Molybdenum crucible has no special international certification standards, but it usually follows some international certifications and specifications, especially those related to its manufacturing materials and use environment. The following are some international certification and standard systems that may be applicable to molybdenum crucibles:

1. ISO (International Organization for Standardization) certification

ISO 9001:2015 – Quality Management Systems: This is a general quality management standard that is not specific to molybdenum crucibles, but many companies that produce molybdenum crucibles follow this standard to ensure quality control, product consistency and customer satisfaction in their production processes.

ISO 13743 — Technical requirements for molybdenum and molybdenum alloys: This is a standard for molybdenum and molybdenum alloys, applicable to the production raw materials of molybdenum crucibles, and specifies the chemical composition, physical properties and other technical requirements of molybdenum and its alloys.

ISO 9000 series – quality management basics and terminology: If molybdenum crucible manufacturers obtain ISO 9000 series certification, it means that their products meet internationally recognized quality management requirements.

ISO 6892-1:2019 — Tensile test methods for metallic materials: Molybdenum crucibles need to have a certain strength when used under high temperature conditions. The ISO 6892-1 standard can be used for tensile tests on molybdenum crucible materials to evaluate their mechanical properties in extreme environments.

2. ASTM (American Society for Testing and Materials) Standards

ASTM B386 —Technical requirements for molybdenum and molybdenum alloys: This standard applies to molybdenum and its alloy materials, specifies the chemical composition, mechanical properties, etc. of the materials, and directly affects the manufacture and use of molybdenum crucibles.

ASTM B387 —Test methods for molybdenum crucibles and molybdenum alloy materials: Performance tests of molybdenum crucibles, including strength, heat resistance and corrosion resistance, usually need to be conducted according to this standard.

ASTM B537 — Standard Specification for Molybdenum Alloy Materials and Products: Product specifications for molybdenum crucibles may be based on this standard to ensure their stability and corrosion resistance in high temperature environments.

ASTM F15 — Testing of molybdenum alloy materials in special high-temperature applications: Applicable to molybdenum alloy materials in high-temperature environments. Molybdenum crucibles are often used in high-temperature smelting processes. This standard helps to verify their durability in special environments.

3. JIS (Japanese Industrial Standards)

JIS H 4100 —Technical requirements for molybdenum and molybdenum alloys: This standard applies to the production of molybdenum and molybdenum alloys, involving material requirements, chemical composition, mechanical properties, etc. of molybdenum crucibles.

JIS H 4020 —Production technical specifications for molybdenum alloys: In the manufacturing process of molybdenum crucibles, the chemical composition and physical properties of molybdenum alloys can be based on this standard.

4. DIN (German Industrial Standard)

DIN 17558 — Technical requirements for molybdenum and molybdenum alloys: Molybdenum and molybdenum alloy materials used in the production of molybdenum crucibles must comply with this standard to ensure their stability under high temperature and special environment.

DIN 508 – Technical requirements for smelting and casting of molybdenum crucibles: This standard describes in detail the smelting process, casting requirements and related quality standards for the production of molybdenum crucibles.

5. GB (Chinese National Standard)

GB/T 16039-2019 —Technical requirements for molybdenum and molybdenum alloys: This standard involves the production requirements of molybdenum and molybdenum alloys and is applicable to the selection of raw materials for molybdenum crucibles.

GB/T 1959-2017 —Technical requirements for molybdenum alloys: Detailed provisions on the chemical composition, mechanical properties, etc. of molybdenum alloys are made. The production of molybdenum crucibles can refer to this standard.

GB/T 17485-2009 — Technical requirements for molybdenum crucibles: This standard specifically for molybdenum crucibles specifies the requirements for dimensions, tolerances, surface quality, etc. to ensure the quality of the crucibles.

6. CE certification (EU market certification)

molybdenum crucibles want to enter the EU market, they may need to comply with the EU’s basic requirements for safety, health and environmental protection and obtain CE mark certification. These requirements usually cover product safety, environmental impact and health risks during use.

7. RoHS certification (Restriction of Hazardous Substances)

RoHS certification mainly involves electronic and electrical products, but if the molybdenum crucible is used in the electronics industry or other related fields, it may also need to comply with RoHS standards to ensure that it does not contain harmful substances (such as lead, mercury, etc.).

8. REACH certification (Registration, Evaluation, Authorization and Restriction of Chemicals)

molybdenum crucibles may involve molybdenum alloys, coatings or other chemicals, so it may also be necessary to comply with REACH regulations to ensure that the chemicals used in its production process meet the health and environmental requirements of the EU.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

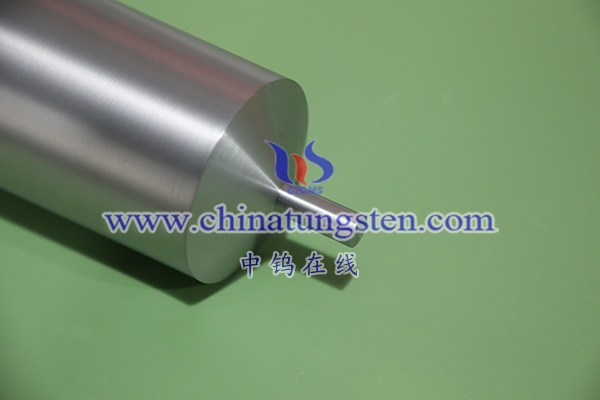

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595