Molybdenum crucibles have shown significant advantages under the concept of “Green Manufacturing”, especially in terms of resource conservation, environmental friendliness, energy efficiency optimization and recycling, which are in line with the direction of sustainable industrial development. The following is a detailed analysis of its main advantages in green manufacturing from multiple perspectives:

1. Sustainability of the material itself and low environmental impact

1. High melting point, high stability, reducing replacement frequency

Molybdenum has a melting point of up to 2620°C, and has excellent thermal stability and corrosion resistance, with a service life far exceeding that of most metal crucibles;

Due to its excellent high temperature resistance, molybdenum crucibles can work stably for a long time in harsh environments, reducing resource waste and pollution emissions caused by frequent replacement.

2. Highly recyclable

Scrapped molybdenum crucibles can be recycled into recycled molybdenum products through smelting, crushing, re-sintering and other processes;

The recycling rate can be as high as over 90%, significantly reducing the demand for resource extraction and conforming to the concept of circular economy.

2. Assisting efficient and clean production processes

1. Can be used for clean melting in vacuum and high purity atmosphere

Molybdenum crucibles are widely used in vacuum metallurgy, electronic ceramic sintering, semiconductor material purification and other high-cleanliness environments;

Avoid the precipitation of impurities in traditional crucibles such as graphite and quartz to contaminate process materials, ensure product purity and improve yield rate.

2. Use energy-saving equipment to reduce energy consumption

Molybdenum has excellent thermal conductivity (thermal conductivity is about 138 W/m·K), fast temperature rise response and high heat conduction efficiency;

Adapting to modern induction heating, microwave sintering and other high-efficiency green heating methods helps to reduce energy consumption and carbon emissions.

3. Adapting green material technology to help the environmental protection industry

1. Used for the preparation of new environmentally friendly materials

Widely used in:

Sapphire crystal growth (for high-efficiency LED lighting);

OLED evaporation process (green display technology);

Sintering of solar cell materials;

Preparation of carbide/nitride ceramics (such as SiC and BN, used in energy-efficient equipment and environmental management).

2. Does not react with most functional materials

Molybdenum is highly chemically inert in a neutral or reducing atmosphere and does not react with the melt, thus reducing by-product emissions;

It can be used in low-pollution production scenarios such as inorganic salts, glass, and metal oxides.

4. High compatibility of green manufacturing chain

1. Applicable to powder metallurgy process

Molybdenum crucibles can be used in green forming technologies such as near-net forming and additive manufacturing (3D printing);

It is highly compatible with low scrap rate and low energy consumption manufacturing systems.

2. Easy to use for intelligent and automated control

High-precision geometry and thermal stability make it more suitable for integration into intelligent equipment, automatic heating systems, and precision temperature control equipment;

Promote the industry to upgrade to intelligent manufacturing and green intelligent manufacturing.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

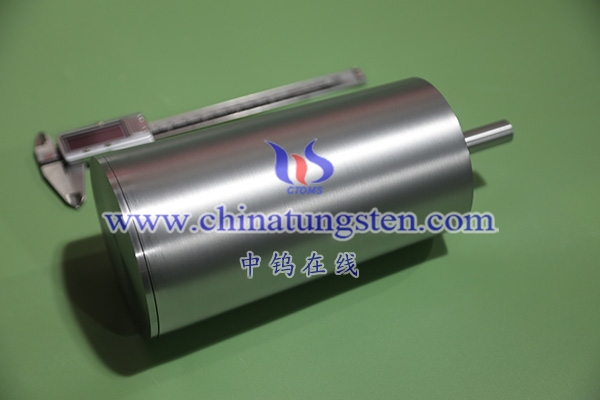

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595