At present, the technology of 3D printing molybdenum crucibles is gradually developing and has been initially applied in scientific research and special industries. However, due to the high melting point and high activity of molybdenum, this process still has a high technical threshold and cost.

1. Feasible technical route for 3D printing molybdenum crucible

1. Selective Laser Melting (SLM)

Principle: Use high-power laser to melt molybdenum metal powder layer by layer;

advantage:

Can realize complex shape design;

High precision and good density;

Suitable for customized crucible structures (such as micro grooves, internal threads);

difficulty:

The laser power requirement is extremely high (the melting point of molybdenum is 2623°C);

Oxidation sensitive, need to be carried out in a high-purity inert atmosphere or vacuum;

Molybdenum powder preparation and sphericity control are difficult;

The residual stress is large and requires subsequent heat treatment.

2. Electron Beam Melting (EBM)

Principle: Use electron beam to melt metal powder in vacuum;

advantage:

Very suitable for high melting point metals such as molybdenum;

It can avoid oxidation;

Dense molding and small deformation;

shortcoming:

The cost is extremely high;

The forming speed is slow;

Suitable for high-end customization in scientific research or aerospace.

3. Binder Jetting/Slurry Printing + Sintering

method:

the molybdenum powder is printed and formed with a binder or slurry;

Then it is sintered at high temperature to form a dense structure;

Advantages:

Low cost and strong scalability;

Suitable for batch production of small and medium-sized crucibles;

Limitations:

The sintering process easily produces pores;

Mechanical properties are inferior to SLM /EBM processes;

Dimensional shrinkage needs to be precisely controlled.

2. Current application status of 3D printed molybdenum crucibles

Research institutions: Germany’s Fraunhofer and the United States’ ORNL have conducted 3D printing research on molybdenum and refractory metals;

Aerospace: Try to customize molybdenum components in some high-temperature turbine parts, nozzles, and heat exchangers;

Customized crystal equipment parts: A small number of crystal equipment manufacturers have tried 3D printing molybdenum heat field components or crucible supports;

However, a mass industrialized production chain has not yet been formed.

3. Prospects and Challenges of 3D Printed Molybdenum Crucibles

| aspect | Advantages | challenge |

| Design freedom | It is possible to construct structures that are difficult to achieve with traditional techniques | Modeling needs to take thermal stress and deformation into account |

| Manufacturing efficiency | Rapid prototyping and small batches have obvious advantages | High cost and narrow process window |

| Application prospects | High-end customization and scientific research experiments are extremely valuable | It is not yet capable of replacing traditional manufacturing on a large scale |

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

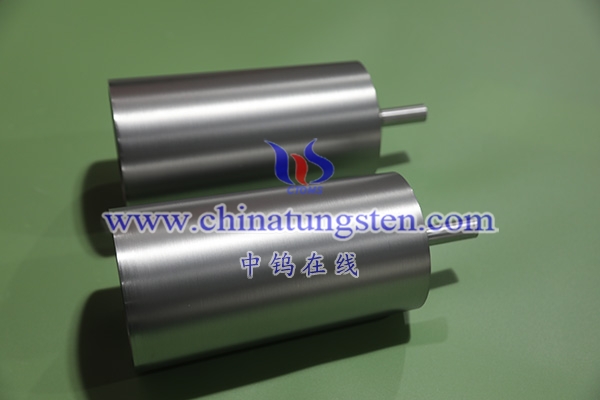

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595