of the crucible in the future.

Life cycle tracking: Regularly track the usage, loss and maintenance history of molybdenum crucibles to arrange replacement or repair in time.

======================================================================

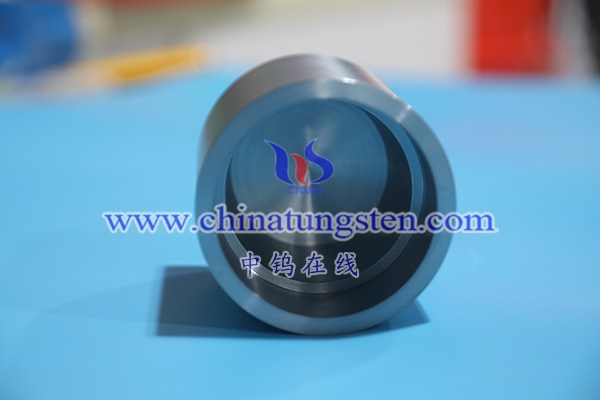

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595