Table of contents

Chapter 1 Introduction

1.1 Overview of Molybdenum Copper Sheet

1.2 Composition and structure of molybdenum -copper composite materials

1.3 Importance of Molybdenum Copper Sheet in Materials Science

Chapter 2 Material properties of molybdenum copper sheet

2.1 Basic properties of molybdenum and copper

2.2 Density of molybdenum copper sheet

2.3 Mechanical properties of molybdenum copper sheet

2.3.1 Hardness of molybdenum copper sheet

2.3.2 Toughness of molybdenum copper sheet

2.3.3 Ductility of Mo-Cu Sheet

2.3.4 Mechanical strength of molybdenum copper sheet

2.3.5 Fatigue resistance of molybdenum copper sheet

2.4 Chemical properties of molybdenum copper sheets

2.4.1 Corrosion resistance of molybdenum copper sheet

2.4.2 Antioxidation properties of molybdenum copper sheets

2.4.3 Acid and alkali resistance of molybdenum copper sheet

2.5 Thermal properties of molybdenum copper sheet

2.5.1 Thermal conductivity and thermal diffusivity

2.5.2 Thermal expansion behavior and stability

2.5.3 High temperature resistance

2.6 Electrical properties of molybdenum copper sheets

2.6.1 Conductivity and resistance characteristics

2.6.2 Electrical contact performance

2.6.3 Electrochemical stability

2.7 Comparison between molybdenum copper sheet and other materials

2.8 CTIA GROUP LTD Molybdenum Copper Sheet MSDS

Chapter 3 Classification of Molybdenum Copper Sheets

3.1 Classification by brand (typical) Molybdenum copper sheet

3.1.1 Mo85Cu15

3.1.2 Mo80Cu20

3.1.3 Mo70Cu30

3.1.4 Mo60Cu40

3.1.5 Mo50Cu50

3.2 Classification of Molybdenum Copper Sheets by Manufacturing Process

3.2.1 Molybdenum copper sheet manufactured by powder metallurgy

3.2.2 Molybdenum-copper sheet manufactured by melt infiltration

3.3 Classification of Molybdenum Copper Sheets by Application

3.3.1 General Molybdenum Copper Sheet

3.3.2 High frequency molybdenum copper sheet

3.3.3 Aerospace Molybdenum Copper Sheet

3.3.4 Photoelectric device type molybdenum copper sheet

Chapter 4 Preparation Technology of Molybdenum Copper Sheet

4.1 Preparation of molybdenum copper sheet by powder metallurgy technology

4.1.1 Process flow of powder metallurgy technology

4.1.2 Advantages and limitations of powder metallurgy technology

4.2 Preparation of Molybdenum-Copper Sheet by Infiltration Method

4.2.1 Process flow of melt infiltration

4.2.2 Advantages and limitations of the infiltration method

4.3 Application of 3D printing technology in the preparation of molybdenum copper sheets

Chapter 5 Main production equipment of molybdenum copper sheet

5.1 Molybdenum copper sheet powder metallurgy technology production equipment

5.1.1 Powder preparation equipment

5.1.1.1 Ball mill

5.1.1.2 Atomization equipment

5.1.2 Powder molding equipment

5.1.2.1 Hydraulic press (for cold forming of molybdenum-copper billets )

5.1.2.2 Isostatic Press

5.1.3 Sintering equipment

5.1.3.1 Vacuum sintering furnace

5.1.3.2 Hot Press Sintering Furnace

5.1.4 Post-processing equipment

5.1.4.1 Heat treatment furnace

5.1.4.2 Precision grinding machine

5.2 Molybdenum-copper sheet infiltration production equipment

5.2.1 Hydraulic press (for pressing molybdenum powder into shape )

5.2.2 Vacuum sintering furnace (for sintering of molybdenum skeleton and infiltration of copper )

Chapter 6 Molybdenum Copper Sheet Performance Test Methods and Equipment

6.1 Density test of molybdenum copper sheet

6.1.1 Principle and operation of Archimedes drainage method

6.2 Porosity test of molybdenum copper sheet

6.2.1 Metallographic microscope observation and calculation

6.3 Tensile test of molybdenum copper sheet

6.3.1 Use of universal material testing machine

6.4 Bending test of molybdenum copper sheet

6.4.1 Three-point bending method

6.4.2 Four-point bending method

6.5 Impact toughness test of molybdenum copper sheet

6.5.1 Key points for pendulum impact test operation

6.6 Thermal conductivity test of molybdenum copper sheet

6.6.1 Principle and application of laser flash method

6.7 Thermal Expansion Coefficient Test of Molybdenum Copper Sheet

6.7.1 Use of Thermomechanical Analyzer (TMA)

6.8 Resistivity test of molybdenum copper sheet

6.8.1 Four-probe measurement process

6.9 Contact resistance test of molybdenum copper sheet

6.9.1 DC voltage drop method operating specifications

Chapter 7 Application Fields of Molybdenum Copper Sheets

7.1 Application of Molybdenum Copper Sheet in Electronic Industry

7.1.1 Packaging materials

7.1.2 Integrated Circuit Substrates

7.1.3 Heat Dissipation Components in Microwave Devices

7.1.4 Structural Support Components in Microwave Devices

7.1.5 Heat sink materials

7.1.6 RF Module

7.1.7 LED heat dissipation substrate

7.2 Application of Molybdenum Copper Sheet in Aerospace Field

7.2.1 Aircraft Metal Components

7.2.2 Thermal protection materials for spacecraft

7.2.3 Missile and spacecraft components

7.2.4 Radar system radiator

7.2.5 Military Electronic Packaging

7.3 Application of Molybdenum Copper Sheets in Energy and Thermal Management

7.3.1 Power Electronic Devices

7.3.2 Nuclear power equipment

7.3.3 Renewable energy systems

7.3.4 Electric Vehicle Battery Thermal Management

7.4 Molybdenum copper sheet in other emerging application areas

7.4.1 Medical equipment

7.4.2 7G Communication Base Station

7.4.3 Laser and optical system

7.4.4 Additive Manufacturing and Customized Components

Chapter 8 Market and Industry Status of Molybdenum Copper Sheet

8.1 Global Molybdenum Copper Sheet Market Overview

8.2 Major Manufacturers of Molybdenum Copper Sheets – CTIA GROUP LTD

8.3 Market Demand and Development Trend of Molybdenum Copper Sheet

8.4 Challenges and Opportunities Facing the Molybdenum Copper Sheet Market

Chapter 9 Future Development of Molybdenum Copper Sheet

9.1 Potential of new preparation technology for molybdenum copper sheet

9.2 Research directions for optimizing the performance of molybdenum copper sheets

9.3 Expansion of cross-industry applications of molybdenum copper sheets

Chapter 10 Domestic and International Standards for Molybdenum Copper Sheets

10.1 Chinese National Standard for Molybdenum Copper Sheet

10.2 International Standards for Molybdenum Copper Sheets

Molybdenum copper sheet standards in Europe, America, Japan, South Korea and other countries around the world

appendix:

Molybdenum Copper Sheet Glossary

References

Chapter 1 Introduction

1.1 Overview of Molybdenum Copper Sheet

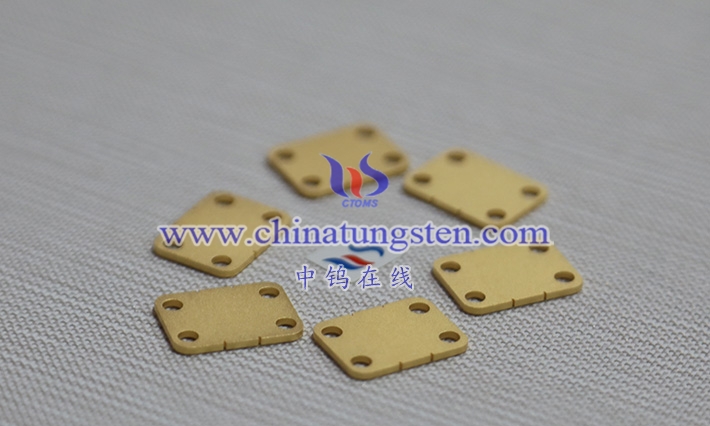

Molybdenum copper sheet is a composite material composed of molybdenum and copper , usually used in the form of thin sheets or plates in the fields of electronics, aerospace, energy and high-temperature industries. It combines the high melting point, corrosion resistance and excellent thermal stability of molybdenum with the high electrical conductivity and thermal conductivity of copper to form an advanced material with excellent mechanical properties and thermoelectric properties. Molybdenum copper sheet is mainly prepared by powder metallurgy technology, mixing molybdenum powder and copper powder in a specific proportion, pressing and sintering, or using melt infiltration to infiltrate liquid copper into the molybdenum matrix to form a composite structure.

Molybdenum copper sheet has the following remarkable characteristics: high thermal conductivity makes it excellent in thermal management and suitable for heat sinks and heat sinks; low thermal expansion coefficient ensures its dimensional stability in high temperature environment; by adjusting the molybdenum -copper ratio, thermal conductivity, electrical conductivity and mechanical strength can be customized to meet diverse application requirements; molybdenum ‘s high melting point (about 2623°C) and corrosion resistance enable it to serve for a long time in extreme environments. Typical applications include heat dissipation substrates in electronic packaging, power semiconductor devices, microwave devices, and aerospace thermal management components. Since the mid-to-late 20th century, with the growth of demand for high-performance electronic devices and high-temperature applications, the research and development and production technology of molybdenum copper sheets have been significantly improved.

READ MORE: What Is Molybdenum Copper Sheet

===================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com|

Tel: +86 592 5129696 / 86 592 5129595