This is a very cutting-edge and practical question. Molybdenum crucibles have long been used in high-end processes such as high-temperature smelting and crystal growth due to their excellent high-temperature performance, good thermal conductivity and high chemical resistance. However, with the development of materials science, there is indeed a trend that some new materials will partially replace molybdenum crucibles in specific application scenarios. The following are some possible alternative materials and their applicability comparison:

1. New materials that can replace molybdenum crucibles

1. Tantalum (Ta) crucible

Advantages: melting point is as high as 3017°C, stronger oxidation resistance than molybdenum, more stable at high temperature;

Application: Widely used in high temperature reactions and preparation of ultra-high purity materials;

Disadvantages: extremely high cost, difficult to process, easy to absorb gas (hydrogen, oxygen);

Substitutability: It is superior to molybdenum in ultra-high temperature and strong corrosion environment, but its economic efficiency is poor.

2. Tungsten (W) crucible

Advantages: Melting point is as high as 3420°C, the highest among all metals;

Application: Ultra-high temperature crystal growth (such as sapphire, lithium tantalate);

Disadvantages: high brittleness, poor stability in oxidizing environment;

molybdenum at extremely high temperatures, but still requires a protective gas in an oxidizing atmosphere.

3. Boron nitride crucible (BN crucible)

Advantages: strong insulation, good thermal stability, no adhesion to molten metal;

Application: vacuum melting, glass material processing;

Disadvantages: low mechanical strength and poor impact resistance;

Substitution: It can replace molybdenum in some non-metallic melts or high-purity processes.

4. Alumina/zirconia/yttria ceramic crucible

Advantages: can withstand high temperatures above 2000°C, anti-oxidation, non-conductive;

Application: sintering of ceramics, glass, and metal oxides;

Disadvantages: high brittleness, poor thermal shock stability, and poor thermal conductivity;

Alternative: Used in oxidizing atmospheres or environments requiring insulation. It can replace molybdenum but cannot withstand rapid thermal shock.

5. SiC (Silicon Carbide), ZrB₂ / SiC Composites

Advantages: Excellent corrosion resistance and thermal shock resistance, high thermal conductivity;

Applications: aerospace, carbide manufacturing, molten metal contact;

Disadvantages: difficult to manufacture and expensive;

Substitutability: It is a potential molybdenum substitute material under high thermal shock and corrosion resistance requirements.

6. Coated/composite molybdenum crucible

Such as molybdenum -based composite crucible: the outer layer is coated with anti-oxidation ceramics such as alumina and silicon nitride;

It can extend the service life in an oxidizing atmosphere. It does not completely replace molybdenum, but it broadens its application.

2. Reasons why molybdenum crucibles cannot be easily replaced

Despite the existence of the above materials, molybdenum crucibles still have irreplaceable advantages in many aspects:

Relatively good machinability (easily machined among metals);

Costs are relatively manageable in high-temperature materials;

Long-term stability in inert atmosphere or vacuum;

High performance adjustability (can be optimized through alloying, coating, etc.);

======================================================================

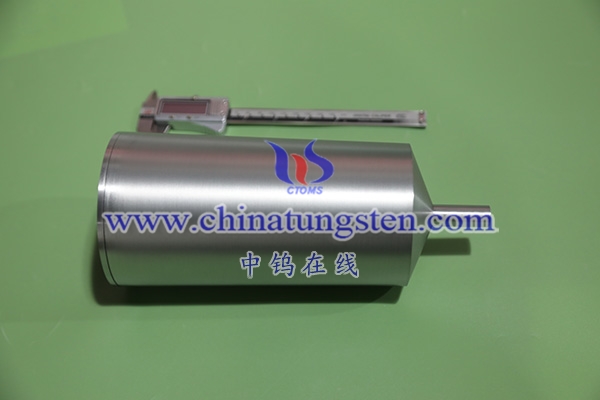

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595