The molybdenum crucible needs to be vacuum packaged and stored depends on the specific usage scenario and needs, but vacuum packaging is usually recommended under certain conditions to extend the service life and prevent oxidation. The following is a detailed analysis:

- Oxidation risk of molybdenum crucible

Oxidation Mechanism

Molybdenum begins to react with oxygen at temperatures above 400°C to form MoO₂ or MoO₃ oxide.

Temperature influence:

400-800℃: Slow oxidation to form a dense oxide film.

> 800℃: The oxidation rate increases sharply, the oxide film breaks, and the molybdenum matrix continues to be consumed.

Environmental impact:

Humidity: Water vapor accelerates oxidation, generating MoO₃ · nH₂O (molybdic acid).

Corrosive ions such as chloride ions (Cl⁻) accelerate the destruction of oxide films.

Oxidative effects

Structural damage: Oxidation causes the crucible wall thickness to decrease and the strength to drop.

Contamination risk: Oxidation products fall off and contaminate the sample.

Shortened service life: After the oxide film is destroyed, the molybdenum substrate is directly exposed and the oxidation rate increases exponentially.

- Necessity of vacuum packaging and preservation

Applicable scenarios

Recommended vacuum packaging:

Long-term storage (> 3 months).

High humidity environment (humidity > 60%).

Corrosive atmosphere (such as containing Cl₂, SO₂).

No vacuum packaging:

Short-term use (< 1 month).

Dry environment (humidity < 40%).

Inert gas protection (such as argon, nitrogen).

Advantages of vacuum packaging

Isolate from oxygen: Vacuum environment (< 1×10 ⁻ ³ Pa) effectively inhibits oxidation.

Prevent pollution: Avoid water vapor and corrosive gases from contacting the crucible.

Extended life: The oxidation rate is reduced by more than 90% (supported by experimental data).

- Vacuum Packaging Operation Suggestions

Packaging conditions

Vacuum degree: ≤ 1×10 ⁻ ³ Pa (avoid residual oxygen).

Packaging Materials:

First choice: aluminum foil composite film (moisture-proof and oxygen-blocking).

Alternative: Polytetrafluoroethylene (PTFE) bags (high temperature resistant).

Sealing method: heat sealing or vacuum packaging machine sealing.

Storage conditions

Temperature: Room temperature (20-25°C) or lower (such as refrigeration).

Humidity: ≤ 40% RH (can be used with desiccant).

Protect from light: Prevent ultraviolet rays from accelerating oxidation.

- Alternatives

Inert gas protection

Operation: Place the crucible in an argon or nitrogen atmosphere with an oxygen content < 10 ppm.

Applicability: Suitable for short-term storage or frequent use.

Surface coating

the crucible surface with aluminum oxide (Al₂O₃) or silicon nitride (Si₃N₄) coating.

Effect: Oxidation rate reduced by more than 50% (coating integrity needs to be checked regularly).

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

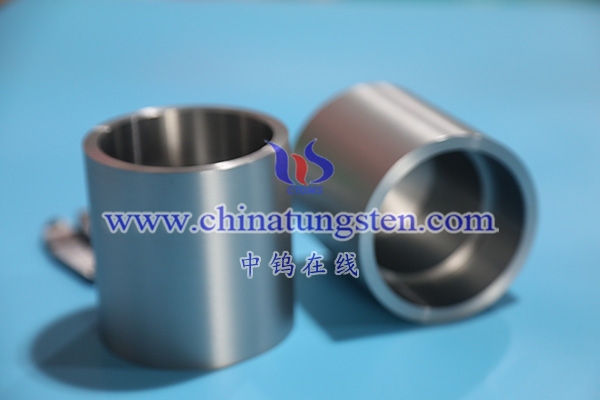

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595