Directory

1.Introduction to TZM Molybdenum Rod

1.1 Definition and Importance of TZM Molybdenum Rod

1.2 Historical Development and Technological Evolution of TZM Molybdenum Rod

1.3 The Role of TZM Molybdenum Rod in Modern Industry and Scientific Research

2.Basic Principle of TZM Molybdenum Rod

2.1 Chemical Composition and Alloy Characteristics of TZM Molybdenum Rod

2.2 Physical and Mechanical Properties of TZM Molybdenum Rod

2.3 Comparison of TZM Molybdenum Rod with Pure Molybdenum and Other Superalloys

2.4 Working Mechanism of TZM Molybdenum Rod in High Temperature Environments

3.Performance of TZM Molybdenum Rod

3.1 Physical and Chemical Properties

3.1.1 Melting Point and Thermal Stability

3.1.2 Density and Thermal Conductivity

3.1.3 Oxidation and Corrosion Resistance

3.1.4 Mechanical Strength and Toughness

3.2 Thermal and Mechanical Properties

3.2.1 Thermal Expansion and High Temperature Deformation

3.2.2 Thermal Shock Resistance

3.2.3 Creep Performance and Long-Term Stability

3.2.4 Fatigue Performance and Recycling Ability

3.3 Microstructure-Property Relationship

3.3.1 Grain Structure and Orientation

3.3.2 The Role of Titanium, Zirconium, and Carbon

3.3.3 Surface Morphology and High Temperature Properties

3.4 Service Life and Reliability

3.4.1 Factors Affecting Service Life

3.4.2 Failure Mode Analysis (e.g., Fracture, Corrosion)

3.4.3 Reliability Testing Methods

3.5 CTIA GROUP LTD TZM Molybdenum Rod MSDS

4.Preparation Process and Technology

4.1 Raw Material Selection and Preparation

4.1.1 Molybdenum Powder Purification and Quality Requirements

4.1.2 Selection of Titanium, Zirconium, and Carbon Additives

4.1.3 Alloy Ratio Optimization

4.1.4 Raw Material Testing and Quality Control

4.2 Metallurgical Processes

4.2.1 Powder Mixing and Pressing

4.2.1.1 Mechanical Alloying

4.2.1.2 Isostatic Pressing

4.2.2 Sintering Process

4.2.2.1 Vacuum Sintering

4.2.2.2 Atmosphere Sintering and Temperature Control

4.2.3 Forging and Rolling

4.2.3.1 Hot and Cold Forging

4.2.3.2 Rolling Equipment and Parameters

4.2.4 Extrusion and Drawing

4.2.4.1 High-Temperature Extrusion

4.2.4.2 Drawing Dies and Lubrication

4.3 Machining and Finishing

4.3.1 Turning and Milling

4.3.1.1 CNC Machining

4.3.1.2 Machining Accuracy and Surface Roughness

4.3.2 Grinding and Polishing

4.3.2.1 Mechanical Polishing

4.3.2.2 Chemical and Electro-Polishing

4.3.3 Heat Treatment and Annealing

4.3.3.1 Annealing and Grain Control

4.3.3.2 Stress Relief Techniques

4.3.4 Surface Treatment

4.3.4.1 Antioxidation Coating Technology

4.3.4.2 Surface Carburizing and Nitriding

4.4 Equipment and Automation

4.4.1 Key Production Equipment

4.4.1.1 Vacuum Sintering Furnaces

4.4.1.2 Forging and Rolling Equipment

4.4.1.3 CNC Machining Centers

4.4.2 Production Line Automation and Intelligence

4.4.3 Cleanroom and Environmental Controls

5.Quality Control and Testing

5.1 Online Detection Technologies

5.1.1 Dimensional and Geometric Accuracy Testing

5.1.2 Surface Defect and Crack Inspection

5.2 Performance Testing

5.2.1 High Temperature Strength and Hardness

5.2.2 Corrosion and Oxidation Resistance

5.2.3 Thermal Expansion and Conductivity

5.3 Failure Analysis and Improvement

5.3.1 Crack and Fracture Analysis

5.3.2 High Temperature Fatigue and Creep

5.3.3 Quality Improvement Measures

6.Applications of TZM Molybdenum Rod

6.1 High-Temperature Furnace Components

6.1.1 Heating Elements

6.1.2 Vacuum Sintering Furnace Applications

6.1.3 Heat Treatment Furnace Applications

6.2 Aerospace Industry

6.2.1 Rocket Nozzle Applications

6.2.2 High-Temperature Structural Parts

6.2.3 Spacecraft Thermal Protection

6.3 Nuclear Industry

6.3.1 Nuclear Reactor Components

6.3.2 Nuclear Fusion Devices

6.3.3 Radioactive Material Handling

6.4 Electronics and Semiconductor Industry

6.4.1 Ion Implantation Equipment

6.4.2 Thin Film Deposition

6.4.3 Electronic Device Fabrication

6.5 Other Industrial and Research Fields

6.5.1 High-Temperature Experimental Equipment

6.5.2 High-Temperature Molds and Tools

6.5.3 Additive Manufacturing Applications

7.Technical Challenges and Future Development

7.1 Technical Challenges

7.1.1 Enhancing High-Temperature Oxidation Resistance

7.1.2 Complex Geometry and Scale-Up Manufacturing

7.1.3 Cost Control

7.2 New Materials and Technologies

7.2.1 Modified Alloy Design

7.2.2 Nanostructures and Composites

7.2.3 Competing High-Temperature Materials

7.3 Intelligent and Green Manufacturing

7.3.1 Smart Production Monitoring

7.3.2 Energy-Saving and Eco-Friendly Techniques

7.3.3 Efficient Waste Recycling

7.4 Future Trends

7.4.1 Performance Optimization

7.4.2 Cross-Industry Applications

7.4.3 Extreme Environment Applications

8.TZM Molybdenum Rod Standards and Specifications

8.1 National Standards (GB)

8.1.1 GB/T Standards for Molybdenum and Alloys

8.1.2 Superalloy Testing and Evaluation Standards

8.1.3 Process and Equipment Execution Standards

8.2 International Standards (ISO)

8.2.1 ISO 6892 – Tensile Testing of Metals

8.2.2 ISO 14001 – Environmental Management

8.2.3 ISO 3452 – Non-Destructive Testing

8.3 American Standards (US)

8.3.1 ASTM B387 – Molybdenum Alloy Bars

8.3.2 ASTM E384 – Microhardness Testing

8.3.3 ASME – High-Temperature Equipment Standards

8.4 Other International and Industry Standards

8.4.1 JIS G 0571 – Molybdenum Testing

8.4.2 DIN EN 10228 – Non-Destructive Testing

8.4.3 GOST 17431 – Molybdenum Alloys

8.5 Standard Implementation and Certification

8.5.1 Application of Standards in Production and Testing

8.5.2 Quality Management System Certification (e.g., ISO 9001)

8.5.3 Export Compliance and International Certifications

Appendix

1.Glossary of Terms

2.References

1.Introduction

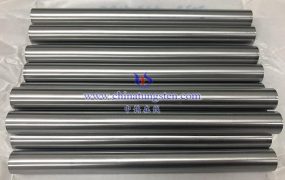

1.1 Definition and importance of TZM molybdenum rod

TZM molybdenum rod is a high-performance alloy material made of molybdenum (molybdenum) as a matrix and adding titanium (Ti), zirconium (Zr) and carbon (C) and other elements, and its name comes from the abbreviation of “Titanium-Zirconium-Molybdenum”. TZM molybdenum rod has an irreplaceable and important position in aerospace, nuclear industry, high-temperature furnace manufacturing, semiconductor industry and other high-tech fields due to its excellent high-temperature strength, excellent creep resistance and good corrosion resistance. Compared with pure molybdenum, TZM alloy significantly improves mechanical properties through the doping of trace elements, especially stability and durability in high-temperature environments, making it an ideal material choice under extreme working conditions.

The chemical composition of TZM molybdenum rods typically consists of about 0.5% titanium, 0.08% zirconium and 0.01-0.04% carbon, with the rest being molybdenum. This specific alloy ratio allows TZM molybdenum rods to have a higher recrystallization temperature at high temperatures (about 1400°C, much higher than the 1000°C of pure molybdenum), allowing them to maintain structural integrity in extreme environments. In addition, the oxidation resistance and thermal conductivity of TZM molybdenum rods are also superior to many traditional superalloys, making them excellent in scenarios requiring high thermal loads and mechanical strength.

In industrial applications, TZM molybdenum rods are widely used in the manufacture of heating elements for high-temperature furnaces, mold materials, aerospace components such as rocket nozzles and turbine blades, structural components for nuclear reactors, and components for semiconductor equipment. Its importance lies not only in its physical properties, but also in its ability to meet the growing demand for high-performance materials in modern industry. For example, in the aerospace sector, TZM molybdenum rods are the material of choice for the manufacture of high-temperature propulsion system components due to their high melting point (about 2623°C) and low coefficient of thermal expansion. In the nuclear industry, TZM molybdenum rods are used in the manufacture of key components in nuclear reactors due to their tolerance to neutron radiation and low thermal neutron absorption cross section.

In addition, TZM molybdenum rods also play an important role in the field of scientific research. For example, in high-temperature materials testing, plasma physics research, and advanced manufacturing technology development, TZM molybdenum rods are used as the core components of experimental equipment due to their stable properties. The study shows that the production process and quality control technology of TZM molybdenum rod have been continuously improved in recent years, which has promoted its wide application in the global market. From aerospace to the energy industry, TZM molybdenum rods have become an indispensable part of the modern high-tech industry, and their importance continues to increase with technological advancements and the expansion of application fields.

1.2 Historical development and technological evolution of TZM molybdenum rod

The development of TZM molybdenum rods dates back to the mid-20th century, when the demand for high-temperature materials increased dramatically with the rapid development of the aerospace and nuclear industries. Although pure molybdenum has a high melting point and good electrical and thermal conductivity, its lack of high temperature strength, creep and recrystallization and embrittlement limit its application in extreme environments. To overcome these shortcomings, materials scientists began to explore alloying to improve the properties of molybdenum.

In the 50s of the 20th century, scientific research institutions and industry in the United States took the lead in developing TZM alloys. By adding trace amounts of titanium, zirconium and carbon to the molybdenum matrix, TZM alloys significantly improve their high-temperature strength and creep resistance. The addition of titanium and zirconium enhances the crystal structure of molybdenum through solution strengthening and second-phase strengthening mechanisms, while the addition of carbon further improves the strength and wear resistance of the alloy through the formation of carbide particles. At the end of the 1950s, TZM alloys began to be used in the aerospace sector, for example in the manufacture of rocket engine nozzles and high-temperature structural components.

In the 60s of the 20th century, with the progress of powder metallurgy technology, the production process of TZM molybdenum rod has been significantly improved. The powder metallurgy method makes the microstructure of TZM alloy more uniform and the performance more stable by precisely controlling the particle size and mixing ratio of the raw powder. During this period, TZM molybdenum rods began to be widely used in high-temperature furnace manufacturing and the nuclear industry. For example, control rods and structural parts in nuclear reactors began to use TZM alloys to cope with high temperatures and high radiation environments.

From the 70s to the 80s of the 20th century, with the rise of the semiconductor industry, the application field of TZM molybdenum rod was further expanded. Due to their high thermal conductivity and low coefficient of thermal expansion, TZM molybdenum rods are used in the manufacture of high-temperature fixtures and sputtering targets in semiconductor devices. During the same period, demand in the aerospace sector drove further optimization of TZM molybdenum rods, for example by improving the heat treatment process and surface treatment technology to enhance their oxidation resistance.

In the 21st century, the production and application technology of TZM molybdenum rod has entered a new stage. Studies have shown that the production process of modern TZM molybdenum rods has achieved a high degree of automation and precision. For example, through advanced plasma sintering technology and vacuum heat treatment process, the grain size and performance consistency of TZM molybdenum rods have been significantly improved. In addition, the introduction of nanotechnology has further optimized the microstructure of TZM alloys, thereby improving their durability in extreme environments.

In recent years, with the development of additive manufacturing (3D printing) technology, the application potential of TZM molybdenum rod has been further explored. Researchers began to explore the direct fabrication of complex TZM alloy parts through technologies such as laser selective melting (SLM), which not only reduced production costs, but also expanded the application prospects of TZM molybdenum rods in aerospace and medical devices. For example, 3D-printed TZM alloy parts can be used to make rocket nozzles or high-temperature molds with complex geometries.

1.3 The role of TZM molybdenum rod in modern industry and scientific research

In modern industry and scientific research, TZM molybdenum rods play multiple roles due to their unique combination of properties. First of all, in the aerospace field, TZM molybdenum rods are widely used in the manufacture of rocket engine nozzles, turbine blades, and high-temperature structural parts. For example, companies such as SpaceX have adopted TZM alloys in their rocket engine designs to cope with the high temperature and high pressure environment at the combustion chamber and nozzles. Chinatungsten Online’s technical data shows that the excellent performance of TZM molybdenum rods in these applications is due to their high melting point and low coefficient of thermal expansion, which can maintain structural stability under extreme heat loads.

In the nuclear industry, TZM molybdenum rods are used in the manufacture of structural components and control rods of nuclear reactors due to their excellent radiation resistance and high temperature stability. The high temperature and intense radiation environment inside a nuclear reactor place extremely high demands on the material, and the low thermal neutron absorption cross section and high strength of TZM molybdenum rods make them an ideal choice. In addition, TZM molybdenum rods are used in the manufacture of plasma-facing materials (PFMs) for nuclear fusion reactors to cope with extreme heat and particle bombardment.

In the field of high-temperature furnace manufacturing, TZM molybdenum rods are widely used as heating elements, supports and crucible materials. Due to its high recrystallization temperature and excellent creep resistance, TZM molybdenum rods are able to operate stably for a long time in high-temperature environments above 1600°C. For example, in vacuum furnaces and atmosphere protection furnaces, TZM molybdenum rods are used in the manufacture of heating elements and thermocouple protective sleeves to ensure the reliability and durability of equipment at high temperatures.

In the semiconductor industry, TZM molybdenum rods are used as sputtering targets and high-temperature fixtures due to their high thermal conductivity and low coefficient of thermal expansion. For example, in the physical vapor deposition (PVD) process, TZM molybdenum rods are used as targets for depositing high-performance thin films. In addition, TZM molybdenum rods are also used in the manufacture of key components in ion implantation devices to meet the requirements of high precision and stability in semiconductor manufacturing.

In the field of scientific research, TZM molybdenum rods are widely used in high-temperature materials testing, plasma physics research and advanced manufacturing technology development. For example, in high-temperature materials testing, TZM molybdenum rods are used as specimen grips and heating elements to simulate material properties under extreme operating conditions. In plasma physics research, TZM molybdenum rods are used as structural materials for experimental setups due to their excellent plasma erosion resistance. In addition, TZM molybdenum rods also show great potential in the field of additive manufacturing, and researchers are exploring the use of 3D printing technology to fabricate TZM alloy parts with complex shapes to meet the special needs of the aerospace and medical fields.

Chinatungsten Online’s WeChat official account “Chinatungsten Online” reported that the global market demand for TZM molybdenum rods has continued to grow in recent years, especially in the Asia-Pacific region. With the rapid development of China, India and other countries in the field of aerospace and nuclear industry, the application prospect of TZM molybdenum rod is broader. In the future, with the advancement of new material technology, TZM molybdenum rods are expected to play an important role in more fields, such as in renewable energy equipment (such as high-temperature solar collectors) and biomedical fields (such as high-temperature sterilization equipment).

READ MORE: Encyclopedia of TZM Molybdenum Rod

===================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com|

Tel: +86 592 5129696 / 86 592 5129595