Directory

Chapter 1: Introduction

1.1 Definition and Overview of Molybdenum Wire

1.2 History and Development of Molybdenum Wire

1.3 The Importance of Molybdenum Wire in Modern Industry

1.4 Current Status of Research and Application of Molybdenum Wire

Chapter 2: Classification of Molybdenum Wire

2.1 Classification by Chemical Composition

2.1.1 Pure Molybdenum Wire

2.1.2 Molybdenum Lanthanum Wire

2.1.3 Molybdenum Rhenium Wire

2.1.4 Other Alloy Molybdenum Wires

2.2 Classification by Use

2.2.1 Molybdenum Wire for Electric Light Source

2.2.2 Molybdenum Wire for Wire Cutting

2.2.3 Molybdenum Wire for Spraying

2.2.4 Molybdenum Wire for Vacuum Coating

2.2.5 Molybdenum Wire for Heating Elements

2.2.6 Molybdenum Wire for High-Temperature Furnace Components

2.2.7 Molybdenum Wire for Electronic Components

2.2.8 Molybdenum Wire for Medical and Aerospace Use

2.3 Classification by Surface State

2.3.1 Black Molybdenum Wire

2.3.2 Cleaned molybdenum wire

2.4 Classification by Processing Method

2.4.1 Hot Drawn Molybdenum Wire

2.4.2 Cold-Drawn Molybdenum Wire

2.4.3 Precision Molybdenum Wire

2.5 Classification by Specification

2.5.1 Ultra-Fine Molybdenum Wire (Diameter < 0.05 mm)

2.5.2 Standard Fine Molybdenum Wire (0.05–0.3 mm)

2.5.3 Medium-Coarse Molybdenum Wire (0.3–1.0 mm Diameter)

2.5.4 Coarse Molybdenum Wire (Diameter > 1.0 mm)

Chapter 3: Characteristics of Molybdenum Wire

3.1 Physical Properties of Molybdenum Wire

3.1.1 Melting Point and Boiling Point of Molybdenum Wire

3.1.2 Density of Molybdenum Wire

3.1.3 Coefficient of Thermal Expansion of Molybdenum Wire

3.1.4 Conductivity of Molybdenum Wire

3.1.5 Thermal Conductivity of Molybdenum Wire

3.1.6 Mohs Hardness of Molybdenum Wire

3.2 Chemical Properties of Molybdenum Wire

3.2.1 Chemical Stability of Molybdenum Wire

3.2.2 Corrosion Resistance of Molybdenum Wire

3.2.3 Oxidation Characteristics of Molybdenum Wire

3.2.4 Valency and Chemical Reaction of Molybdenum Wire

3.3 Mechanical Properties of Molybdenum Wire

3.3.1 Tensile Strength of Molybdenum Wire

3.3.2 Ductility of Molybdenum Wire

3.3.3 Toughness of Molybdenum Wire

3.3.4 Fatigue Properties of Molybdenum Wire

3.4 Special Properties of Molybdenum Wire

3.4.1 High Temperature Performance of Molybdenum Wire

3.4.2 Abrasion Resistance of Molybdenum Wire

3.4.3 Non-Magnetic Properties of Molybdenum Wire

3.5 CTIA GROUP LTD Molybdenum Wire MSDS

Chapter 4: Preparation and Production Technology of Molybdenum Wire

4.1 Preparation of Raw Materials

4.1.1 Beneficiation and Purification of Molybdenum Concentrate

4.1.2 Production of Molybdenum Powder

4.1.3 Alloying Element Addition

4.2 Powder Metallurgy Process

4.2.1 Molybdenum Powder Pressing and Molding

4.2.2 Sintering Process

4.2.3 Blank Preparation

4.3 Wire Drawing

4.3.1 Hot Wire Drawing Technology

4.3.2 Cold Drawing Technology

4.3.3 Multi-Pass Drawing

4.3.4 Lubrication and Cooling Technology

4.4 Surface Treatment

4.4.1 Caustic Washing Process (Cleaned molybdenum wire)

4.4.2 Polishing Process

4.4.3 Coating Treatment

4.5 Heat Treatment and Annealing

4.5.1 Annealing Process Parameters

4.5.2 Heat Treatment Equipment

4.6 Preparation of Special Alloy Molybdenum Wire

4.6.1 Doping Process of Lanthanum Molybdenum Wire

4.6.2 Production of Molybdenum-Rhenium Alloy Wire

4.7 Process Optimization and Technological Innovation

4.7.1 Automated Production Technology

4.7.2 Environmental Protection and Energy-Saving Processes

Chapter 5: Uses of Molybdenum Wire

5.1 Molybdenum Wire for Electric Light Source

5.1.1 Support Wires and Leads in the Manufacture of Light Bulbs

5.1.2 Electrode Materials for Halogen and Fluorescent Lamps

5.1.3 LED Lamp Base and Connecting Material

5.2 Molybdenum Wire for Wire Cutting

5.2.1 Wire Wire for Wire EDM Machine Tools

5.2.2 Cutting Non-Ferrous Metals, Steel and Cemented Carbide

5.2.3 Precision Molds and Complex Shape Processing

5.3 Molybdenum Wire for Spraying

5.3.1 Wear-Resistant Coatings for Automotive Parts

5.3.2 Surface Repair and Strengthening of Mechanical Components

5.3.3 Thermal Spraying of Aero-Engine Components

5.4 Molybdenum Wire for Vacuum Coating

5.4.1 Evaporation Source Materials in Thin Film Deposition

5.4.2 Optical and Decorative Coatings

5.4.3 Semiconductor and Solar Cell Coatings

5.5 Molybdenum Wire for Heating Elements

5.5.1 Heating Wire for High-Temperature Electric Furnace

5.5.2 Heating Elements in Vacuum Furnaces and Atmosphere Furnaces

5.5.3 Applications in Heat Treatment Equipment

5.6 Molybdenum Wire for High-Temperature Furnace Components

5.6.1 Supporting and Fixing Components of High-Temperature Furnaces

5.6.2 Leads and Shielding Parts of Vacuum Furnaces

5.6.3 Structural Materials for Crystal Growth Furnaces

5.7 Molybdenum Wire for Electronic Components

5.7.1 Vacuum Electronics (Tubes, X-Ray Tubes)

5.7.2 Manufacture of Thermocouples and Sensors

5.7.3 Connecting Materials for Microelectronics and Integrated Circuits

5.8 Molybdenum Wire for Medical and Aerospace Use

5.8.1 High-Temperature Components in Medical Devices (e.g. X-Ray Targets)

5.8.2 High-Temperature and Corrosion-Resistant Structural Parts of Spacecraft

5.8.3 Minimally Invasive Surgical Tools and Implant Materials

Chapter 6: Molybdenum Wire Production Equipment

6.1 Raw Material Handling Equipment

6.1.1 Mineral Processing Equipment

6.1.2 Molybdenum Powder Production Equipment

6.2 Powder Metallurgy Equipment

6.2.1 Presses

6.2.2 Sintering Furnaces

6.3 Wire Drawing Equipment

6.3.1 Wire Drawing Machines

6.3.2 Moulds and Lubrication Systems

6.4 Heat Treatment Equipment

6.4.1 Annealing Furnaces

6.4.2 Vacuum Furnaces

6.5 Surface Treatment Equipment

6.5.1 Caustic Washing Equipment

6.5.2 Polishing and Coating Equipment

6.6 Testing and Quality Control Equipment

6.6.1 Eddy Current Flaw Detection Equipment

6.6.2 Tensile Testing Machines

6.6.3 Microscopes and Spectrometers

6.7 Automation and Intelligent Equipment

6.7.1 Automatic Wire Drawing Production Line

6.7.2 On-Line Monitoring System

Chapter 7: Molybdenum Wire Standards

7.1 Domestic Standard for Molybdenum Wire

7.1.1 GB/T 4182-2003《Molybdenum Wire》

7.1.2 GB/T 3462-2007

7.1.3 Other Relevant National Standards

7.2 International Standards for Molybdenum Wire

7.2.1 ASTM B387 Standard for Molybdenum and Molybdenum Alloy Rods, Bars and Wires

7.2.2 ISO Standards

7.2.3 Other International Standards (e.g. JIS, DIN)

7.3 Molybdenum Wire Industry Standard

7.3.1 National Technical Committee for Standardization of Nonferrous Metals (TC243)

7.3.2 Internal Standards

7.4 Comparison and Analysis of Molybdenum Wire Standards

7.4.1 Differences Between Domestic and Foreign Standards

7.4.2 Applicability and Limitations of Standards

Chapter 8: Detection Methods of Molybdenum Wire

8.1 Molybdenum Wire Chemical Composition Testing

8.1.1 Spectral Analysis (ICP-MS, XRF)

8.1.2 Chemical Titration

8.2 Testing of Physical Properties of Molybdenum Wire

8.2.1 Tensile Strength Test

8.2.2 Elongation Test

8.2.3 Hardness Test

8.3 Molybdenum Wire Surface Quality Inspection

8.3.1 Microscopic Observation

8.3.2 Eddy Current Flaw Detection

8.3.3 Surface Roughness Test

8.4 Molybdenum Wire Size and Tolerance Testing

8.4.1 Laser Caliper

8.4.2 Micrometers and Micromeasurements

8.5 Other Tests of Molybdenum Wire

8.5.1 High Temperature Resistance Test

8.5.2 Corrosion Resistance Test

8.5.3 Electrical Performance Test

8.6 Identification Method of Waste Molybdenum Wire

8.6.1 Burn Test

8.6.2 Magnetic Test

8.6.3 Concentrated Nitric Acid Test

8.6.4 Weight and Elasticity Checks

Chapter 9: Molybdenum Wire Market and Development Trend

9.1 Overview of the Global Molybdenum Wire Market

9.1.1 Major Producing Countries

9.1.2 Market Demand and Supply

9.2 Domestic Molybdenum Wire Market

9.2.1 Major Manufacturers (e.g. Chinatungsten Manufacturing)

9.2.2 Market Share and Competitive Landscape

9.3 Development Trend of Molybdenum Wire

9.3.1 Development of New Materials and Processes

9.3.2 Intelligent Manufacturing and Quality Traceability Technology

9.3.3 Development of New Molybdenum Alloy Wires

9.3.4 Development of Degradable or Alternative Materials

9.3.5 New Application Prospects of Molybdenum Wire in New Energy, 5G and Medical Direction

Chapter 10: Molybdenum Wire Environment and Safety

10.1 Environmental Impact of Molybdenum Wire Production

10.1.1 Waste Gas and Wastewater Treatment

10.1.2 Solid Waste Management

10.2 Safety Specifications for Molybdenum Wire Production

10.2.1 Safety of High-Temperature Operation

10.2.2 Safe Use of Chemicals

10.3 Recycling and Reuse of Waste Molybdenum Wire

10.3.1 Recycling Process

Appendix

- Glossary of Terms

- References

Chapter 1 Introduction

1.1 Definition and overview of molybdenum wire

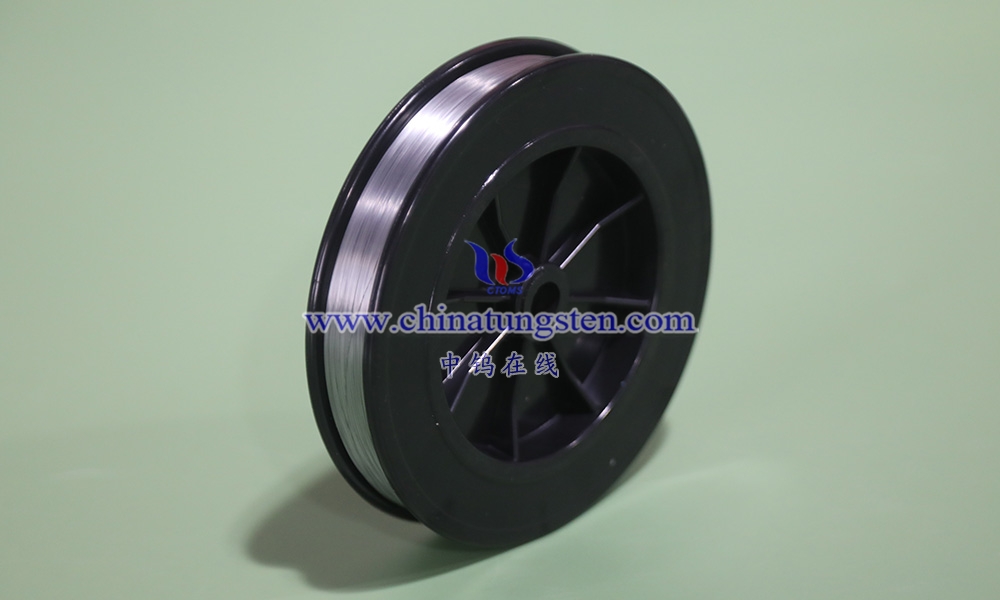

Molybdenum wire is a kind of filament-like material made of molybdenum metal or its alloy, through powder metallurgy, wire drawing, heat treatment and other processes, usually with a diameter of between 0.03 mm and several mm. Molybdenum (chemical symbol Mo, atomic number 42) is a high melting point, transition metal with excellent physical, chemical and mechanical properties, such as high strength, high temperature resistance, corrosion resistance and good electrical and thermal conductivity. These characteristics make molybdenum wire an irreplaceable role in a variety of industrial fields. Molybdenum wire can be divided into pure molybdenum wire (purity usually ≥ 99.95%) and molybdenum alloy wire (such as lanthanum molybdenum wire, molybdenum-rhenium alloy wire, etc.), which can be divided into black molybdenum wire (without alkali washing, the surface oxide layer is black-gray) and cleaned molybdenum wire (after alkali washing or polishing, the surface is silvery-white) according to the surface state. Molybdenum wire is available in a variety of specifications, from ultra-fine molybdenum wire (diameter < 0.1 mm) to coarse molybdenum wire (diameter > 1.0 mm), to meet the needs of different applications.

The production process of molybdenum wire is complex, involving multiple processes from molybdenum concentrate purification to wire drawing, and its core is to control the grain structure and surface quality to ensure performance stability. Molybdenum wire is used in a wide range of applications, including wire EDM, electric light sources, vacuum coatings, high-temperature furnace components, electronic component manufacturing, and medical and aerospace applications. Molybdenum wire’s high melting point (about 2623°C) and low coefficient of thermal expansion make it excellent in high temperatures and extreme environments, while its good conductivity and chemical stability make it an important position in precision machining and electronics industries. In addition, molybdenum wire is also environmentally friendly and recyclable, and waste molybdenum wire can be re-refined through the recycling process, which meets the requirements of modern green manufacturing.

1.2 History and development of molybdenum wire

Molybdenum, as a rare metal, has a history of discovery and application dating back to the end of the 18th century. In 1778, the Swedish chemist Carl Wilhelm Scheele isolated the molybdenum element for the first time and named it “Molybdenum”, derived from the Greek word “molybdos”, which means “similar to lead”, because its ore looks similar to lead ore. In 1790, another Swedish chemist, Peter Jacob Hjelm, prepared molybdenum metal by reducing molybdenum acid, laying the foundation for subsequent applications. However, due to the high melting point and processing difficulty of molybdenum, its application was limited in the early days and was mainly used for laboratory research.

In the late 19th and early 20th centuries, with the growth of metallurgical technology and the demand for high-temperature materials, molybdenum began to enter the industrial field. In the early 1900s, molybdenum was discovered as an alloying element to significantly improve the strength and corrosion resistance of steel, and molybdenum steel began to be used in weapons manufacturing and the machine industry. The development of molybdenum wire is closely related to the rise of the electric light source industry. In 1910, William M. William D. Coolidge developed tungsten filament bulbs at General Electric Company in the United States, and molybdenum wire was used as a support wire and lead material for bulbs because of its similar high-temperature resistance and lower cost to tungsten. Since then, the application of molybdenum wire has gradually expanded to other fields, such as vacuum electronics and high-temperature stoves.

In the middle of the 20th century, the emergence of EDM technology further promoted the development of molybdenum wire. In the 1950s, China began to explore the application of molybdenum wire in wire EDM, and with its high strength and arc erosion resistance, molybdenum wire became an ideal electrode material for wire cutting machine tools. In the 21st century, with the progress of nanotechnology, precision manufacturing and aerospace industry, the preparation process of molybdenum wire has been continuously optimized, and the development of ultra-fine molybdenum wire and alloy molybdenum wire (such as lanthanum molybdenum wire and molybdenum rhenium alloy wire) has significantly improved its performance. For example, Chinatungsten Online reported that in recent years, China’s molybdenum wire production technology has reached the international advanced level, and breakthroughs have been made in the drawing technology and doping process of ultra-fine molybdenum wire (diameter <0.02 mm) to meet the needs of microelectronics and medical fields.

1.3 The importance of molybdenum wire in modern industry

Molybdenum wire has an irreplaceable position in modern industry because of its unique combination of properties. First of all, molybdenum wire’s high melting point and excellent high-temperature stability make it the material of choice for high-temperature environments. For example, in high-temperature vacuum furnaces, molybdenum wire is used as a heating element and support member, which can operate stably for a long time at temperatures in excess of 2000°C. Secondly, the excellent conductivity and arc erosion resistance of molybdenum wire make it widely used in wire EDM, which can efficiently cut high-hardness materials such as cemented carbide and titanium alloy, and is widely used in precision mold and aerospace parts processing. Chinatungsten Online pointed out that China, as the world’s largest producer of molybdenum wire, accounts for more than 70% of the global market share of molybdenum wire for wire cutting.

In the field of electric light sources, molybdenum wire is used as a support wire and lead for light bulbs due to its good thermal compatibility with glass and high temperature resistance, especially in halogen and fluorescent lamps. In addition, molybdenum wire also plays an important role in the field of vacuum coating and thermal spraying. For example, molybdenum wire can be used as an evaporation source material to deposit optical and semiconductor films; In thermal spraying, molybdenum wire spray coating can significantly improve the wear resistance of automotive piston rings and aero engine components. Molybdenum wire is also used in thermocouples, X-ray tubes, and microelectronic wires in the manufacture of electronic components, where its high purity and low impurity content ensure high reliability of the device.

In the medical and aerospace fields, the application of molybdenum wire cannot be ignored. The high strength and biocompatibility of molybdenum wire allow it to be used in the manufacture of X-ray targets and minimally invasive surgical tools; Molybdenum-rhenium alloy wire is widely used in high-temperature structural parts of spacecraft due to its excellent corrosion resistance and high-temperature strength. In addition, the application of molybdenum wire in the field of new energy is also increasing, such as electrode materials and catalyst carriers for solar cells, helping the development of green energy. In summary, the versatility and high performance of molybdenum wire make it a pillar material for modern industry, which is widely used in strategic industries such as machinery manufacturing, electronics, energy, medical and aerospace.

1.4 Current status of research and application of molybdenum wire

At present, the research and application of molybdenum wire is in a stage of rapid development, and a large number of research has been carried out around the material science, process technology and application fields of molybdenum wire worldwide. In materials science, research focuses on improving the strength, toughness, and high-temperature properties of molybdenum wire. For example, molybdenum wire doped with rare earth elements (e.g., lanthanum, yttrium) significantly increases the recrystallization temperature and tensile strength, making it suitable for more demanding high-temperature environments. The development of molybdenum rhenium alloy wire further expands the application of molybdenum wire in extreme environments, such as spacecraft nozzles and high-temperature sensors. According to the research, Chinese scientific research institutions have made breakthroughs in the preparation technology of nanoscale molybdenum wire in recent years, and the tensile strength of ultra-fine molybdenum wire can reach more than 3000 MPa by controlling the grain size and surface defects, which is close to the theoretical limit.

In terms of production process, the preparation technology of molybdenum wire has developed from the traditional powder metallurgy and wire drawing process to the direction of intelligence and green. The application of automatic wire drawing production line and online monitoring system improves production efficiency and product quality stability. At the same time, the introduction of environmentally friendly processes, such as low-energy sintering and wastewater recycling, reduces the environmental impact of molybdenum wire production. In addition, the recycling technology of waste molybdenum wire has also become a research hotspot, and the chemical dissolution method and electrolytic recovery method can efficiently extract molybdenum metal, with a recovery rate of more than 90%.

In terms of application fields, the demand for molybdenum wire in high value-added industries continues to grow. The demand for high-precision molybdenum wire in the field of wire EDM has driven the development of ultra-fine molybdenum wire to meet the requirements of micron processing. In the field of new energy, molybdenum wire is used as an electrode material for solar cells and fuel cells, with an average annual growth rate of more than 10%. The demand for molybdenum-rhenium alloy wire in the aerospace sector is also increasing, especially in high thrust-to-weight ratio engines and deep space exploration equipment. Research in the medical field focuses on the application of molybdenum wire in biosensors and implantable medical devices, taking advantage of its biocompatibility and high strength.

However, the molybdenum wire industry also faces challenges, including fluctuating raw material prices, high production costs, and increased competition in the international market. As a major country in the world’s molybdenum resources, China has unique advantages, but it needs to further improve its independent research and development capabilities of high-end molybdenum wire to cope with the competition from European and American companies (such as Plansee and H.C. Starck). In the future, the research direction of molybdenum wire will focus on the development of nanomaterials, intelligent production and multifunctional composite materials to meet the needs of emerging industries.

READ MORE: Encyclopedia of Molybdenum Wire

===================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com|

Tel: +86 592 5129696 / 86 592 5129595