The molybdenum crucible and the furnace body usually come from the potential difference or chemical reaction between the crucible and the furnace body at high temperature. This electrochemical corrosion may cause damage to the molybdenum crucible surface, performance degradation, and even shorten the service life. In order to avoid electrochemical corrosion between the molybdenum crucible and the furnace body, the following strategies can be adopted:

- Choose the right furnace material

Avoid materials that interact with molybdenum: It is very important to select furnace materials that are compatible with molybdenum. Metal materials that have a significant potential difference with molybdenum, such as iron or aluminum alloys, should be avoided, as these materials are prone to electrochemical reactions with molybdenum. It is best to choose high-temperature corrosion-resistant alloy materials, such as graphite or stainless steel, to avoid the formation of electrochemical corrosion cells.

Use of inert materials: Consider using some inert materials (such as platinum, tantalum, etc.) as furnace materials. These materials have low reactivity with molybdenum at high temperatures, thereby reducing the risk of electrochemical corrosion.

- Control the atmosphere in the furnace

Avoid oxidizing atmosphere: Avoid the presence of oxygen and other oxidizing gases in the furnace to reduce the occurrence of molybdenum oxide and prevent the formation of electrochemical corrosion reactions. Use inert gases such as argon and nitrogen in the atmosphere furnace to protect the crucible surface and prevent unnecessary reactions with the furnace body.

Control the humidity of the atmosphere: Moisture or water vapor will intensify the electrochemical corrosion reaction, so it is very important to control the humidity of the atmosphere in the furnace. The atmosphere should be kept as dry as possible to prevent moisture from reacting with the molybdenum surface.

- Avoid current paths

Electrical isolation: Ensure electrical isolation between the molybdenum crucible and the furnace body to avoid current paths due to potential differences. The flow of current can be avoided by adding insulating materials or using a support frame or isolation pad with good electrical insulation.

Avoid direct contact: Try to avoid direct contact between the molybdenum crucible and the furnace body, especially at high temperatures. Electrically insulating materials such as ceramics and quartz can be used as pads or supports to reduce the chance of direct contact and thus reduce the possibility of electrochemical corrosion.

- Use electrochemical protection measures

Cathodic protection: If the electrochemical corrosion problem is serious, cathodic protection measures can be considered. This method changes the electrochemical environment by applying an external current, thereby reducing the corrosion between the molybdenum crucible and the furnace body. This method is generally used for more demanding industrial applications.

Coating protection: Apply a protective coating (such as ceramic coating, carbon coating, etc.) to the surface of the molybdenum crucible to prevent direct contact with the corrosive substances in the furnace body and high temperature atmosphere, thereby reducing the occurrence of electrochemical corrosion.

- Optimize temperature control

Uniform heating and heating rate control: Avoid sudden temperature rise and fall. Rapid temperature change may cause uneven thermal stress between the crucible and the furnace, which in turn aggravates electrochemical corrosion. Controlling the appropriate heating rate (e.g. 1°C/min to 5°C/min) can ensure that the temperature of the crucible and the furnace changes more evenly, reducing contact and reaction caused by stress.

Reasonable setting of operating temperature: During operation, the temperature should be avoided to exceed the temperature resistance range of the molybdenum crucible. Excessive temperature may intensify the electrochemical reaction. Therefore, ensure that the operating temperature is controlled within the tolerance range of molybdenum to avoid overheating.

- Regular inspection and maintenance

Check the potential difference regularly: Check the potential difference between the molybdenum crucible and the furnace body regularly to ensure that no current path is generated. If a large potential difference or signs of corrosion are found, it should be inspected and repaired in time.

Crucible surface cleaning: Keep the surface of the molybdenum crucible clean to avoid slag, residues, etc. that affect the electrochemical behavior of the crucible surface. After use, clean the crucible thoroughly to remove any substances that may cause electrochemical reactions.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

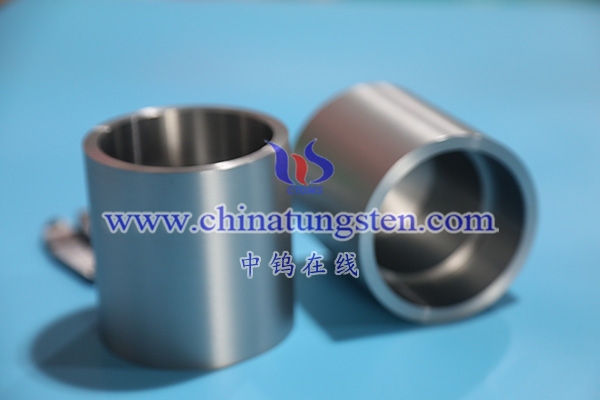

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595