Molybdenum crucibles can be produced by mold opening in some cases, especially when producing large quantities of standardized crucibles. Mold opening production is mainly suitable for the casting process of molybdenum crucibles. Its advantage is that it can improve production efficiency and consistency. The following are some key points for the mold opening production of molybdenum crucibles:

1. Mold manufacturing

The first step in mold production is to design and manufacture the mold. The mold of the molybdenum crucible is usually made of high temperature resistant and corrosion resistant materials, such as quartz sand mold or cast stone mold. These molds can withstand high temperatures and have high precision.

2. Casting process

In mold production, the molybdenum material needs to be melted first, and then the molten molybdenum metal is poured into the prefabricated mold. After the molybdenum metal cools and solidifies, the mold is removed to obtain the basic shape of the molybdenum crucible. Cast molybdenum crucibles usually have high dimensional accuracy, but further processing may be required for detail processing.

3. Advantages

Mass production: Efficient mass production can be achieved through mold production, reducing the production cost of a single crucible.

Dimensional consistency: Open mold production helps ensure that the shape and size of each molybdenum crucible are consistent to meet quality control requirements.

molybdenum crucibles with special shapes or complex designs, the mold can provide higher precision and design flexibility.

4. Disadvantages

High initial cost: The initial cost of making a mold is high, especially for precision molds, so this production method is more suitable for mass production.

Not suitable for small batch production: For small batches or customized molybdenum crucibles, mold production may not be economical because of the long mold making cost and production time.

5. Applicable situations

Molybdenum crucibles produced by mold opening are usually suitable for the following situations:

Production of standardized crucibles in large quantities.

Crucibles that require high precision and shape consistency.

Standard crucibles for special applications such as metallurgy, electronics or semiconductor industries.

6. Subsequent processing

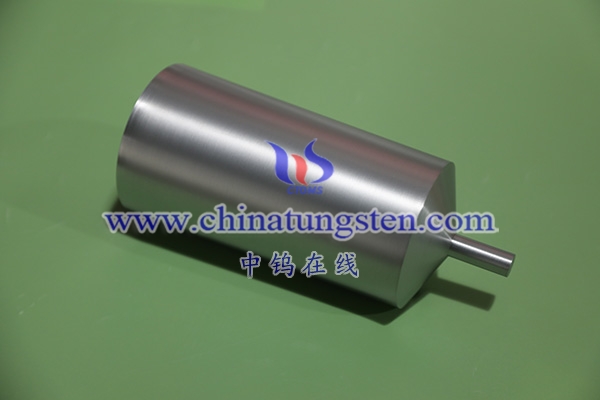

The molybdenum crucible produced by mold opening may need to undergo further subsequent processing steps, such as finishing, surface polishing, welding, annealing, etc., to achieve higher usage requirements and precision.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595