Purchasing molybdenum crucibles, providing detailed technical parameters can ensure that the purchased crucibles meet the expected usage requirements and avoid performance problems caused by inappropriate products. The following are some common and key technical parameters that are usually required to be submitted when purchasing:

1. Material requirements

Purity of molybdenum: The purity of molybdenum crucibles is usually required to be higher, and the purity of molybdenum is generally required to be indicated (such as 99.95%, 99.9%, etc.).

Alloy composition (if it is a molybdenum alloy): If a molybdenum alloy is used, the specific composition of the alloy needs to be clarified (such as alloys containing elements such as titanium and hafnium).

2. Size requirements

Diameter, depth and height: The size of the molybdenum crucible needs to be provided according to the use requirements, especially the internal and external dimensions to ensure that the required melting or experimental materials can be accommodated.

Volume: Volume is usually expressed in liters (L) or cubic centimeters (cm³).

Wall thickness: The thickness of the crucible wall is usually selected based on the high temperature tolerance.

3. Temperature requirements

Maximum working temperature: clarify the maximum working temperature that the molybdenum crucible can withstand (generally up to about 3000°C) to ensure the stability of the crucible at high temperatures.

Heating rate requirements: Some applications require controlled heating rate, and the appropriate heating rate range can be specified during purchase.

4. Surface treatment requirements

Surface finish: Surface finish requirements such as whether polishing is required or surface roughness grade (such as Ra value) to meet different experimental or production needs.

Oxidation protection treatment: whether surface oxidation protection treatment is needed, such as coating, molybdenum reprocessing, etc., to improve its antioxidant capacity.

5. Corrosion resistance requirements

High temperature oxidation resistance: Molybdenum crucibles are easily oxidized at high temperatures, so it is necessary to clarify their ability to withstand oxidizing atmospheres.

Chemical corrosion resistance: Depending on the type of material used and the experimental conditions, it may be necessary to consider the crucible’s resistance to chemical corrosion, such as its adaptability to acidic or alkaline environments.

6. Structure and shape requirements

Bottom shape: whether a flat bottom, round bottom or other special shape is required, the bottom design directly affects the heat conduction effect and the stability of the crucible.

Shape design: Is special shape design required, such as reinforcing ribs or supporting structures, to enhance the crucible’s carrying capacity?

7. Mechanical properties

Hardness requirements: For some special application scenarios, it may be necessary to specify the hardness requirements of the crucible to improve its ability to resist pressure and damage.

Thermal shock resistance: Whether it needs to have good thermal shock resistance to adapt to rapid temperature changes.

8. Environmental requirements

Atmosphere requirements: whether the crucible needs to be used in a specific atmosphere during operation, such as an inert atmosphere, vacuum, or a specific gas environment (such as hydrogen, nitrogen, etc.).

Radiation Environment: If used in a special radiation environment, radiation stability or specific thermal conductivity properties may be required.

9. Production process requirements

Production process requirements: whether specific production processes are required, such as casting, forging, welding, etc.

Surface treatment process: whether additional surface treatment processes are required, such as plating, coating, etc., to prevent oxidation and corrosion.

10. Quality Standards

Testing standards: whether a third-party test report is required, or whether it complies with certain international or domestic standards, such as ISO, ASTM, GB, etc.

Defect tolerance: Are there any tolerance requirements for surface defects, pores, cracks, etc.

11. Durability and service life

Use cycle requirements: Are there expected service life requirements, such as how many use cycles or operation frequencies the molybdenum crucible is expected to withstand?

Reusability: Is it necessary to confirm the reusability of the crucible, especially in high temperature and harsh environments?

12. Packaging and Shipping Requirements

it is not damaged during transportation.

Transportation conditions: Are there any requirements for environmental conditions such as transportation temperature and humidity?

======================================================================

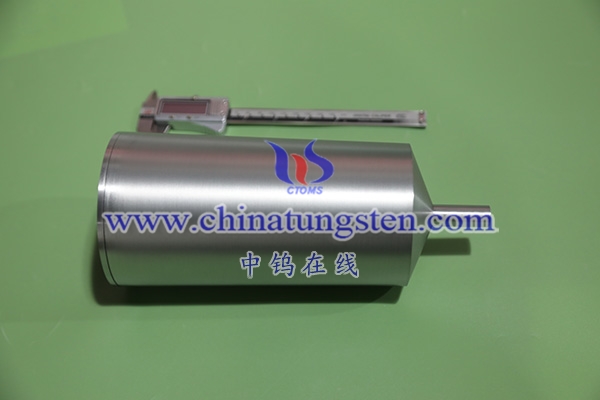

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595