Directory

Chapter 1 Introduction

1.1 Definition and Overview of Molybdenum Rods

1.2 Historical Development of Molybdenum Rods

1.3 The Importance of Molybdenum Rods in Modern Industry

1.4 Global Market Status and Development Trends

Chapter 2 Material Properties of Molybdenum Rods

2.1 Chemical Composition and Atomic Structure of Molybdenum

2.2 Crystal Structure and Phase Changes of Molybdenum

2.3 Physical Properties of Molybdenum Rods

2.3.1 Density and Melting Point of Molybdenum Rods

2.3.2 Thermal Conductivity and Coefficient of Thermal Expansion of Molybdenum Rods

2.3.3 Conductivity and Resistivity of Molybdenum Rods

2.4 Mechanical Properties of Molybdenum Rods

2.4.1 Strength and Hardness of Molybdenum Rods

2.4.2 Ductility and Toughness of Molybdenum Rods

2.4.3 Creep Behavior of Molybdenum Rods at High Temperatures

2.5 Chemical Properties of Molybdenum Rods

2.5.1 Oxidation Resistance of Molybdenum Rods

2.5.2 Corrosion Resistance of Molybdenum Rods (Acids, Alkalis, Molten Salts, etc.)

2.6 Comparison of Molybdenum and Molybdenum-Based Alloys

2.7 Comparison of the Properties of Molybdenum Rods with Other High-Temperature Materials

2.8 Molybdenum Rod MSDS from CTIA GROUP LTD

Chapter 3 Preparation and Production Process of Molybdenum Rods

3.1 Acquisition of Molybdenum Raw Materials

3.1.1 Mining and Beneficiation of Molybdenum Ore

3.1.2 Purification of Molybdenum Concentrate

3.2 Powder Metallurgy Process of Molybdenum Rods

3.2.1 Preparation of Molybdenum Powder (Reduction Method, Atomization Method)

3.2.2 Powder Particle Size and Purity Control

3.2.3 Compression Molding (Cold Isostatic Pressing, Molding)

3.3 Sintering Process of Molybdenum Rods

3.3.1 Vacuum Sintering

3.3.2 Hydrogen Protection Sintering

3.3.3 High-Temperature Sintering Equipment and Parameter Optimization

3.4 Thermal Processing Technology of Molybdenum Rods

3.4.1 Forging Process

3.4.2 Rolling Process

3.4.3 Drawing Process

3.5 Surface Treatment Technology of Molybdenum Rods

3.5.1 Mechanical Polishing

3.5.2 Chemical Cleaning

3.5.3 Surface Coatings (Anti-Oxidation Coatings, etc.)

3.6 Quality Control and Process Optimization of Molybdenum Rods

3.6.1 Defect Control in the Production Process

3.6.2 Monitoring and Optimization of Process Parameters

Chapter 4 Types and Specifications of Molybdenum Rods

4.1 Classification by Composition

4.1.1 High Purity Molybdenum Rods (Purity ≥99.95%)

4.1.2 Doped Molybdenum Rods (TZM, Mo-La, Mo-W, etc.)

4.2 Classification by Surface State

4.2.1 Black Molybdenum Rods

4.2.2 Polishing Molybdenum Rods

4.2.3 Cleaning Molybdenum Rods

4.3 Classification by Size and Shape

4.3.1 Round Molybdenum Rods

4.3.2 Square and Other Special-Shaped Molybdenum Rods

4.3.3 Micro Molybdenum Rods and Large Molybdenum Rods

4.4 Customized Molybdenum Rod Design

4.4.1 Customer Demand Analysis

4.4.2 Special Specifications and Performance Customization

Chapter 5 Performance Testing and Evaluation of Molybdenum Rods

5.1 Test of Mechanical Properties of Molybdenum Rods

5.1.1 Tensile Test of Molybdenum Rods

5.1.2 Compression Test of Molybdenum Rods

5.1.3 Bending and Shear Testing

5.2 High Temperature Performance Test of Molybdenum Rods

5.2.1 Creep Test of Molybdenum Rods

5.2.2 Thermal Fatigue Test of Molybdenum Rods

5.2.3 Test of Oxidation Resistance of Molybdenum Rods

5.3 Microstructure Analysis of Molybdenum Rods

5.3.1 Scanning Electron Microscopy (SEM) Analysis

5.3.2 X-ray Diffraction (XRD) Analysis

5.3.3 Energy Spectroscopy (EDS)

5.4 Chemical Properties Test of Molybdenum Rods

5.4.1 Corrosion Resistance Test of Molybdenum Rods

5.4.2 Chemical Stability Assessment of Molybdenum Rods

5.5 Failure Analysis of Molybdenum Rods

5.5.1 Analysis of Fracture Mechanism of Molybdenum Rods

5.5.2 Fatigue and Wear Analysis of Molybdenum Rods

5.5.3 Life Prediction Model for Molybdenum Rods

Chapter 6 Production Equipment for Molybdenum Rods

6.1 Raw Material Handling Equipment for Molybdenum Rods

6.1.1 Crushing and Grinding Equipment

6.1.2 Purification Equipment (Roasting Furnaces, Reduction Furnaces)

6.2 Powder Metallurgy Equipment for Molybdenum Rods

6.2.1 Mixing and Pressing Equipment

6.2.2 Sintering Furnaces (Vacuum Furnaces, Atmosphere Furnaces)

6.3 Thermal Processing Equipment for Molybdenum Rods

6.3.1 Forging Equipment

6.3.2 Rolling Mills and Drawing Machines

6.4 Surface Treatment Equipment for Molybdenum Rods

6.4.1 Polishing Machines

6.4.2 Cleaning Equipment

6.5 Testing Equipment for Molybdenum Rods

6.5.1 Non-Destructive Testing Equipment (Ultrasonic, X-ray)

6.5.2 Dimensional and Surface Quality Testing Equipment

6.6 Automatic and Intelligent Production Equipment for Molybdenum Rods

6.6.1 Automatic Control of Production Lines

6.6.2 Intelligent Monitoring and Data Analysis

Chapter 7 Application Fields of Molybdenum Rods

7.1 High-Temperature Furnaces and Thermal Equipment

7.1.1 Molybdenum Rods as Heating Elements

7.1.2 Support and Fixing Parts

7.2 Electronics and Semiconductor Industry

7.2.1 Electrode Materials

7.2.2 Sputtering Targets

7.2.3 Vacuum Tubes and Ion Source Components

7.3 Aerospace

7.3.1 High-Temperature Structural Parts

7.3.2 Propulsion System Components

7.4 Glass and Ceramic Industry

7.4.1 Glass Melting Electrodes

7.4.2 Ceramic Sintering Supports

7.5 Medical and Scientific Research

7.5.1 X-ray Tube Targets

7.5.2 Laboratory High-Temperature Experimental Equipment

7.6 Emerging Applications

7.6.1 3D Printing and Additive Manufacturing

7.6.2 Nuclear Industry Applications

Chapter 8 Domestic and Foreign Standards and Specifications for Molybdenum Rods

8.1 International Standards for Molybdenum Rods

8.1.1 ASTM Standards (ASTM B387, etc.)

8.1.2 ISO Standards

8.2 Domestic Standards for Molybdenum Rods

8.2.1 GB/T Standard (GB/T 3462, etc.)

8.2.2 Industry Standards and Enterprise Standards

8.3 Certification and Compliance of Molybdenum Rods

8.3.1 Material Certification Process

8.3.2 Environmental and Safety Compliance

8.4 Standard Comparison and Application Scenario Analysis of Molybdenum Rods

Chapter 9 Processing, Use and Maintenance of Molybdenum Rods

9.1 Processing Technology of Molybdenum Rods

9.1.1 Cutting (Wire Cutting, Laser Cutting)

9.1.2 Machining (Turning, Milling, Drilling)

9.1.3 Welding and Joining Technology

9.2 Environmental Requirements for the Use of Molybdenum Rods

9.2.1 Vacuum and Inert Atmospheres

9.2.2 High Temperature Oxidation Environmental Protection

9.3 Installation and Fixing of Molybdenum Rods

9.3.1 Installation Process and Fixture Design

9.3.2 Thermal Expansion Matching Design

9.4 Maintenance and Cleaning of Molybdenum Rods

9.4.1 Surface Cleaning Methods

9.4.2 Periodic Inspection and Maintenance

9.5 Safety Operation Specifications for Molybdenum Rods

9.5.1 Precautions for High-Temperature Operation

9.5.2 Chemical Handling Safety Specifications

Chapter 10 Recycling and Sustainable Development of Molybdenum Rods

10.1 Molybdenum Rods Recycling Process

10.1.1 Waste Collection and Sorting

10.1.2 Recycling and Purification Technology

10.2 Environmental Impact of Molybdenum Rods and Green Production

10.2.1 Energy Consumption and Emissions in the Production Process

10.2.2 Environmental Protection Process Improvement

10.3 Circular Economy and Sustainable Development Strategy of Molybdenum Rods

Chapter 11 The Latest Technology and Future Trend of Molybdenum Rods

11.1 Research and Development Progress of Molybdenum-Based Alloys

11.1.1 Optimization of TZM and Mo-La Alloys

11.1.2 New Doping Technologies

11.2 Development of Nanostructured Molybdenum Rods

11.3 Intelligent Production and Testing Technology

11.3.1 Online Monitoring and Big Data Analysis

11.3.2 Application of Artificial Intelligence in the Production of Molybdenum Rods

11.4 The Potential of Molybdenum Rods in the Field of New Energy

11.4.1 Hydrogen Energy and Energy Storage Applications

11.4.2 High-Temperature Superconducting Material Support

11.5 Future Research Directions and Challenges of Molybdenum Rods

Appendix

- Glossary of Terms

- References

Chapter 1 Introduction

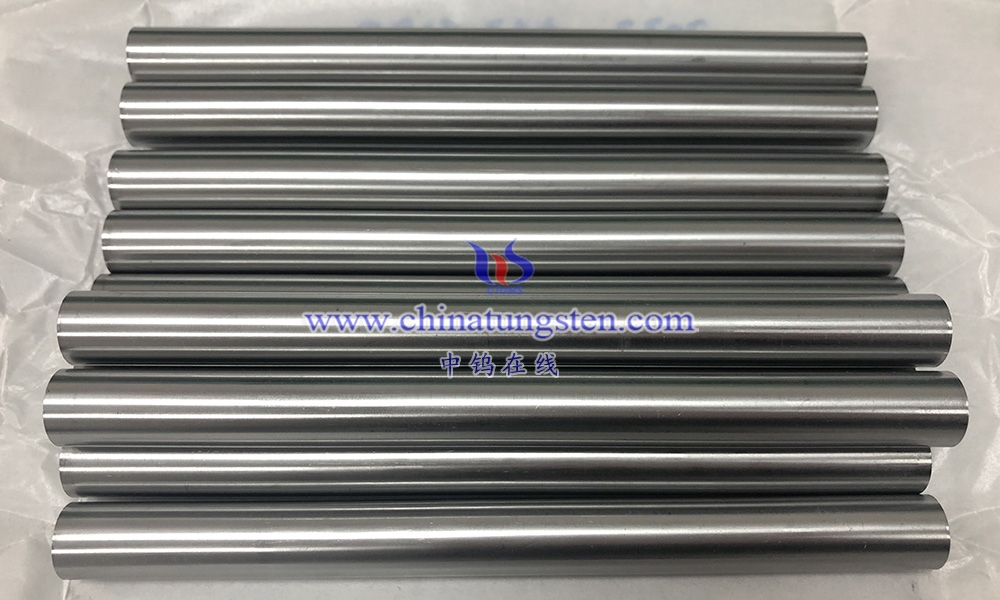

1.1 Definition and overview of molybdenum rods

Molybdenum rod is a rod-like material made of high-purity molybdenum or molybdenum-based alloys (such as TZM, Mo-La), usually produced by powder metallurgy process or thermal processing process, with excellent high-temperature properties, mechanical strength and chemical stability. The purity of molybdenum rods usually reaches more than 99.95%, the diameter ranges from a few millimeters to tens of millimeters, and the length can be customized according to the application needs. The surface state of molybdenum rod includes black (unpolished, surface oxide layer retained), polished (mechanical or chemical polishing) and washed (removal of surface impurities) to meet the needs of different application scenarios.

As a refractory metal, molybdenum has a high melting point (2623 °C), a low coefficient of thermal expansion (about 4.8×10⁻⁶/°C), and a good thermal conductivity (about 138 W/m·K) and conductivity, making it excellent in high temperatures and extreme environments. The main characteristics of molybdenum rod include high temperature resistance, corrosion resistance, creep resistance and good processing properties, which make it widely used in high-temperature furnaces, electronic semiconductors, aerospace, glass manufacturing and other industries. In addition, molybdenum rods can be doped with elements such as titanium, zirconium, lanthanum, etc., to further optimize their high-temperature strength and oxidation resistance.

Molybdenum rods come in a variety of forms, including round rods, square rods and other special-shaped rods, and their production process involves a complete process from molybdenum ore purification to powder metallurgy, thermal processing and surface treatment. The performance and quality of molybdenum rods are affected by factors such as raw material purity, sintering process and processing accuracy, so the process parameters need to be strictly controlled during the production process to ensure product consistency. Molybdenum rods are used in applications with different requirements for size, surface condition and performance, such as high purity and surface finish in the semiconductor industry, and oxidation resistance and mechanical strength in high-temperature furnaces.

1.2 Historical development of molybdenum rods

The history of molybdenum can be traced back to the end of the 18th century, when the Swedish chemist Carl Wilhelm Scheele first isolated molybdenum acid from molybdenum ore in 1778, laying the foundation for the study of molybdenum chemistry. In 1781, Peter Jacob Hjelm succeeded in preparing metal molybdenum by reducing molybdenum acid, marking the official discovery of molybdenum as a metallic element. At the beginning of the 19th century, molybdenum was mainly used for laboratory research due to its rarity and difficulty of extraction, and it was not until the beginning of the 20th century, with the advancement of metallurgical technology, that the industrial production of molybdenum gradually became possible.

As a kind of molybdenum products, the development of molybdenum rod is closely related to the maturity of powder metallurgy technology. At the beginning of the 20th century, molybdenum rods began to be used in the manufacture of light bulbs and vacuum tubes, and became an alternative material to tungsten wire due to its high melting point and good electrical conductivity. In the 1920s, industrial production in the United States and Germany promoted the use of molybdenum rods in high-temperature furnaces and in the glass industry. During World War II, molybdenum rods were valued for their potential in the field of superalloys and aerospace, especially in jet engines and rocket propulsion systems.

In the mid-to-late 20th century, with the rise of the semiconductor industry, the use of molybdenum rods as sputtering targets and electrode materials increased significantly. The development of TZM (titanium-zirconium-molybdenum) alloys and Mo-La (molybdenum-lanthanum) alloys further improved the high temperature performance and creep resistance of molybdenum rods, enabling their use in more demanding environments. Since the 21st century, the production process of molybdenum rods has been continuously optimized, and the introduction of automation and intelligent technologies has improved production efficiency and product quality. For example, modern molybdenum rod production uses vacuum sintering and precision rolling technology to produce high-purity, dimensional-precision rods.

China’s molybdenum industry has grown rapidly over the past few decades, becoming the world’s largest producer and consumer of molybdenum. Thanks to the abundant molybdenum ore resources and advanced production technology, Chinese enterprises occupy an important position in the R&D and production of molybdenum rods, which promotes the popularity of molybdenum rods in the global market.

1.3 The importance of molybdenum rods in modern industry

Molybdenum rod has an irreplaceable position in modern industry, and its importance stems from its unique material properties and wide range of applications. The following describes the role of molybdenum rod in modern industry from several key aspects:

High-temperature applications: The high melting point and creep resistance of molybdenum rods make them ideal materials for high-temperature furnaces (e.g., vacuum furnaces, hydrogen furnaces) and are commonly used in heating elements, support rods, and heat screens. Molybdenum rods can work stably in environments up to 1800°C, which is significantly better than traditional metal materials.

Electronics & Semiconductor Industry: Molybdenum rods are widely used as sputtering targets in thin film deposition processes for the production of integrated circuits, solar cells and flat panel displays. Its high purity and homogeneous microstructure ensure film quality. In addition, molybdenum rods are also used as electrode materials for vacuum tubes and ion sources.

Aerospace: Molybdenum rods are used in the aerospace industry to manufacture high-temperature structural parts such as jet engine nozzles and rocket propulsion system components. Its low coefficient of thermal expansion and high strength ensure reliability under extreme temperature and stress conditions.

Glass & Ceramics Industry: Molybdenum rods are used as electrodes in glass melting furnaces because they are resistant to high-temperature corrosion and chemically stable, and can withstand the erosion of molten glass. In addition, molybdenum rods are also used as support components in the ceramic sintering process.

Medical & Research: Molybdenum rods are used as targets in X-ray tubes to generate high-energy X-rays for medical diagnostics and materials analysis. In the field of scientific research, molybdenum rods are a key component of high-temperature experimental equipment, supporting materials science and physics research.

The importance of molybdenum rods is also reflected in their sustainability. Molybdenum is a recyclable metal, and waste molybdenum rods can be reused through the purification process, which meets the needs of modern industry for green manufacturing. The diverse applications of molybdenum rods have driven technological progress in several industries, such as new energy (photovoltaics, hydrogen energy) and high-end manufacturing.

1.4 Global market status and development trends

The global molybdenum rod market has shown steady growth in recent years, mainly due to increased demand from the electronics, aerospace and energy industries. According to industry reports, the global molybdenum market size will be about $200 million in 2024, of which molybdenum rod accounts for a considerable proportion as an important product form. China is the world’s largest producer of molybdenum, accounting for more than 40% of global production, followed by countries such as the United States, Chile and Peru.

The current state of the market

Production and supply: Chinese enterprises occupy a dominant position in the production of molybdenum rods, relying on rich molybdenum ore resources and mature powder metallurgy technology.

Demand-driven: The rapid development of the electronics and semiconductor industries is driving the demand for high-purity molybdenum rods, especially in 5G technology, AI chips, and photovoltaics. The demand for TZM and Mo-La alloy bars in the aerospace sector is also increasing.

Price fluctuations: Molybdenum rod prices are greatly affected by raw material supply, geopolitics and market demand. In recent years, molybdenum prices have generally stabilized, but production costs have increased due to rising energy costs and stricter environmental regulations.

Trends

High-performance alloy rods: The research and development of doped molybdenum rods such as TZM and Mo-La is the focus of the future, aiming to improve high-temperature strength and oxidation resistance to meet the needs of the aerospace and nuclear industries.

Green production: With the improvement of environmental protection requirements, molybdenum rod manufacturers are adopting low-energy, low-emission processes, such as green purification technology and waste recycling systems.

Smart manufacturing: Automated production lines and smart inspection technologies, such as in-line X-ray inspection, are changing the way molybdenum rods are produced, improving efficiency and consistency.

Emerging Applications: The emerging potential of molybdenum rods in new energy fields such as hydrogen electrolyzers and high-temperature superconducting materials, as well as additive manufacturing (3D printing), is expected to drive further growth of the market.

Regional Market Dynamics: China continues to lead the global molybdenum rod market, while demand in India and Southeast Asia is growing rapidly, making it a new market hotspot.

Challenge

Raw material supply risk: The regional concentration of molybdenum ore resources may lead to supply fluctuations.

Technical barriers: The production of high-purity molybdenum rods and special alloy bars has extremely high technical requirements, and it is difficult for small and medium-sized enterprises to enter the market.

Environmental pressure: The energy consumption and emission problems in the process of molybdenum purification and processing need to be further solved.

READ MORE: Encyclopedia of Molybdenum Rod

===================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

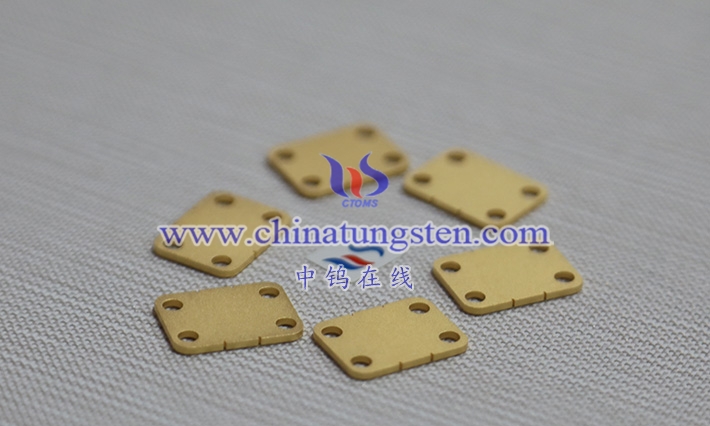

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com|

Tel: +86 592 5129696 / 86 592 5129595