In the process of purchasing molybdenum crucibles, controlling product consistency requires establishing a full-process control system from five dimensions: supplier selection, technical specifications, quality inspection, process monitoring, and data management. The following are specific implementation strategies:

1. Supplier selection and qualification review

Supplier tier management

Priority will be given to suppliers with ISO 9001 quality management system certification and special metal material production qualifications.

Suppliers are required to provide production capacity data for the past three years to ensure that they have the ability to stably supply more than 1,000 pieces in a single batch.

2. Technical specifications and drawing standardization

Clarify technical parameters

The contract stipulates key indicators such as purity (≥99.95%), density (≥9.8 g/cm³), and dimensional tolerance (± 0.1mm) of the molybdenum crucible.

Drawing version control

Use CAD drawings for three-dimensional modeling, mark key dimensions and tolerance zones, and ensure that suppliers produce according to the drawings.

Tool recommendation: Use SolidWorks or AutoCAD to manage drawing versions to avoid production deviations due to drawing updates.

3. Quality Inspection and Acceptance Standards

Raw material testing

Suppliers are required to provide chemical composition reports for each batch of molybdenum plates, and to detect molybdenum content and impurity elements by ICP -OES or XRF.

Finished product testing

Appearance inspection: Use a three-coordinate measuring machine to inspect the dimensional accuracy. The surface roughness must be ≤ Ra1.6 μm.

Performance testing: High temperature oxidation test (1200℃/ 100h) and thermal shock test (2000℃→room temperature cycle 10 times) are carried out to ensure performance consistency.

Tool recommendation: Use ZEISS three-coordinate measuring machine and Netzsch thermal analyzer for testing.

4. Process monitoring and data traceability

Production process monitoring

Suppliers are required to provide key process records (such as sintering temperature, pressure, and time) to ensure stable process parameters.

Batch management and traceability

Use batch number + QR code to identify each product and record information such as raw material batch, production team, and test data.

Tool recommendation: Use SAP ERP or MES system to achieve full-process data traceability.

======================================================================

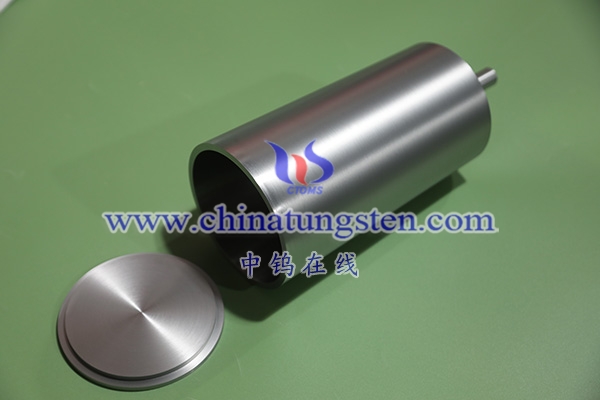

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595