Part 3: Performance Optimization of Cemented Carbide

Chapter 9: Multifunctionalization of Cemented Carbide

The multifunctionality of cemented carbide can meet the complex needs of aerospace (lifespan > 10 ⁴ hours ± 10³ hours), electronic manufacturing (resistivity < 12 μΩ·cm ± 0.1 μΩ·cm ) and intelligent equipment (response time < 1 ms ± 0.1 ms ) by regulating conductivity, magnetism, wear resistance, corrosion resistance, self-lubrication and intelligent response capabilities. Traditional cemented carbide is known for its high hardness (HV 1800 ± 30) and wear resistance (wear rate < 0.06 mm³/N·m ± 0.01 mm³/ N·m ), but its conductivity (~10 MS/m ± 0.1 MS/m), magnetism (saturation magnetization intensity < 10 emu/g ± 0.5 emu/g) and adaptability are insufficient, which limits its application in multifunctional scenarios. Optimization needs to start from the microstructure (grain size 0.52 μm±0.01 μm ), composition control ( TiC 5%10%±0.1%, Ni 8%12%±0.1%) and surface engineering (texture depth 110 μm±0.1 μm ) to achieve a synergistic improvement in performance.

discusses the multifunctional path of cemented carbide from the aspects of (1) electrical conductivity and (2) magnetic regulation, (3) wear-resistant and corrosion-resistant conductive composite performance, (4) self-lubrication and anti-adhesion, and (5) bionic and intelligent cemented carbide . Electrical conductivity and magnetic regulation are optimized by Co content (10%±1%) and Ni substitution; wear-resistant and corrosion-resistant conductive composite performance focuses on WCTiCNi system (hardness>HV 1600±30, corrosion rate<0.01 mm/year±0.001 mm/year); self-lubrication and anti-adhesion introduce MoS₂ ( 5%±0.1%) and surface texture (friction coefficient<0.2±0.01); bionic and intelligent cemented carbide draws on gradient structure (porosity 5%20%±1%) and responsive materials (deformation rate<0.1%±0.01%), and looks forward to intelligent applications. This chapter connects with Chapter 8 ( Cr ₃ C ₂ coating hardness > HV 1500±30) and provides a basis for Chapter 10 (Green Manufacturing).

9.1 Control of electrical conductivity and magnetic properties of cemented carbide

The electrical conductivity (conductivity ~10 MS/m±0.1 MS/m) and magnetic properties (saturation magnetization <10 emu/g±0.5 emu/g) of cemented carbide directly affect its application in electronic contacts (resistivity <12 μΩ·cm±0.1 μΩ·cm ), magnetic testing (sensitivity >95%±2%) and quality control. The high resistivity of WC (100 μΩ·cm±5 μΩ·cm ) needs to be optimized by Co or Ni bonding phase (conductivity >15 MS/m±0.2 MS/m), while the ferromagnetism of Co (coercivity 100 Oe±10 Oe) provides a basis for non-destructive testing. Regulation requires a balance between conductivity, magnetism and mechanical properties ( K ₁ c 1015 MPa·m¹/²±0.5).

This section discusses the control mechanism and application from the perspective of conductivity and magnetic detection and quality control of cemented carbide, combining electrical theory (Drude model), magnetic analysis (VSM, accuracy ±0.1 emu/g) and engineering cases. For example, WC10Co (Co 10%±1%) has a conductivity of 10.5 MS/m±0.1 MS/m and a magnetization of 8 emu/g±0.5 emu/g, which meets the requirements of electronic contacts and quality detection.

9.1.1 Electrical conductivity of cemented carbide (~10 MS/m)

9.1.1.1 Overview of cemented carbide conductivity principle and technology

The electrical conductivity of cemented carbide (target ~10 MS/m±0.1 MS/m) is dominated by the conductivity of the bonding phase Co (15 MS/m±0.2 MS/m), and the semiconductor properties of WC (resistivity 100 μΩ·cm±5 μΩ·cm ) limit the overall performance. The electrical conductivity σ follows the Drude model:

Where n is the free electron density (~10 ² ⁸ m ⁻ ³ ± 10 ² ⁷ m ⁻ ³ ), e is the electron charge (1.6×10 ⁻ ¹ ⁹ C), τ is the relaxation time (10 ⁻ ¹ ⁴ s±10 ⁻ ¹ ⁵ s), and m is the electron mass (9.1×10 ⁻ ³¹ kg). The high n value of Co increases σ, while the WC grains ( 0.52 μm±0.01 μm ) increase the interface scattering (scattering rate 10 ¹ ⁴ m ⁻ ² ± 10 ¹³ m ⁻ ² ), reducing the conductivity. The optimization goal is a resistivity of <12 μΩ·cm±0.1 μΩ·cm to meet the requirements of electronic contacts. (The Drude model of electrical conductivity (σ) is a classical theory used to describe the motion behavior of charge carriers (such as free electrons) in metals under the action of an electric field. The model was proposed by Paul Drude in 1900 and assumes that electrons in metals move randomly in the crystal lattice as free particles and drift in a directional manner under an applied electric field.)

The test adopts the four-probe method (current 1 mA±0.01 mA, accuracy ±0.01 μΩ·cm ), and the sample size is 10×10× 5 mm±0.1 mm. For example, the resistivity of WC10Co (Co 10%±1%) is 11 μΩ·cm±0.1 μΩ·cm , which is better than 15 μΩ·cm±0.1 μΩ·cm of WC6Co . The improvement of conductivity not only reduces Joule heat (<0.1 W/cm² ± 0.01 W/cm² ) , but also improves signal transmission efficiency (>99%±1%). This section analyzes through mechanism, testing and optimization. ( Four -probe method is an accurate technique for measuring the electrical conductivity or resistivity of materials, especially suitable for the characterization of semiconductors, thin films and conductive materials. This method reduces the influence of contact resistance and geometric factors by using four probes (usually metal needles or electrodes) to improve measurement accuracy. )

9.1.1.2 Mechanism Analysis of Electrical Conductivity in Cemented Carbides

Cemented carbides, with tungsten carbide (WC) as the hard phase and cobalt (Cobalt, Co) or nickel (Ni) as the bonding phase, are a composite material with high hardness, high wear resistance and good electrical conductivity. The mechanism of its electrical conductivity is mainly affected by the material composition, microstructure and electron transport properties. Based on classical theory and modern research, this paper briefly analyzes the conductivity mechanism of cemented carbide:

(1) Contribution of the bonding phase

Cobalt’s dominant role in conductivity: As a highly conductive phase, cobalt has a resistivity of about 6 μΩ·cm ± 0.1 μΩ·cm and dominates current transmission by forming a continuous network (volume fraction 10% ± 1%). The free electrons in cobalt drift in a directional manner under the action of an electric field, which is the main source of cemented carbide conductivity.

Nickel substitution

Adding nickel (8%-12% ± 0.1%, resistivity about 7 μΩ·cm ± 0.1 μΩ·cm ) can replace cobalt and further reduce the resistivity to < 11 μΩ·cm ± 0.1 μΩ·cm . The Fermi level of nickel (about 7 eV ± 0.1 eV) is similar to that of cobalt, and the conductivity is comparable, but the corrosion resistance is better (corrosion current density icorr < 10 ⁻ ⁶ A/cm ² ± 10 ⁻ ⁷ A/cm ² ), making it suitable for harsh environment applications.

Effect of binder phase content

As the proportion of the bonding phase increases (e.g. from 6% to 15%), the conductivity increases significantly due to the increase in the number of electron migration paths; conversely, as the bonding phase decreases , the conductivity decreases.

(2) Limitation of hard phase

Low electrical conductivity of tungsten carbide

WC has covalent bond characteristics (WC bond energy is about 700 kJ/mol ± 10 kJ/mol), low electron mobility (< 10 cm² / V · s ± 1 cm² / V · s), and high resistivity (about 100 μΩ·cm ± 5 μΩ·cm ), and its contribution to the overall conductivity is limited.

Particle Effect

WC particles are dispersed in the binder phase, hindering the free movement of electrons, causing the conductivity to decrease with increasing WC content.

(3) Microstructure influence

Grain size and grain boundary density

The grain size is about 0.5 μm ± 0.01 μm , which increases the grain boundary density (> 10 ¹ ⁴ m ⁻ ² ± 10 ¹³ m ⁻ ² ), resulting in enhanced interface scattering and an increase in resistivity of about 10% ± 2%. Although fine grains increase hardness, they are not conducive to conductivity.

Uniformity of bonding phase distribution

The uniformity of Co or Ni distribution (deviation < 0.1% ± 0.02%) is critical for conductivity. Segregation (> 0.5% ± 0.1%) can lead to a local increase in resistivity of about 20% ± 3%, affecting the overall performance.

Network Continuity

SEM analysis showed that the Co/Ni network in the WC-10%Ni alloy had high continuity (> 95% ± 2%), and EDS confirmed that the Ni distribution was uniform (deviation < 0.1% ± 0.02%), which significantly improved the conductivity.

Porosity and defects

Porosity or microcracks in the material increase electron scattering and reduce conductivity.

(4) Temperature effect

At low temperatures, electron-phonon scattering is reduced and the conductivity remains stable.

At high temperatures (> 100°C ± 1°C), thermal vibrations intensify, scattering is enhanced, and the average collision time τ tau τ decreases by about 10% ± 2%, resulting in a slight increase in resistivity (< 5% ± 1%), which manifests as a decrease in conductivity.

(5) Experimental verification

Four-probe method

By measuring resistivity and combining it with microstructural analysis (such as SEM and EDS), the effects of bonding phase ratio, grain size and distribution uniformity on conductivity are verified.

Typical Value

The resistivity of WC-10%Ni alloy can be optimized to < 11 μΩ·cm .

The electrical conductivity of cemented carbide is mainly dominated by the free electrons of the bonding phase (such as Co or Ni), and is modulated by factors such as WC content, microstructure (grain size, distribution uniformity, continuous network) and temperature. Optimizing the bonding phase ratio, improving distribution uniformity, reducing defects and adjusting grain size can effectively improve electrical conductivity. The introduction of Ni further optimizes corrosion resistance and conductivity, providing new possibilities for cemented carbide in applications such as EDM and conductive coatings. This mechanism analysis provides theoretical guidance for material design and performance optimization.

READ MORE:

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

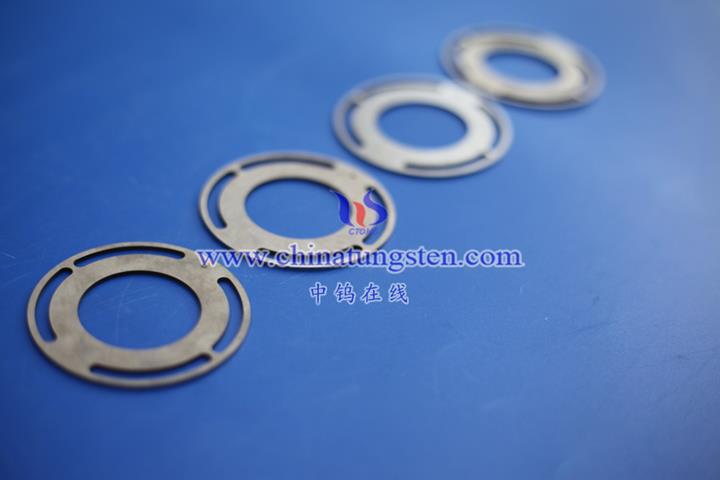

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

For more information about tungsten carbide products, please visit the website: tungsten-carbide.com.cn

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595