Content

Chapter 1 Overview of molybdenum sheets

1.1 Molybdenum Sheet Definition

1.2 Specifications of molybdenum sheets

1.3 Characteristics of molybdenum sheets

1.3.1 Appearance characteristics of molybdenum sheets

1.3.1.1 Appearance and cause of black-brown molybdenum sheet

1.3.1.2 Silver-gray luster and treatment principle of Molybdenum sheets after alkali washing

1.3.1.3 Flatness of molybdenum sheet

Chapter 2 Performance of molybdenum sheets

2.1 Physical properties of molybdenum sheets

2.1.1 Density of molybdenum sheets

2.1.2 Melting point of molybdenum sheet

2.1.3 Boiling point of molybdenum sheet

2.1.4 Conductivity of molybdenum sheets

2.1.5 Thermal conductivity of molybdenum sheets

2.1.6 Coefficient of thermal expansion of molybdenum sheet

2.2 Mechanical properties of molybdenum sheets

2.2.1 High strength of molybdenum sheet

2.2.2 Ductility of molybdenum sheets

2.2.3 Creep resistance of molybdenum sheets at high temperatures

2.2.4 Hardness of molybdenum sheets

2.2.5 Toughness of molybdenum sheets

2.2.6 Fatigue resistance of molybdenum sheets

2.3 Chemical properties of molybdenum sheets

2.3.1 Corrosion resistance of molybdenum sheets

2.3.2 Oxidation resistance of molybdenum sheets

2.4 CTIA GROUP LTD Molybdenum Sheet MSDS

Chapter 3 Classification of molybdenum sheets

3.1 Classification of Molybdenum sheets by purity

3.1.1 High purity Molybdenum sheets (≥ 99.95% purity)

3.1.2 Ordinary purity Molybdenum sheets (99% – 99.9% purity)

3.2 Classification of molybdenum sheets according to the manufacturing process

3.2.1 Molybdenum sheets manufactured by powder metallurgy

3.2.2 Hot-rolled molybdenum sheets manufactured by rolling process

3.2.3 Cold-rolled molybdenum sheets manufactured by rolling process

3.3 Classification of molybdenum sheets according to application fields

3.3.1 Molybdenum sheets used in the electronic field

3.3.2 Molybdenum sheets used in the metallurgical industry

3.3.3 Molybdenum sheets used in the chemical industry

3.3.4 Molybdenum sheets used in the aerospace field

3.3.5 Molybdenum sheets used in other fields

Chapter 4 Molybdenum Sheet Production and Preparation Process

4.1 Preparation of raw materials before the production of molybdenum sheets

4.1.1 Types and characteristics of molybdenum ore

4.1.1.1 Characteristics and distribution of molybdenite

4.1.2 Mining and beneficiation methods of molybdenum ore

4.1.2.1 Molybdenum ore open-pit mining process and key points

4.1.2.2 Underground mining methods of molybdenum ore

4.1.2.3 Principles and processes of flotation method for molybdenum ore

4.1.2.4 Principles and processes of gravity separation method for molybdenum ore

4.1.2.5 Principles and processes of magnetic separation of molybdenum ore

4.1.3 Refining and conversion of molybdenum concentrate

4.1.3.1 Oxidative roasting-ammonia leaching refining process of molybdenum concentrate

4.1.3.2 Oxidative roasting-acid leaching refining process of molybdenum concentrate

4.1.3.3 Preparation of molybdenum powder from molybdenum concentrate extracts

4.2 Molding process of molybdenum sheet

4.2.1 Preparation of molybdenum sheets by powder metallurgy

4.2.2 Preparation of molybdenum sheet by rolling process

4.2.2.1 Preparation of molybdenum sheets by hot rolling process

4.2.2.2 Preparation of molybdenum sheets by cold rolling process

Chapter 5 Production and performance testing equipment for molybdenum sheets

5.1 Mining equipment for molybdenum ore

5.1.1 Open-pit mining equipment for molybdenum ore

5.1.2 Underground mining equipment for molybdenum ore

5.2 Mineral processing equipment for molybdenum ore

5.2.1 Crushing equipment for molybdenum ore

5.2.2 Grinding equipment for molybdenum ore

5.2.3 Grading equipment for molybdenum ore

5.2.4 Flotation equipment for molybdenum ore

5.3 Molding equipment for molybdenum sheets

5.3.1 Powder metallurgy equipment for Molybdenum sheets

5.3.1.1 Powder pressing equipment for molybdenum sheets

5.3.1.2 Sintering equipment for molybdenum sheets

5.3.2 Rolling equipment for molybdenum sheets

5.3.2.1 Hot rolling mills for molybdenum sheets

5.3.2.2 Cold rolling mill for molybdenum sheets

5.4 Performance testing equipment for molybdenum sheets

5.4.1 Density measuring equipment for molybdenum sheets

5.4.2 Melting point test equipment for molybdenum sheets

5.4.3 Conductivity test equipment for molybdenum sheets

5.4.4 Thermal conductivity test equipment for molybdenum sheets

5.5 Molybdenum sheet mechanical properties testing equipment

5.5.1 Universal material testing machine to test the mechanical properties of molybdenum sheets

5.5.2 The hardness tester tests the mechanical properties of molybdenum sheets

5.5.3 Impact testing machine to test the mechanical properties of molybdenum sheets

Chapter 6 Test methods for the performance of molybdenum sheets

6.1 Test method for density of molybdenum sheet

6.2 Test method for melting point of molybdenum sheet

6.3 Test methods for thermal stability of molybdenum sheets

6.4 Test method for conductivity of molybdenum sheet

6.5 Test method for thermal conductivity of molybdenum sheet

6.6 Test method for thermal expansion coefficient of molybdenum sheet

6.7 Test method for strength of molybdenum sheet

6.8 Test method for hardness of molybdenum sheet

6.9 Test methods for toughness of molybdenum sheets

6.10 Test method for the ductility of molybdenum sheets

6.11 Test methods for fatigue properties of molybdenum sheets

6.12 Test method for corrosion resistance of molybdenum sheets

6.13 Test methods for oxidation resistance of molybdenum sheets

Chapter 7 Application Fields of Molybdenum Sheets

7.1 Application of molybdenum sheet in the field of electronic information

7.1.1 Application of molybdenum sheets in semiconductors

7.1.2 Application of molybdenum sheet in electrode materials

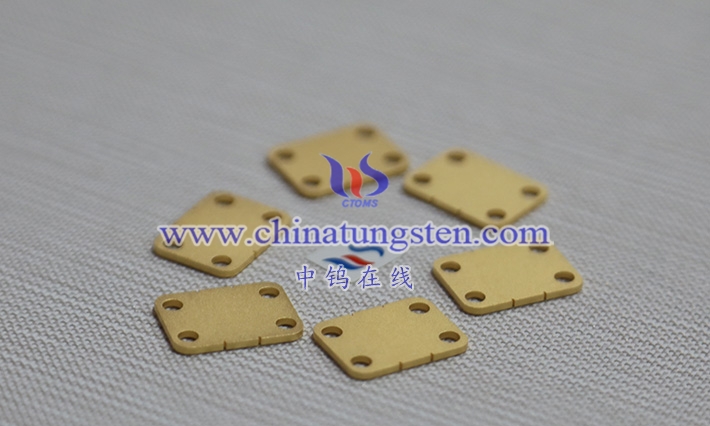

7.1.3 Application of molybdenum sheet in lead frame

7.2 Application of Molybdenum sheets in sapphire crystal growth furnace

7.2.1 Reflective screen in the sapphire crystal growth furnace for the production of Molybdenum sheets

7.2.2 Molybdenum sheets for the production of sapphire crystal growth furnace covers

7.3 Application of Molybdenum sheets in vacuum furnaces

7.3.1 Reflective screens in vacuum furnaces for the production of Molybdenum sheets

7.3.2 Heat in the vacuum furnace for the production of Molybdenum sheets

7.3.3 Connectors in vacuum furnaces for the production of Molybdenum sheets

7.4 Application of molybdenum sheet in plasma coating

7.4.1 Molybdenum sheet as a sputtering target for plasma coating

7.5 Application of molybdenum sheet in metallurgical industry

7.5.1 Application of Molybdenum sheets as additives in steelmaking

7.6 Application of molybdenum sheet in high-temperature furnace structure

7.6.1 Application of molybdenum sheet in heat shield

7.6.2 Application of molybdenum sheet in heating element

7.7 Application of molybdenum sheet in anti-corrosion of chemical equipment

7.7.1 Application of molybdenum sheet in reactor lining

7.7.2 Application of molybdenum sheet in pipe components

7.8 Application of molybdenum sheet in satellite components

7.8.1 Application of molybdenum sheet in antenna components

7.8.2 Application of molybdenum sheet in radiator of thermal control system

Chapter 8 Safety and Environmental Protection Problems in the Production of Molybdenum Sheets

8.1 Safety issues in the production of molybdenum sheets

8.2 Environmental problems in the production of molybdenum sheets

Chapter 9 Domestic and foreign standards for molybdenum sheets

9.1 Chinese National Standard for Molybdenum Sheets

9.2 International standards for molybdenum sheets

9.3 Molybdenum sheet standards in Europe, America, Japan, South Korea and other countries around the world

Chapter 10 Molybdenum Sheet Facts and Figures

10.1 What are the main facts of molybdenum tablets

10.2 All data of Molybdenum sheets (performance, production and application specifications)

Appendix: Multilingual Glossary of Molybdenum Chips (Chinese, English, Japanese, Korean)

References

Chapter 1 Overview of Molybdenum Tablets

1.1 Molybdenum Sheet Definition

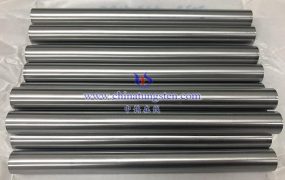

Molybdenum sheet is a thin sheet material made of high-purity molybdenum metal (the purity usually reaches more than 99.95%) through processes such as powder metallurgy, rolling or forging, and its appearance shows a silver-gray metallic luster. Molybdenum (chemical symbol Mo, atomic number 42) is a rare transition metal that occupies an important position in industry and science and technology due to its unique physical and chemical properties.

As a form of molybdenum metal processing, molybdenum sheet is usually presented in extremely thin thicknesses (ranging from 0.01 mm to 3 mm), and is widely used in aerospace, electronics industry, nuclear energy, medical equipment, and high-temperature stoves. Its high melting point (approx. 2620°C) and high strength make it excellent in extreme environments, especially in scenarios that require high temperature resistance and corrosion resistance. The manufacturing process of Molybdenum sheets typically involves extracting molybdenum from molybdenite (MoS₂) and then passing through multiple processes such as sintering, hot rolling, cold rolling, and annealing to make thin flakes with specific properties. This material not only plays an important role in traditional industries, but also shows irreplaceable value in emerging technology fields such as semiconductor manufacturing and new energy equipment.

1.2 Specifications of molybdenum sheets

The following is a table detailing the common specifications of molybdenum sheets, covering thickness, width, length, surface treatment type and related performance indicators to meet the needs of different industrial scenarios:

| parameter | Specification range | remark |

| thickness | 0.01 mm – 3 mm | Ultra-thin foils (0.01-0.1 mm) are used for high-precision electronic components, while thicker sheets (>1 mm) are used for structural parts |

| width | 50 mm – 600 mm | It can be customized according to customer needs, and some wide molybdenum sheets require special rolling equipment |

| length | Custom lengths or roll forms | The coil form is used for continuous production, and the cutting length depends on the application |

| Surface treatment | Polished, pickled, sandblasted | The polished side is suitable for semiconductors, the pickled side is used in a vacuum environment, and the sandblasted side enhances adhesion |

| Thickness tolerances | ± 0.005 mm – ±02 mm | Complies with ASTM B386, depending on thickness |

| Purity of the material | ≥99.95% | High-purity Molybdenum sheets can be doped with lanthanum, titanium and other elements (such as TZM alloys) to improve performance |

| Annealed state | Stress relief annealing, complete annealing | The annealing temperature is 1100-1300°C, which improves ductility and reduces brittleness |

| Surface roughness | Ra 0.8 μm–Ra 3.2μm | The roughness of the polished surface is the lowest, and the roughness of the sandblasted surface is higher |

READ MORE: What Is Molybdenum Sheet

===================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com|

Tel: +86 592 5129696 / 86 592 5129595