Molybdenum crucibles can be reused, but the number of times and effectiveness of their reuse depends on many factors, including the use of the crucible, the degree of loss, and whether proper maintenance and treatment measures have been taken. The following are some key considerations for the secondary reuse of molybdenum crucibles:

- Inspection before reuse

Physical damage inspection: Before the molybdenum crucible is used again, it must be checked for cracks, breakage or obvious deformation. Any cracked or damaged crucible should be avoided from further use, as it may further deteriorate in subsequent use, leading to rupture or damage.

Oxidation layer inspection: When the molybdenum crucible is used at high temperature, an oxidation layer may be formed, which will affect its thermal conductivity and service life. For crucibles with severe oxidation, it is necessary to consider removing the oxidation layer through appropriate cleaning methods, or use it in an inert gas environment to prevent further deterioration of oxidation.

- Cleaning and maintenance

Surface cleaning: Before secondary use, the molybdenum crucible must be thoroughly cleaned to remove impurities such as residual slag, chemicals or oxides. Mechanical or chemical cleaning can be used, such as using sandpaper, abrasives or pickling to remove the surface oxide layer.

Prevent contamination: When reusing, make sure there are no contaminants on the inner and outer surfaces of the crucible to prevent affecting subsequent experiments or smelting processes. Keeping the crucible clean helps prevent contamination of molten metal or other materials.

- Precautions for recycling

Proper temperature control: When reusing, operators need to pay special attention to temperature control. In particular, the temperature should be raised slowly to avoid cracking or deformation of the crucible due to excessive thermal stress. The reuse of molybdenum crucibles needs to avoid excessive temperature differences and thermal shock.

Reduce oxidation and corrosion: To prevent the oxide layer from aggravating during use, molybdenum crucibles should be used in an inert gas environment as much as possible, especially at high temperatures, to reduce contact with oxygen in the air.

Suitable application scenarios: When reusing, make sure that the molybdenum crucible is suitable for the same or similar working environment and materials. For example, a molybdenum crucible may perform well in some metal smelting or chemical reactions, but it should not be used under some extreme conditions (such as highly corrosive atmospheres or strong chemical reactions).

- Factors affecting service life

Temperature and thermal cycle: The life of a molybdenum crucible is closely related to the temperature changes and thermal cycles it has experienced. Long-term thermal cycles may cause material fatigue, thereby reducing the structural strength of the crucible. Even for secondary use, attention should still be paid to the management of thermal cycles.

Material wear: Molybdenum crucibles may be worn during use due to friction or chemical reaction of molten metal. If the inner wall of the crucible is severely worn, it may affect its reuse effect.

- Reprocessing and repair

Repair method: If the damage to the molybdenum crucible is not serious, it can be repaired. The repair of the molybdenum crucible usually includes welding, grinding or polishing. When welding, it is necessary to select suitable filler materials, such as molybdenum alloy, to ensure the strength and heat resistance of the welded joint.

Proper reprocessing: During reprocessing, it is necessary to avoid excessive operation to avoid further damage to the crucible.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

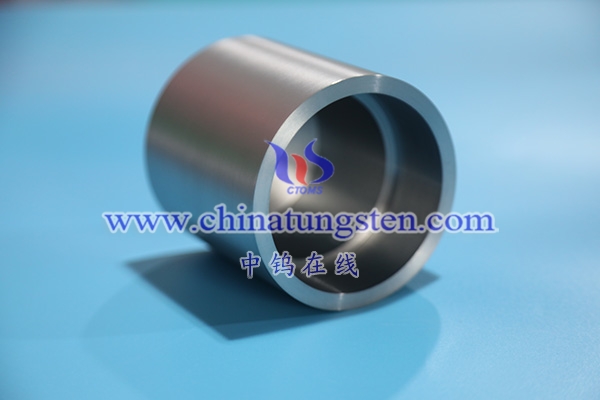

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595