Directory

Chapter 1: Introduction

1.1 Definition and Overview of Molybdenum Wire EDM

1.2 Wire EDM Technical Background

1.3 The Importance of Molybdenum Wire in EDM

1.4 Significance of Research and Application

Chapter 2: Characteristics of Molybdenum Wire EDM

2.1 Chemical Properties of Molybdenum Wire EDM

2.1.1 Basic Chemical Properties of Molybdenum Element

2.1.2 Purity Requirements

2.1.3 Corrosion Resistance

2.2 Physical Properties of Molybdenum Wire EDM

2.2.1 High Melting Point

2.2.2 Density and Hardness

2.2.3 Electrical and Thermal Conductivity

2.3 Mechanical Characteristics of Molybdenum Wire EDM

2.3.1 Tensile Strength

2.3.2 Elongation

2.3.3 Curvature and Wire Diameter Uniformity

2.4 Geometric Properties of Molybdenum Wire EDM

2.4.1 Wire Diameter Tolerance

2.4.2 Surface Smoothness and Roundness

2.5 Thermophysical Properties of Molybdenum Wire EDM

2.5.1 High Temperature Stability

2.5.2 High Temperature Resistance

2.6 Other Characteristics of Molybdenum Wire EDM

2.6.1 Surface Treatment

2.6.2 Abrasion Resistance and Durability

2.7 MSDS of Molybdenum Wire EDM from CTIA GROUP LTD

Chapter 3: Classifications of Molybdenum Wire EDM

3.1 High-Efficiency Molybdenum Wire for EDM

3.2 High-Precision Molybdenum Wire for EDM

3.3 Molybdenum Wire for HS-EDM

3.4 Molybdenum Wire for MS-EDM

3.5 Special Molybdenum Wire for EDM

Chapter 4: Preparation and Production Process of Molybdenum Wire EDM

4.1 Selection of Raw Materials for Molybdenum Wire EDM

4.1.1 High-Purity Molybdenum Raw Materials

4.1.2 Doping of Rare Earth Elements

4.2 Production Process of Molybdenum Wire EDM

4.2.1 Molybdenum Powder Metallurgy

4.2.2 Sintering and Forging

4.2.3 Rotary Swaging Process

4.2.4 Wire Drawing Process

4.2.5 Surface Treatment of Molybdenum Wire EDM

4.3 Key Technologies of Molybdenum Wire EDM

4.3.1 High-Precision Wire Drawing Die Technology

4.3.2 Temperature Control and Heat Treatment Technology

4.3.3 Doping Process Optimization

4.4 Quality Control of Molybdenum Wire EDM

4.4.1 Wire Diameter Consistency Control

4.4.2 Surface Defect Detection and Treatment

4.4.3 Tensile Strength Test

Chapter 5: Uses of Molybdenum Wire EDM

5.1 Wire EDM Processing

5.1.1 Mould Making

5.1.2 Complex Shape and Microstructure Processing

5.1.3 High-Precision Parts Processing

5.2 Electric Light Source Application

5.2.1 Gates, Hooks, Struts

5.2.2 Core Wire and Heating Wire

5.3 Thermal Spraying

5.3.1 Surface Strengthening and Repair

5.3.2 Preparation of Wear-Resistant Coatings

5.4 Other Industrial Applications

5.4.1 Aerospace Material Processing

5.4.2 Medical Device Manufacturing

5.4.3 Applications in the Electronics Industry

Chapter 6: Production Equipment for Molybdenum Wire EDM

6.1 Raw Material Preparation Equipment

6.1.1 Molybdenum Powder Production Equipment

6.1.2 Sintering Furnaces

6.2 Wire Drawing Equipment

6.2.1 High-Precision Wire Drawing Machine

6.2.2 Gemstone Drawing Dies

6.3 Surface Treatment Equipment

6.3.1 Caustic Washing Equipment

6.3.2 Electrolytic Polishing Equipment

6.3.3 Graphite Emulsion Coating Equipment

6.4 Heat Treatment Equipment

6.4.1 Vacuum Heat Treatment Furnaces

6.4.2 Annealing Furnaces

6.5 Testing and Quality Control Equipment

6.5.1 Wire Diameter Measuring Instrument

6.5.2 Surface Defect Detector

6.5.3 Tensile Strength Testing Machine

Chapter 7: Domestic and Foreign Standards for Molybdenum Wire EDM

7.1 Domestic Standards for Molybdenum Wire EDM

7.1.1 GB/T 4182-2017

7.1.2 GB/T 3462-2017

7.1.3 Other Relevant Industry Standards

7.2 International Standards for Molybdenum Wire EDM

7.2.1 ASTM B387 Standard Specification for Molybdenum and Molybdenum Alloy Rods, Wires, and Plates

7.2.2 ISO 9001 Quality Management System Certification

7.2.3 Other International Standards for Molybdenum Products

7.3 Standard Comparative Analysis of Molybdenum Wire EDM

7.3.1 Differences Between Domestic and Foreign Standards

7.3.2 The Impact of Standards on Product Quality

Chapter 8: Detection Methods of Molybdenum Wire EDM

8.1 Chemical Composition Testing of Molybdenum Wire EDM

8.1.1 Spectral Analysis (ICP-MS)

8.1.2 Molybdenum Purity Testing

8.2 Testing of Physical Properties

8.2.1 Wire Diameter and Tolerance Measurement

8.2.2 Surface Roughness Test

8.3 Testing of Mechanical Properties

8.3.1 Tensile Strength Test

8.3.2 Elongation and Curl Test

8.4 Testing of Thermophysical Properties

8.4.1 High Temperature Stability Test

8.4.2 Electrical and Thermal Conductivity Tests

8.5 Surface Quality Inspection

8.5.1 Microscopic Observation

8.5.2 Non-Destructive Testing Techniques

8.6 Environmental Adaptability Test

8.6.1 Corrosion Resistance Test

8.6.2 High Temperature Oxidation Test

Chapter 9: Optimization and Technical Improvement of Molybdenum Wire EDM

9.1 Methods for Improving Tensile Strength and Durability

9.2 Optimization of Surface Treatment Process

9.3 Techniques to Reduce the Rate of Wire Breakage

9.4 Innovations to Improve Cutting Efficiency

9.5 Application of Intelligent Production Technology

9.5.1 Automatic Wire Drawing Control

9.5.2 Real-Time Quality Monitoring System

Chapter 10: Market and Development of Molybdenum Wire EDM

10.1 Global Market Overview

10.1.1 Major Producing Countries and Regions

10.1.2 Market Size and Demand Analysis

10.2 Development Trends

10.2.1 Research and Development of Thinner Wire Diameters

10.2.2 Environmentally Friendly Production Processes

10.2.3 Substitution of New Materials

Chapter 11: Installation and Use of Molybdenum Wire EDM

11.1 Wire EDM Installation Steps

11.1.1 Molybdenum Wire Threading and Fixing

11.1.2 Contact Control Between the Guide Wheel and Conductive Block

11.2 Precautions for Use

11.2.1 Current and Voltage Parameter Settings

11.2.2 Prevent Wire Breakage and Slippage

11.3 Maintenance and Replacement

11.3.1 Molybdenum Wire Tension Adjustment

11.3.2 Regular Cleaning and Inspection

Chapter 12: Safety and Environmental Protection of Molybdenum Wire EDM

12.1 Safety Measures During Production

12.1.1 Dust and Exhaust Gas Treatment

12.1.2 Equipment Operation Safety Regulations

12.2 Environmental Protection Requirements

12.2.1 Waste Recycling and Disposal

12.2.2 Green Production Technologies

Chapter 13: Common Problems and Solutions of Molybdenum Wire EDM

13.1 Wire Breakage Problems and Treatment Methods

13.2 Solutions to Insufficient Cutting Accuracy

13.3 Surface Quality Issues and Improvement Measures

13.4 Coping Strategies for Excessive Wire Loss

Chapter 14: Future Prospects of Molybdenum Wire EDM

14.1 Potential in High-End Manufacturing

14.2 Challenges from New Materials and Alternative Technologies

14.3 Trends in Intelligence and Automation

Appendix

- Glossary of Terms

- References

Chapter 1 Introduction

1.1 Definition and overview of molybdenum wire EDM

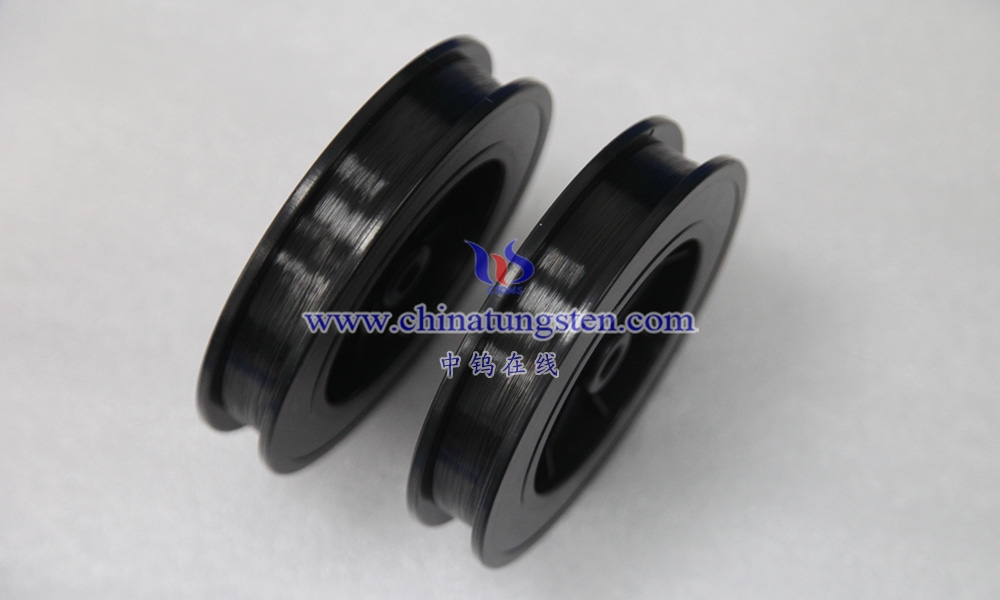

Molybdenum wire EDM is a fine wire made primarily from high-purity molybdenum (with Mo content typically ≥99.3%), and is widely used in Wire Electrical Discharge Machining (WEDM). Due to its high melting point (approximately 2623°C), excellent tensile strength (ranging from 700 to 1200 MPa, depending on the manufacturing process), good electrical conductivity, and high-temperature resistance, molybdenum wire has become a commonly used electrode material in wire-cut EDM. Its diameter generally ranges between 0.08 mm and 0.3 mm, with a tolerance controlled within ±0.001 mm to meet high-precision machining requirements. Surface treatments—such as graphite emulsion coating or alkaline-washed white molybdenum wire—further enhance its discharge performance and durability.

Molybdenum wire is primarily used in fast-wire, medium-speed wire, and some high-precision slow-wire EDM machines. Compared to copper wire, tungsten wire, or brass wire, molybdenum wire offers advantages such as cost-effectiveness, high wear resistance, and suitability for multiple cuts, making it especially dominant in Asian markets like China and Japan. According to the International Molybdenum Association (IMOA), molybdenum is considered a strategic metal, and its demand in industrial applications continues to grow. As a major branch of molybdenum products, the global annual consumption of molybdenum wire EDM is estimated to reach several thousand tons, particularly in the fields of mold manufacturing and precision parts processing.

The production of molybdenum wire involves powder metallurgy, rotary swaging, wire drawing, and surface treatment processes. These steps must ensure uniform wire diameter, smooth surface finish, and optimal mechanical properties to meet the demands of high-speed and high-precision cutting. To further enhance the performance of molybdenum wire, manufacturers are continually innovating, such as developing wires doped with rare earth elements (e.g., lanthanum, yttrium) to improve tensile strength and corrosion resistance.

1.2 Wire EDM Technical Background

Wire EDM (WEDM) is an unconventional processing technology that melts or vaporizes materials at high temperatures (about 8000-12000°C) by using a high-voltage pulse discharge between the electrode wire and the workpiece to achieve precise cutting. This technology originated in the 40s of the 20th century, when the former Soviet scientists Lazarenko and his wife first proposed the principle of electrical discharge machining (EDM). In the 1960s, Swiss and Japanese machine tool manufacturers, such as AgieCharmilles and Fanuc, developed CNC wire EDM machines, which led to the industrial adoption of WEDM.

There are three types of wire EDM technology: fast, medium and slow:

Fast wire: mainly molybdenum wire, high line speed (8-12 m/s), low cost, widely used in mold and part processing in China and other markets, cutting speed up to 100-150 mm²/min, but slightly lower accuracy (surface roughness Ra 2.5-3.2 μm).

Medium wire: Combining the advantages of fast wire and slow wire, molybdenum wire or galvanized wire is used, with higher precision and surface quality (Ra 1.0-1.6 μm) and a cutting speed of about 50-100 mm²/min, which has become rapidly popular in the Chinese market in recent years.

Slow wire: Brass or coated wire (e.g. galvanized copper wire) is usually used, with low wire speed (0.2-0.3 m/s) and extremely high accuracy (Ra 0.2-0.8 μm), which is commonly found in high-end manufacturing in Japan and Europe.

According to the International Association for Manufacturing Technology (AMT), the global wire EDM machine tool market will be worth about $3 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 4.5% by 2030, with China accounting for more than 40% of the global market share. Due to its high-cost performance and applicability, molybdenum wire has become the mainstream choice of fast wire and medium wire equipment, especially in the Asian mold manufacturing and hardware processing industries. The European and North American markets are more inclined to slow wire machines, using copper-based or composite wires, but molybdenum wire is still used in the processing of certain high-strength materials.

Advances in wire EDM technology have benefited from improvements in numerical control technology, pulse power supply and automation control. Modern wire EDM machines are equipped with high-frequency pulse power supplies (up to 1 MHz) and an intelligent tension control system to ensure stable operation of molybdenum wire under high loads and reduce the risk of wire breakage.

1.3 The importance of molybdenum wire in EDM

The importance of molybdenum wire in wire EDM stems from its unique physical and chemical properties, making it ideal for machining high-hardness, complex-shaped materials such as die steel, carbide, titanium alloys. Here are the key advantages of molybdenum wire in WEDM:

High melting point and thermal stability: The high melting point (2623°C) of molybdenum wire allows it to withstand the high temperature generated by discharge, avoid melting or deformation, and ensure stability during the cutting process. Compared with copper wire (melting point 1083°C), molybdenum wire is more durable under high-energy discharge.

Excellent tensile strength: The tensile strength of molybdenum wire (700-1200 MPa) is much higher than that of brass wire (about 400-600 MPa), making it suitable for high-tension operation and reducing the probability of wire breakage, especially when machining thick workpieces (>100 mm).

Cost-effective: The price of molybdenum wire is lower than that of tungsten wire (about 1/3-1/5), and it can be reused (molybdenum wire can be recycled hundreds of times in fast wire equipment), which significantly reduces processing costs. According to Chinese market data, the cost per meter of molybdenum wire is about 0.1-0.3 yuan, while tungsten wire is as high as 1-2 yuan.

Surface treatment adaptability: Molybdenum wire can optimize the surface performance through graphite emulsion coating or alkali washing treatment, enhance discharge efficiency and wear resistance, and adapt to a variety of working conditions of fast wire and medium wire.

Machining complex geometries: The high strength and fine wire diameters (down to 0.08 mm) of molybdenum wire enable the machining of microstructures and complex contours to meet the high precision needs of the aerospace, medical device and electronics industries.

Globally, the application of molybdenum wire in fast wire and medium wire equipment dominates, especially in China’s mold manufacturing industry, where about 80% of wire EDM machine tools use molybdenum wire. According to the IMOA report, molybdenum wire performs well in the machining of die steels (e.g. Cr12MoV), cemented carbide and superalloys, with a cutting accuracy of ±0.005 mm and a surface roughness of Ra 1.0-2.5 μm. In contrast, brass wire, commonly used for slow wire, is more suitable for ultra-high-precision machining (Ra < 0.5 μm), but the cost and frequency of consumables replacement are higher.

Limitations of molybdenum wire include that the conductivity is slightly lower than that of copper-based wire (about 5.5 μΩ·cm for molybdenum and 1.7 μΩ·cm for brass), it may affect discharge efficiency, and it is not as fine as coated wire in extremely high-precision scenarios. However, modern molybdenum wire performance has been significantly improved by doping rare earth elements such as lanthanum or yttrium or optimizing discharge parameters, partially compensating for these shortcomings.

1.4 Significance of research and application

The research and application of molybdenum wire EDM is of great significance to the manufacturing industry, which is reflected in technological progress, industrial upgrading and economic benefits.

Driving high-precision manufacturing: Molybdenum wire EDM supports the processing of complex geometries and high-hardness materials, and is widely used in mold making (stamping molds, injection molds), aerospace (turbine blades, titanium alloy parts), medical devices (orthopedic implants), and electronics (semiconductor molds). Its high precision and stability meet the needs of modern manufacturing for micron-level tolerances. For example, the Japanese Fanuc wire cutting machine uses molybdenum wire processing with an accuracy of ±2 μm, which significantly improves the high-end manufacturing capacity.

Reduced production costs: The high durability and recyclability of molybdenum wire reduces the cost of consumables for wire EDM processing, especially in fast wire machines, where a single molybdenum wire can cut thousands of square meters of workpiece area. The global mold manufacturing market is highly dependent on the cost advantage of molybdenum wire, especially in emerging markets such as China and India.

Promoting technological innovation: The research and development of molybdenum wire drives advances in materials science and manufacturing processes. For example, molybdenum wire doped with rare earth elements (such as La-Mo alloy wire) improves tensile strength and resistance to high-temperature oxidation, extending service life. In addition, intelligent tension control and adaptive discharge technology further optimize the processing efficiency of molybdenum wire.

Supporting green manufacturing: The high recycling rate of waste in molybdenum wire production (up to more than 90%) is in line with the global trend of green manufacturing. Compared with single-use copper-based wire, the recycling of molybdenum wire reduces the waste of resources.

Global Industry Impact: The research and application of molybdenum wire EDM has promoted the regionalization of the global manufacturing industry. As the world’s largest molybdenum resource country (accounting for about 43% of the world’s reserves), China’s molybdenum wire industry has been exported to Southeast Asia, Africa and other places under the “Belt and Road” initiative, which has promoted regional industrial upgrading. Molybdenum wire research in Europe and North America focuses on high-performance doping and surface modification to provide technical support for high-end manufacturing.

In the future, the research directions of molybdenum wire EDM include a thinner wire diameter (<0.05 mm) to support micromachining, composite coating technology to improve discharge efficiency, and intelligent processing systems combined with artificial intelligence. The demand for high-precision, low-cost manufacturing in the global market will continue to drive the development of molybdenum wire technology, especially in the fields of new energy vehicles, 5G equipment and medical devices.

READ MORE: Complete Guide to Molybdenum Wire EDM

===================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

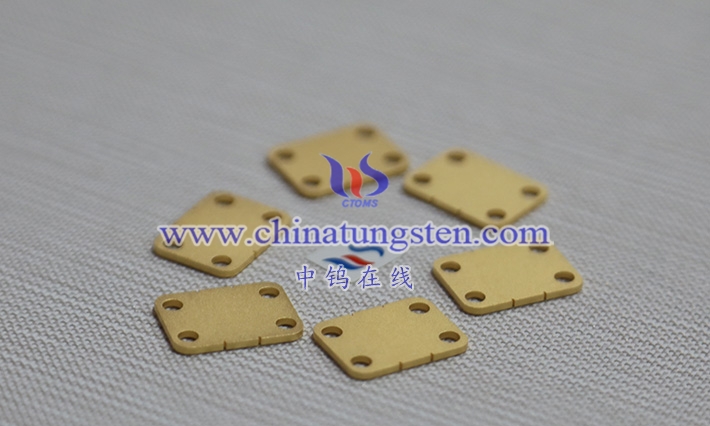

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com|

Tel: +86 592 5129696 / 86 592 5129595