Directory

Chapter 1: Introduction

1.1 Definition and Concept of Molybdenum Spray Wire

1.2 The Historical Evolution of Molybdenum Spray Wire

1.3 Industrial Value and Application Prospect of Molybdenum Spray Wire

1.4 Research and Technical Status of Molybdenum Spray Wire at Home and Abroad

Chapter 2: Characteristics of Molybdenum Spray Wire

2.1 Physical Properties of Molybdenum Spray Wire

2.1.1 Melting Point and Thermal Conductivity

2.1.2 Density and Hardness

2.1.3 Thermal Expansion Coefficient and Thermal Stability

2.1.4 Conductivity and Resistivity

2.2 Chemical Properties of Molybdenum Spray Wire

2.2.1 Corrosion Resistance

2.2.2 Oxidation Resistance

2.2.3 Chemical Inertness and Reactivity

2.3 Mechanical Properties of Molybdenum Spray Wire

2.3.1 Tensile Strength and Yield Strength

2.3.2 Ductility and Fracture Toughness

2.3.3 Wear Resistance and Fatigue Properties

2.4 Spray Coating Performance

2.4.1 Coating Adhesion and Bond Strength

2.4.2 Coating Porosity and Uniformity

2.4.3 Coating Resistance to High Temperature and Thermal Shock

2.4.4 Surface Roughness and Microstructure of Coatings

2.5 Molybdenum Spray Wire MSDS from CTIA GROUP LTD

Chapter 3: Preparation and Production Process of Molybdenum Spray Wire

3.1 Preparation of Raw Materials

3.1.1 Molybdenum Ore Beneficiation and Purification Technology

3.1.2 Production Process of High-Purity Molybdenum Powder

3.1.3 Quality Control and Testing of Molybdenum Powder

3.2 Molybdenum Wire Forming Process

3.2.1 Powder Metallurgy Molding Technology

3.2.2 Molybdenum Wire Drawing Process

3.2.2.1 Single-Die Wire Drawing

3.2.2.2 Multi-Mode Continuous Wire Drawing

3.2.3 Molybdenum Wire Annealing and Stress Relief

3.2.4 Surface Cleaning and Polishing

3.3 Special Processing for Molybdenum Spray Wire

3.3.1 Surface Activation Treatment

3.3.2 Specification Customization

3.3.3 Surface Modification Technology

3.4 Spraying Process

3.4.1 Surface Pretreatment of Substrates

3.4.1.1 Mechanical Sandblasting

3.4.1.2 Chemical Cleaning

3.4.1.3 Ultrasonic Cleaning

3.4.2 Thermal Spray Technology

3.4.2.1 Flame Spraying Process

3.4.2.2 Plasma Spraying Process

3.4.2.3 Arc Spraying Process

3.4.2.4 High Velocity Oxy-Fuel Spraying (HVOF)

3.4.3 Post-Spraying Treatment

3.4.3.1 Heat Treatment and Annealing

3.4.3.2 Coating Polishing and Finishing

3.4.3.3 Coating Sealing Treatment

3.5 Optimization of Production Process

3.5.1 Optimization and Control of Process Parameters

3.5.2 Quality Assurance System

3.5.3 Green Manufacturing and Energy-Saving Technologies

3.6 Key Technical Points

3.6.1 Preparation Technology of High-Purity Molybdenum Wire

3.6.2 Spray Coating Quality Control

3.6.3 Spraying Efficiency and Consistency

3.7 Application of Advanced Technology

3.7.1 Nanometer Spraying Technology

3.7.2 Laser-Assisted Spraying Technology

3.7.3 Cold Spray Technology

3.7.4 Intelligent and Automated Spraying System

3.8 Technical Challenges and Solutions

3.8.1 Coating Peeling and Cracking

3.8.2 High-Temperature Oxidation and Performance Degradation

3.8.3 Balance Between Production Cost and Efficiency

3.8.4 Adaptability to Spraying Complex Substrates

Chapter 4: Classification of Molybdenum Spray Wire

4.1 Classification by Purity

4.1.1 High-Purity Molybdenum Wire

4.1.2 Doped Molybdenum Wire

4.2 Classification by Use

4.2.1 For Industrial Spraying

4.2.2 For Functional Coating

4.3 Classification According to Spraying Process

4.3.1 For Flame Spraying

4.3.2 For Arc Spraying

4.3.3 For Plasma Spraying

4.3.4 For High-Velocity Oxy-Fuel Spraying (HVOF)

4.3.5 For Cold Spraying

Chapter 5: Uses of Molybdenum Spray Wire

5.1 Aerospace Field

5.1.1 Turbine Blades and Engine Components

5.1.2 High-Temperature Structural Parts and Thermal Barrier Coatings

5.1.3 Wear-Resistant and Anti-Corrosion Coating for Spacecraft

5.2 Automotive Industry

5.2.1 Engine Piston and Block Coating

5.2.2 High Temperature Resistant Coating for Exhaust System

5.2.3 Wear-Resistant Coating for Brake System

5.3 Chemical and Energy Industries

5.3.1 Corrosion-Resistant Pipes and Valves

5.3.2 Reactor and Heat Exchanger Coatings

5.3.3 Coatings for Solar and Wind Energy Equipment

5.4 Electronics and Semiconductor Industry

5.4.1 Heating Wire for Vacuum Coating

5.4.2 Semiconductor Leads and Electrodes

5.4.3 Thin Film Deposition Coating

5.5 Medical and Bioengineering

5.5.1 Heating Elements for Medical Devices

5.5.2 Corrosion-Resistant Coatings for Medical Devices

5.6 Other Areas of Application

5.6.1 Anti-Corrosion Coatings for Ships and Offshore Engineering

5.6.2 Wear-Resistant Coatings for Construction Machinery

5.6.3 High-Temperature Stoves and Heat Treatment Equipment

Chapter 6: Production Equipment for Molybdenum Spray Wire

6.1 Raw Material Processing Equipment

6.1.1 Molybdenum Powder Preparation and Reduction Equipment

6.1.2 Sintering Furnaces and Forging Equipment

6.2 Molybdenum Wire Production Equipment

6.2.1 Wire Drawing Machines and Dies

6.2.2 Annealing Furnaces and Heat Treatment Equipment

6.2.3 Surface Cleaning and Polishing Equipment

6.3 Spraying Equipment

6.3.1 Flame Spraying Systems

6.3.2 Plasma Spraying Equipment

6.3.3 Arc Spraying Device

6.3.4 High-Velocity Oxy-Fuel Spraying (HVOF) Equipment

6.4 Auxiliary and Post-Treatment Equipment

6.4.1 Substrate Pretreatment Equipment

6.4.2 Coating Post-Treatment Equipment

6.4.3 Online Detection and Monitoring Equipment

6.5 Automation and Intelligent Equipment

6.5.1 Automatic Spraying Production Line

6.5.2 Intelligent Control and Data Acquisition Systems

6.5.3 Robotic Spraying Systems

Chapter 7: Domestic and Foreign Standards for Molybdenum Spray Wire

7.1 Domestic Standards

7.1.1 GB/T 4181-2017 “Molybdenum Wire” and Related Requirements

7.1.2 GB/T 3462-2017

7.1.3 GB/T 4197-2011

7.1.4 Other Relevant National Standards

7.2 International Standards

7.2.1 ASTM B387-18

7.2.2 ISO 20407 Specification for Thermal Spray Materials

7.2.3 ISO 14919 Wire for Thermal Spraying

7.2.4 Other International Standards

7.3 Industry Standards and Enterprise Specifications

7.3.1 Non-Ferrous Metal Industry Standards

7.3.2 Thermal Spraying Industry Standards

7.3.3 Internal Quality Control Specifications

7.4 Standard Comparison and Applicability Analysis

7.4.1 Differences in Domestic and Foreign Standards

7.4.2 Standard Application Scenarios and Selection

Chapter 8: Testing and Quality Control of Molybdenum Spray Wire

8.1 Raw Material Testing

8.1.1 Chemical Composition Analysis

8.1.2 Particle Size and Morphology Detection

8.1.3 Impurity Content Detection

8.2 Quality Inspection of Molybdenum Wire

8.2.1 Dimensional Accuracy and Tolerance

8.2.2 Surface Defect and Roughness Detection

8.2.3 Mechanical Properties Testing

8.3 Spray Coating Inspection

8.3.1 Coating Thickness and Uniformity

8.3.2 Coating Adhesion Test

8.3.3 Microstructure and Porosity Analysis

8.3.4 Corrosion and High Temperature Resistance

8.3.5 Thermal Shock Performance

8.4 Testing Technology and Equipment

8.4.1 X-Ray Fluorescence (XRF)

8.4.2 SEM and EDS Analysis

8.4.3 Hardness Testing (Vickers, Rockwell)

8.4.4 Ultrasonic and Laser Thickness Testing

8.4.5 Other Advanced Detection Technologies

8.5 Quality Management System

8.5.1 ISO 9001 Certification

8.5.2 Test Reports and Traceability

8.5.3 Defect Analysis and Improvement

Chapter 9: Development Trend and Future Prospect

9.1 Technical Development Trend

9.1.1 New Spraying Materials and Processes

9.1.2 Intelligent and Digital Production

9.1.3 Composite Coating Technology

9.2 Market Demand and Application Expansion

9.2.1 Potential in Emerging Industries

9.2.2 Global Market Trend Analysis

9.3 Environmental Protection and Sustainability

9.3.1 Green Spraying Technology

9.3.2 Waste Recovery and Recycling

9.4 International Technical Exchange and Cooperation

9.4.1 Harmonization of International Standards

9.4.2 Cross-Border R&D and Collaboration

Appendix

- Glossary of Terms

- References

Chapter 1 Introduction

1.1 Definition and concept of molybdenum spray wire

1.1.1 Basic definition of molybdenum spray wire

Molybdenum spray wire is a metal wire material specifically used in the thermal spray process, usually made of high-purity molybdenum (Molybdenum, chemical symbol Mo, atomic number 42). Molybdenum is a transition metal with properties such as high melting point (about 2623°C), high strength, corrosion resistance and excellent thermal conductivity, which makes it one of the important materials in the field of thermal spraying. Thermal spraying is a surface engineering technique that creates a layer of coating with a specific function by spraying molten or semi-melted material onto the surface of a substrate at high velocity. As a raw material for thermal spraying, molybdenum spray wire is usually used in the form of arc spraying or flame spraying, and its main purpose is to form a layer of wear-resistant, high-temperature or corrosion-resistant molybdenum coating on the surface of the substrate.

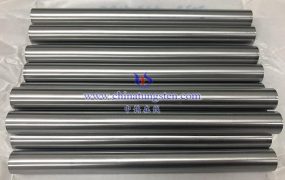

The typical form of molybdenum spray wire is a slender metal wire, usually between 1.0mm and 3.2mm in diameter, depending on the spraying equipment and process requirements. The molybdenum wire is heated to a molten or semi-molten state by a spray gun during the spraying process, and then accelerated by a compressed gas (such as nitrogen or air) onto the target substrate to form a uniform coating. Such coatings typically have high hardness, low coefficient of friction and good bond strength, which can significantly improve the surface properties of the substrate.

1.1.2 Physical and chemical properties of molybdenum

Molybdenum’s unique physical and chemical properties are the basis for its use as a coating material. Molybdenum has a density of 10.28 g/cm³, which is lower than tungsten (19.25 g/cm³) but higher than many common metals, which allows molybdenum coatings to achieve a good balance between weight and performance. Molybdenum has a high melting point of 2623°C, second only to tungsten and rhenium, which allows it to maintain structural stability and mechanical strength at high temperatures. In addition, molybdenum is more resistant to acids, alkalis, and certain corrosive gases than many other metals, especially in non-oxidizing environments.

Molybdenum has a low coefficient of thermal expansion (about 4.8×10⁻⁶/K), which means that in environments with drastic temperature changes, there is less thermal stress between the molybdenum coating and the substrate, reducing the risk of cracking or peeling of the coating. Molybdenum also has good electrical and thermal conductivity (thermal conductivity of about 138 W/m·K), which makes the coating formed by molybdenum spray wire advantageous in applications where thermal or electrical conductivity is required. In addition, molybdenum is self-lubricating under certain conditions, especially at high temperatures or in a vacuum, which further expands its application scenarios.

1.1.3 Preparation process of molybdenum spray wire

The preparation of molybdenum spray wire requires multiple processes to ensure its high purity and consistent physical properties. Molybdenum wire is usually prepared by powder metallurgy technology, and the specific steps include:

Molybdenum concentrate extraction: Molybdenum concentrate is extracted from molybdenum ore (such as molybdenite) to remove impurities through flotation and chemical purification.

Molybdenum powder production: molybdenum concentrate is roasted to produce molybdenum oxide (MoO₃), and then high-purity molybdenum powder is obtained by hydrogen reduction.

Molybdenum billet forming: Molybdenum powder is pressed into a rod or plate blank and sintered at high temperatures to increase density.

Wire drawing: Through hot forging, rolling and multiple wire drawing processes, the molybdenum billet is processed into filaments to achieve the diameter and surface finish required for spraying.

Surface treatment: Molybdenum wire is cleaned, annealed or doped to optimize its mechanical properties and spraying effect.

The purity of molybdenum wire is usually required to reach more than 99.95% to ensure the quality of the spray coating. Some molybdenum spray wires may be doped with small amounts of elements (such as lanthanum, cerium, or potassium) to improve their resistance to high-temperature oxidation or ductility.

1.1.4 The role of molybdenum spray wire in thermal spraying

In the thermal spraying process, the molybdenum wire is fed into the spraying gun by arc spraying or flame spraying equipment, and when heated, it forms molten droplets or semi-molten particles. These particles hit the surface of the substrate under the action of high-velocity air currents, quickly cool and solidify, forming a dense coating. The main functions of molybdenum coating include:

Wear protection: The high hardness of the molybdenum coating (approx. 5.5 on the Mohs scale) makes it effective against mechanical wear.

High Temperature Protection: Molybdenum’s high melting point makes it suitable for use in components in high temperature environments, such as aero engine turbine blades.

Corrosion Protection: Molybdenum’s corrosion resistance to certain chemicals makes it suitable for use in chemical equipment or marine environments.

Self-lubricating properties: Molybdenum coatings can form molybdenum oxide (MoO₃) at high temperatures or in vacuum environments, and have a low coefficient of friction, making them suitable for use in sliding parts.

1.1.5 Comparison of molybdenum spray wire with other spraying materials

Compared to common spray materials such as nickel-based alloys, tungsten or ceramics, molybdenum spray wire offers the following advantages:

Cost-effective: Molybdenum costs less than tungsten and some precious metals, but has similar performance and is suitable for large-scale industrial applications.

Versatility: Molybdenum coatings are resistant to abrasion, high temperatures, and corrosion, and are suitable for a wide range of applications.

Ease of processing: The ductility of molybdenum wire makes it easy to draw into different specifications and adapt to a variety of spraying equipment.

However, molybdenum is prone to the formation of volatile oxides (MoO₃) in oxidizing atmospheres, which limits its application in some high-temperature oxidizing environments. In contrast, ceramic coatings may be better in terms of oxidation resistance, but they are more brittle and do not have as strong binding strength as molybdenum coatings.

1.1.6 Specifications and classification of molybdenum spray wire

Molybdenum spray wire can be divided into a variety of specifications according to the use and process requirements, and the common classifications include:

Pure molybdenum wire: ≥ 99.95% purity, used in standard spraying processes.

Doped molybdenum wire: Doped with elements such as lanthanum (La), cerium (Ce) or potassium (K) to improve oxidation resistance or ductility.

Diameter classification: Common diameters include 1.0mm, 1.6mm, 2.0mm, 3.2mm, etc., which are suitable for different spraying equipment.

Surface treatment classification: such as black molybdenum wire (uncleaned, with an oxide layer on the surface) and white molybdenum wire (bright surface after cleaning).

These classifications enable molybdenum spray wire to meet the needs of different industrial applications, such as aerospace, automotive manufacturing, and energy equipment.

1.2 The historical evolution of molybdenum spray wire

1.2.1 Discovery and early application of molybdenum

The discovery of molybdenum dates back to the 18th century. In 1778, the Swedish chemist Carl Wilhelm Scheele first isolated molybdenum oxide from molybdenite and named it “molybdenum” (derived from the Greek word “molybdos”, meaning a lead-like substance). In 1781, the Swedish chemist Peter Jacob Hjelm prepared molybdenum metal for the first time by carbon reduction, laying the foundation for the industrial application of molybdenum.

At the end of the 19th century, molybdenum began to be used as an alloying element in the steel industry to improve the strength and corrosion resistance of steel. However, due to the limitations of molybdenum purification and processing technology, its application scope is relatively narrow, mainly limited to the metallurgical field. Until the beginning of the 20th century, with the progress of powder metallurgy and wire drawing technology, the preparation of molybdenum wire became possible, providing conditions for its application in the field of spraying.

1.2.2 Origin of thermal spray technology

Thermal spray technology originated in the early 20th century. In 1910, Swiss engineer Max Ulrich Schoop invented the flame spraying technique, which melted and sprayed metal powder or wire onto the surface of the substrate by burning combustible gas. The emergence of this technology provides the possibility for the application of molybdenum spray wire. In the 1920s, arc spraying technology was introduced, which used an electric arc to heat wire to generate molten droplets, further improving spraying efficiency and coating quality.

Early thermal spraying mainly used meltable metals, such as zinc and aluminum, for anti-corrosion coatings. As a metal with a high melting point, the application of molybdenum in thermal spraying started late, and it was not until the middle of the 20th century, with the development of superalloys and aerospace industry, that the spraying application of molybdenum wire gradually attracted attention.

1.2.3 Early development of molybdenum spray wire

In the 50s of the 20th century, molybdenum spray wire began to emerge in the industrial field. The aerospace industry in the U.S. pioneered the application of molybdenum coatings to turbine blades and combustion chamber components to combat high temperatures and wear issues. Molybdenum’s high melting point and wear resistance make it an ideal coating material, especially in gas turbines and jet engines. At the same time, industry in Europe and Japan began to explore the application of molybdenum wire spraying in machine building, such as wear-resistant coatings for piston rings and bearings.

During this period, the preparation technology of molybdenum spray wire was still relatively rough, and the purity and surface quality of molybdenum wire were unstable, resulting in large fluctuations in coating properties. In the 1960s, with advances in vacuum melting and hydrogen reduction technology, the purity of molybdenum wire was significantly improved, and the bonding strength and durability of spray coatings were improved.

1.2.4 Development of modern molybdenum spray wire technology

After the 70s of the 20th century, thermal spraying technology entered a stage of rapid development. The advent of plasma spraying and high-velocity flame spraying (HVOF) has significantly improved the quality of spray coatings, allowing molybdenum coatings to be used in more demanding environments. For example, high-velocity flame spraying can create a denser molybdenum coating, reduce porosity, and improve the bonding strength of the coating to the substrate.

During the same period, a breakthrough was made in the doping technology of molybdenum wire. Molybdenum wire doped with lanthanum or cerium exhibits better oxidation resistance and ductility in high temperature environments, expanding the application field of molybdenum spray wire. In the 1980s, molybdenum spray wire began to be widely used in the automotive industry to make wear-resistant piston rings and synchronizer rings, significantly extending the service life of parts.

1.2.5 The development of molybdenum spray wire in China

China’s molybdenum industry started late, but it is developing rapidly. In the 60s of the 20th century, China began to extract molybdenum from molybdenite and gradually established molybdenum wire production capacity. In the 1980s, with the advancement of reform and opening up and industrial modernization, China’s molybdenum products enterprises began to introduce foreign advanced wire drawing and spraying equipment, and the production and application of molybdenum spray wire entered a period of rapid development.

In the 1990s, China became the world’s largest producer of molybdenum, and the production technology of molybdenum wire gradually matured. Through technological innovation, China’s major molybdenum products enterprises have developed high-purity molybdenum wire and doped molybdenum wire to meet the needs of the domestic and foreign spraying markets. After 2000, China’s molybdenum spray wire began to be exported to Europe, America and Southeast Asian markets, becoming an important part of the global molybdenum product supply chain.

1.2.6 Milestones in the coating of molybdenum wire

1910: Thermal spraying technology was invented, laying the foundation for the application of molybdenum spray wire.

1950s: Molybdenum wire spraying is first used in the aerospace sector.

1970s: Plasma spraying and high-velocity flame spraying technologies drive improved molybdenum coating performance.

1980s: Development of doped molybdenum wire to improve the oxidation resistance of coatings.

After 2000, China became an important base for global molybdenum wire production and spraying technology.

1.3 Industrial value and application prospect of molybdenum spray wire

1.3.1 Industrial value of molybdenum spray wire

As the core material in thermal spraying technology, the industrial value of molybdenum spray wire is reflected in its unique physical and chemical properties, a wide range of application scenarios, and its contribution to the efficiency and sustainability of modern industry. Molybdenum’s high melting point, high hardness, corrosion resistance and self-lubricating properties make it irreplaceable in the field of surface engineering. The following is a detailed analysis of its industrial value from multiple dimensions.

1.3.1.1 Improve the durability and life of components

The coating formed by molybdenum spray wire significantly extends the service life of mechanical components with its high hardness (about 5.5-6.0 on the Mohs scale) and wear resistance. For example, in the automotive industry, piston rings and synchronizer rings are critical components in engines and transmissions that are subjected to high-frequency friction and high-temperature environments for long periods of time. While conventional uncoated piston rings can wear out for thousands of hours under high loads, molybdenum-coated piston rings can extend their life by a factor of 2-3, with some cases showing a service life of more than 100,000 km. This increased durability directly reduces maintenance costs and equipment downtime.

In addition, the stability of molybdenum coatings in high-temperature environments makes them of great value in the aerospace industry. For example, the turbine blades of gas turbines operate in combustion environments in excess of 1000°C, and molybdenum coatings are effective in resisting thermal fatigue and wear, extending blade life. According to industry data, the maintenance interval of molybdenum-coated turbine blades can be extended by 20%-30%, significantly reducing the full life cycle cost of aero engines.

1.3.1.2 Improve the efficiency of equipment operation

The low coefficient of friction (as low as 0.1-0.2 under certain conditions) of molybdenum coatings makes them self-lubricating, which can significantly reduce frictional losses in mechanical components and thus improve the operating efficiency of equipment. In the automotive industry, the application of molybdenum-coated piston rings can reduce the frictional power consumption inside the engine and improve fuel efficiency by about 1%-2%. Based on the global annual output of 80 million vehicles, if 10% of the engine uses molybdenum-coated piston rings, millions of tons of fuel can be saved every year, and the economic and environmental benefits are significant.

In the aerospace sector, molybdenum coatings are used in the combustion chambers and nozzles of jet engines to reduce material loss at high temperatures and ensure stable thrust. Studies have shown that the thermal efficiency of molybdenum-coated combustion chambers can be improved by about 0.5%, which is important in the aerospace sector, as even small efficiency gains can significantly reduce fuel consumption and operating costs.

1.3.1.3 Reduce production and maintenance costs

Compared with high melting point metal or ceramic coatings such as tungsten and rhenium, molybdenum has a higher cost performance. The global reserves of molybdenum are relatively abundant (about 25 million tons, of which China accounts for more than 50%), and the purification and processing costs are lower than that of tungsten (about 1/2-1/3). The cost of molybdenum spray wire is about $50-$100 per kilogram, while the cost of tungsten wire can reach more than $200. This makes molybdenum coatings more economically advantageous for large-scale industrial applications.

In addition, the restorative properties of molybdenum coatings are one of its important values. Worn molybdenum coatings can be repaired by re-spraying without replacing the entire part. For example, in the bearing repair of heavy machinery, the application of molybdenum coating can reduce repair costs by more than 50% while reducing downtime. This restorative nature is particularly important in the mining, steel, and energy industries, where large equipment replacements are costly and time-consuming.

1.3.1.4 Meet the requirements of environmental protection and sustainable development

Molybdenum is a non-toxic and environmentally friendly metal material that meets the requirements of the EU RoHS directive and REACH regulations. Compared with traditional lead-based or cadmium-based coatings, molybdenum coatings do not release harmful substances during production and use, and are harmless to the environment and human health. In addition, the durability of the molybdenum coating reduces the frequency of parts replacement, thereby reducing resource consumption and waste generation, in line with the concept of green manufacturing.

In terms of energy efficiency, the self-lubricating properties of molybdenum coatings reduce the use of lubricating oils. For example, in automotive engines, molybdenum-coated piston rings can reduce lubricant consumption by about 10 percent, reducing waste oil disposal costs. This is of great significance for the global promotion of a low-carbon economy and a circular economy.

1.3.1.5 Promote industrial intelligence and efficiency

With the advancement of Industry 4.0, the demand for high-performance materials for smart manufacturing is increasing. The precise processing and coating uniformity of the molybdenum spray wire enables it to meet the requirements of precision manufacturing. For example, in robotic joints and high-speed cutting tools, molybdenum coatings can reduce friction and heat accumulation, improving motion accuracy and tool life. Studies have shown that the life of molybdenum-coated cutting tools can be extended by 30%-50%, which has significant advantages in automated production lines.

In addition, the conductivity of the molybdenum coating (resistivity about 5.5×10⁻⁸ Ω·m) and thermal conductivity (approx. 138 W/m·K) make it unique in electronic and energy devices. For example, in semiconductor manufacturing equipment, molybdenum coatings can be used for electrodes and thermally conductive components to improve the stability and heat dissipation efficiency of the equipment.

1.3.2 Main application areas

The coating of molybdenum spray wire is widely used in many industrial fields due to its versatility, and the following is a detailed analysis of its main application scenarios:

1.3.2.1 Aerospace

Aerospace is one of the most important application areas for molybdenum spray wire. Molybdenum coatings are mainly used for high-temperature components such as turbine blades, combustion chambers, nozzles, and guide vanes. For example, in the turbofan engines of the Boeing 737 and Airbus A320, molybdenum coatings are used to protect turbine blades from wear and maintain stable performance above 1200°C. The coefficient of thermal expansion of the molybdenum coating (about 4.8×10⁻⁶/K) is close to that of nickel-based superalloys, reducing coating spalling caused by thermal stress.

In addition, molybdenum coatings are also used in spacecraft thermal protection systems. For example, some parts of SpaceX’s Starship are coated with molybdenum to withstand the extreme heat during re-entry. Studies have shown that the self-lubricating properties of molybdenum coatings in a vacuum environment make them particularly suitable for sliding parts of spacecraft, such as satellite antenna drive mechanisms.

1.3.2.2 Automotive industry

The automotive industry is one of the largest markets for molybdenum spray wire, with about 30% of the world’s molybdenum spray wire used in the manufacture of automotive parts. Molybdenum coatings are mainly used in components such as piston rings, synchronizer rings, crankshafts and valves. For example, the Volkswagen Group has made extensive use of molybdenum-coated piston rings in its TSI engines to improve fuel efficiency and durability. The data shows that molybdenum-coated piston rings can reduce friction losses by about 15%, significantly improving engine performance.

In addition, molybdenum coating also has potential in the field of new energy vehicles. For example, motor bearings and transmission gears in electric vehicles can be coated with molybdenum to improve wear resistance and thermal conductivity and extend service life. It is estimated that by 2030, the global production of new energy vehicles will exceed 30 million, and the market demand for molybdenum coating will further grow.

1.3.2.3 Energy equipment

In the energy sector, molybdenum coatings are widely used in boilers, heat exchangers, gas turbines, and nuclear power equipment. For example, in the boiler pipes of coal-fired power plants, molybdenum coatings are able to resist high-temperature corrosion and abrasion, extending the life of the pipes by about 2 times. In nuclear power, molybdenum coatings are used in the radiation shielding components of reactors and are effective in absorbing neutron radiation due to their high density (10.28 g/cm³) and non-toxicity.

Renewable energy equipment is also an important application area for molybdenum coatings. For example, the molybdenum coating on the gear surface of the wind turbine gearbox reduces wear and lubrication and reduces maintenance costs. As the global installed wind power capacity exceeds 1,000 GW by 2024, the demand for molybdenum coatings in wind power equipment continues to grow.

1.3.2.4 Machinery manufacturing

In mechanical engineering, molybdenum coatings are used for surface protection of bearings, gears, molds and cutting tools. For example, in mining equipment, molybdenum-coated drill bits can extend the service life by more than 50% and reduce the frequency of equipment replacement. In injection molds, molybdenum coating can reduce the adhesion of molds to plastics, improve mold release efficiency and product surface quality.

1.3.2.5 Chemical and marine engineering

The corrosion resistance of molybdenum coatings makes it widely used in chemical equipment and offshore engineering. For example, in petrochemical reactors, molybdenum coatings are resistant to acid gases and high-temperature corrosion, extending equipment life. In offshore platforms and marine equipment, molybdenum coatings protect steel structures from seawater corrosion and are particularly suitable for use in pipes and valves on deep-sea drilling platforms.

1.3.2.6 Medical and electronics industries

In the medical field, molybdenum coatings are used in radiation shielding components of X-ray equipment and CT machines due to their non-toxicity and high density. For example, in CT scanners from Siemens Healthineers, molybdenum coatings are used to shield against radiation and ensure image quality and patient safety. In the electronics industry, molybdenum coatings are used in the thermal and electrically conductive parts of semiconductor manufacturing equipment, such as the electrodes of plasma etching machines, and their thermal conductivity can improve the heat dissipation efficiency of the equipment by about 20%.

1.3.3 Application Prospects and Market Trends

1.3.3.1 Potential in the field of new energy

With the global energy transition, the demand for high-performance coatings for new energy equipment is growing rapidly. Molybdenum coatings have a promising future in wind, nuclear power and solar equipment. For example, molybdenum coating on the gear surface of wind turbine gearboxes reduces wear and improves transmission efficiency. In the field of nuclear power, molybdenum coatings can be used in the fuel rod shells of Generation IV nuclear reactors to resist high temperatures and radiation damage. It is estimated that by 2030, the global new energy equipment market will exceed 1.5 trillion US dollars, and the demand for molybdenum coating will grow at an average annual rate of 6%.

1.3.3.2 Smart Manufacturing and Industry 4.0

Industry 4.0 emphasizes intelligence, automation and high efficiency, and the application prospect of molybdenum coating in precision manufacturing is significant. For example, in robot joints, molybdenum coatings reduce friction and heat accumulation, improving motion accuracy and longevity. In 3D printing equipment, molybdenum-coated nozzles are able to resist the wear and tear of high-temperature molten materials and extend their service life. The global smart manufacturing market is expected to reach $500 billion by 2028, and molybdenum coatings will benefit as a key material.

1.3.3.3 Marine engineering and green ships

There is an increasing demand for corrosion-resistant coatings in offshore engineering. Molybdenum coatings are widely used in deep-sea drilling platforms, offshore wind power equipment and green ships. For example, molybdenum coatings can be used to protect the surface of ship propellers, reduce seawater corrosion and biological adhesion, and improve propulsion efficiency. The global offshore market is expected to reach $200 billion by 2030, and molybdenum coatings will be an important solution.

1.3.3.4 Medical and biotechnology

The non-toxicity and biocompatibility of molybdenum coatings give them potential in medical devices. For example, in orthopedic implants, molybdenum coatings can improve the wear and corrosion resistance of the implants and extend their service life. In addition, the use of molybdenum coatings in dental tools and surgical instruments is gradually increasing. The global medical device market is expected to reach $600 billion by 2027, and the demand for molybdenum coatings will continue to grow.

1.3.3.5 Market size and economic benefits

According to industry data, the global molybdenum market size will be about $5 billion in 2024, of which molybdenum spray wire accounts for about 10% of the share. It is expected that by 2030, the molybdenum spray wire market will grow at an average annual rate of 5.5% to reach $800 million. As the world’s largest molybdenum producer, China accounts for more than 50% of the global output, and many Chinese companies have become important suppliers of the global molybdenum spray wire market through technological innovation and large-scale production.

1.3.4 Case Study

1.3.4.1 Aerospace case: GE Aviation

General Electric (GE) Aviation makes extensive use of molybdenum coatings in its GEnx engines for wear protection of turbine blades. GEnx engines are used in the Boeing 787 Dreamliner, and the molybdenum coating keeps the turbine blades stable in high-temperature and high-pressure environments, extending maintenance intervals by 25 percent. This application saves GE Aviation hundreds of millions of dollars in maintenance costs each year.

1.3.4.2 Case for the automotive industry: Volkswagen

Volkswagen uses molybdenum-coated piston rings in its 1.4L TSI engine, which significantly improves fuel efficiency and durability. Tests have shown that molybdenum-coated piston rings reduce friction losses by 15% and extend engine life to more than 150,000 km. This technology has been rolled out to several Volkswagen Group models, with annual production of more than 5 million units worldwide.

1.3.4.3 Energy equipment case: Siemens wind power

Siemens Gamesa uses a molybdenum coating in its offshore wind gearboxes to reduce gear wear and lubricant usage. Tests have shown a 40% longer life and a 30% reduction in maintenance costs for molybdenum-coated gears. This technology has been applied to several offshore wind projects around the world.

1.4 Research and technical status of molybdenum spray wire at home and abroad

1.4.1 Current status of domestic research

As the world’s largest molybdenum producer (about 150,000 tons in 2024, accounting for 50% of the world’s total), China has significant advantages in the research and development and application of molybdenum spray wire. Domestic research institutions and enterprises have made important progress in the preparation of molybdenum wire, the optimization of spraying process and the improvement of coating performance. The following is a detailed analysis of the current state of research in China:

1.4.1.1 Major research institutions

Institute of Metal Research, Chinese Academy of Sciences: The surface engineering team of the institute focuses on the research of molybdenum-based coatings, and has developed a molybdenum wire preparation technology doped with lanthanum (La) and cerium (Ce). The results show that the oxidation resistance of molybdenum wire doped with 1% lanthanum is increased by 30% and the coating life is extended by 50% in an oxidizing atmosphere at 1000°C. In addition, the institute studied the microstructure of molybdenum coatings and improved the hardness and bonding strength of the coatings by controlling the grain size (10-50nm).

University of Science and Technology Beijing: The School of Materials Science and Engineering at the same university has studied the effects of plasma spraying and high-velocity flame spraying (HVOF) technology on the performance of molybdenum coatings. The experimental results show that the porosity of the molybdenum coating formed by the HVOF process is reduced to less than 1%, and the binding strength reaches 80 MPa, which is significantly better than that of the traditional arc spraying (porosity is about 5%, and the binding strength is about 50 MPa).

Tsinghua University: The Department of Materials at Tsinghua University has developed a cold spray technology for the preparation of molybdenum coatings, which form high-density coatings through ultra-high-velocity particle impact, reducing thermal stress and oxide formation. Cold-spray molybdenum coatings are available up to HV800 hardness for high-precision component applications.

1.4.1.2 Major Enterprises

CTIA GROUP LTD.: As a leading molybdenum products company in China, Chinatungsten Online focuses on the production of high-purity molybdenum wire (purity ≥99.95%), providing molybdenum spray wire with a diameter of 1.0-3.2mm.

1.4.1.3 Research focus

Doping technology: Doping rare earth elements or alkali metals (such as potassium) to improve the high temperature oxidation resistance and mechanical properties of molybdenum wire. For example, molybdenum wire doped with 0.8% cerium reduces the oxidation rate by 40% at 1200°C.

Spraying process optimization: Plasma spraying and HVOF process parameter optimization, such as spraying distance (100-150mm), gas flow rate (50-80 L/min) and current intensity (400-600 A), are studied to reduce coating porosity and improve bonding strength.

Green manufacturing: Develop low-energy spraying equipment and environmentally friendly molybdenum coating process to reduce exhaust emissions and energy consumption in the spraying process. For example, the use of nitrogen instead of argon as a spray gas can reduce costs by about 15%.

1.4.1.4 Application Cases

High-speed rail braking system: CRRC’s EMU brake disc adopts molybdenum coating, which improves wear resistance and high temperature resistance by 50%, and extends the life of the brake disc to 10 years.

Petrochemical equipment: Sinopec applied molybdenum coating to the pipeline of the catalytic cracking unit to resist acid gas corrosion, and the pipeline life was extended by 3 times.

1.4.2 Current status of foreign research

The research and application of molybdenum spray wire in foreign countries started earlier, especially in the United States, Germany and Japan, and the related technology is in the leading position in the world. The following is a detailed analysis of the current state of research abroad:

1.4.2.1 Major research institutions and enterprises

Praxair, USA: Praxair, a global leader in thermal spray technology, has developed a plasma spray system capable of producing molybdenum coatings with a porosity of less than 0.5% and a bond strength of up to 100 MPa. The company has investigated molybdenum-based composite coatings to improve the hardness and wear resistance of the coating by adding ceramic particles such as Al₂O₃.

Höganäs, Germany: Höganäs focuses on the development of molybdenum-based composite coatings, researching a hybrid spraying process of molybdenum and nickel-based alloys to form coatings that are both wear-resistant and corrosion-resistant. Its products are widely used in the automotive and energy equipment markets in Europe.

Toshiba of Japan: Toshiba has studied the high-temperature oxidation resistance of molybdenum coatings in the aerospace field, and developed molybdenum wire doped with yttrium (Y), which improves the oxidation resistance by 40% at 1300°C. Toshiba’s molybdenum coating is used in the combustion chamber of gas turbines, extending component life by about 30%.

Massachusetts Institute of Technology (MIT): MIT’s Materials Science Laboratory has investigated the preparation of nanoscale molybdenum coatings to improve hardness (HV900) and wear resistance by controlling the grain size of the coating (5-20nm). Nano molybdenum coatings are widely used in semiconductor equipment.

1.4.2.2 Research focus

Composite coatings: Research on composite coatings of molybdenum with ceramics (e.g., ZrO₂, Al₂O₃) or metals (e.g., Ni, Cr) to improve the versatility of coatings. For example, molybdenum-Al₂O₃ composite coatings can achieve a hardness of HV1000 and a 50% increase in wear resistance.

Nano coating: Nano-scale molybdenum coating is prepared by cold spraying and laser-assisted spraying technology to reduce porosity and surface roughness (Ra≤0.1μm) and improve coating performance.

Intelligent spraying: Develop automated spraying equipment that combines artificial intelligence and sensor technology to monitor spraying parameters (e.g., temperature, airflow velocity) in real time to improve coating consistency and production efficiency.

1.4.2.3 Application Cases

Boeing: The turbofan engine of the Boeing 787 uses molybdenum-coated turbine blades, which improves high-temperature performance by 20% and extends maintenance intervals by 25%.

Mitsubishi Heavy Industries: Mitsubishi Heavy Industries applied a molybdenum coating in the combustion chamber of the gas turbine to resist high-temperature corrosion at 1400°C and extend the life of components by 40%.

1.4.3 Technical status and challenges

1.4.3.1 State of the art

At present, the technology of molybdenum spray wire has been relatively mature, and the main technical characteristics include:

High-purity molybdenum wire: The purity of the world’s mainstream molybdenum spray wire has reached more than 99.95%, and the oxidation resistance of some doped molybdenum wires has been significantly improved.

Advanced Spraying Processes: Plasma spraying and HVOF processes can form molybdenum coatings with a porosity of less than 1% and a binding strength of 80-100 MPa.

Automated production: The intelligent spraying equipment monitors the spraying parameters through the sensor, and the uniformity of the coating thickness is controlled within ±5μm.

1.4.3.2 Technical challenges

Insufficient oxidation resistance: Molybdenum is prone to form volatile oxides (MoO₃) in high-temperature oxidizing atmospheres, which limits its application in some high-temperature environments.

Coating porosity: Molybdenum coatings with traditional arc spraying have high porosity (3%-5%), which affects durability and corrosion resistance.

Cost control: The production cost of high-purity molybdenum wire is high (about 50-100 US dollars/kg), and the purification and drawing process need to be further optimized.

Adaptability of complex substrates: The uniformity of molybdenum coating is difficult to control on non-flat or complex-shaped substrates, and new spraying equipment needs to be developed.

1.4.4 Future research directions

1.4.4.1 New doping technologies

Develop more efficient doping elements (e.g., yttrium, cerium, zirconium) and doping processes to improve the oxidation resistance and ductility of molybdenum wires. For example, the oxidation rate of molybdenum wire doped with 0.5% zirconium can be reduced by 50% at 1400°C.

1.4.4.2 Advanced spraying technology

Promote cold spray and laser-assisted spraying technology to reduce thermal stress and oxide formation in coatings. Cold-sprayed molybdenum coatings can be used with a porosity as low as 0.2% and a binding strength of up to 120 MPa, making them suitable for high-precision applications.

1.4.4.3 Intelligent and green manufacturing

Develop an intelligent spraying system that uses machine learning to optimize spraying parameters and improve coating consistency. Research into environmentally friendly spraying processes to reduce energy consumption and exhaust emissions. For example, spraying equipment powered by renewable energy can reduce carbon emissions by 20%.

1.4.4.4 Composite and nano-coatings

Research molybdenum-based composite coatings and nanocoatings, combined with ceramics, metals, or other high-performance materials to form multifunctional coatings. For example, molybdenum-ZrO₂ composite coatings can increase wear resistance by up to 60 percent and are suitable for aerospace and energy applications.

1.4.4.5 Interdisciplinary applications

Explore the application of molybdenum coatings in biomedical, new energy and electronics. For example, in flexible electronic devices, molybdenum coatings can be used in the preparation of conductive films; In biological implants, molybdenum coatings improve corrosion resistance and biocompatibility.

READ MORE: Complete Guide to Molybdenum Spray Wire

===================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com|

Tel: +86 592 5129696 / 86 592 5129595