Coating technology can significantly improve the service life and performance of molybdenum crucibles in harsh environments such as high temperature, oxidation, and corrosion. Below we introduce in detail several common molybdenum crucible surface coating methods and the performance improvements they bring.

1. The main function of coating

Anti-oxidation protection: Molybdenum is easily oxidized above 800℃ in air, forming MoO₃ volatilization loss. The coating can isolate oxygen from contact.

Enhanced corrosion resistance: acts as a shield in molten salt, alkali metal or certain active metal environments.

Heat reflection/insulation: Reduces heat loss or thermal stress damage.

Improve surface finish: Improve material release, melting, cleaning and other performance.

Anti-adhesion performance: avoid raw materials from reacting or adhering to the molybdenum crucible.

Enhance mechanical stability and thermal fatigue life.

2. Common coating types and performance improvements

1. Alumina (Al₂O₃) coating

Function: Anti-oxidation and anti-corrosion;

Applicable to: heating in air atmosphere, molten salt experiment;

Preparation methods: thermal spraying, sol-gel, plasma spraying, etc.

2. Silicide coating (such as MoSi₂, WSi₂)

SiO₂) at high temperature;

Advantages: Suitable for long-term operation above 1500℃;

Applicable scenarios: single crystal furnace thermal field, sapphire crystal growth, etc.

3. Boron nitride (BN) coating

Function: Excellent anti-adhesion and lubricity;

Commonly used in: glass melting, ceramic preparation, metal powder sintering;

Advantages: Isolate material reactions and prevent sticking to the wall.

4. Silicon Carbide (SiC) or Carbon Coating

Function: Improve thermal shock stability and thermal conductivity;

Note: Use under reducing or inert atmosphere to avoid oxidation.

5. Zirconium-based ceramic coating (such as ZrO₂)

Function: high temperature stability, heat insulation, and prevention of thermal corrosion;

Applications: aerospace thermal barriers, alkali metal smelting, etc.

3. Coating method (process)

| Coating method | Features | Applications |

| Thermal Spraying | Fast film formation and adjustable thickness | Industrial mass application |

| Sol-Gel Method | Low cost, high density | Laboratory or precision equipment |

| Vacuum evaporation/magnetron sputtering | Uniform film and strong adhesion | Microelectronics, precision field |

| Chemical Vapor Deposition (CVD) | Dense film, high temperature resistance | High-end devices and special applications |

4. Selection Suggestions

High temperature oxidation resistance: MoSi ₂ and Al ₂ O ₃ are preferred;

Glass melt or alkaline material: BN or ZrO₂ is recommended;

Avoid material reactions or contamination: choose inert ceramic coatings;

Special electrical/optical scenarios: composite coatings or functional films can be used;

Ultra-high temperature or vacuum environment: CVD or EB-PVD deposition is recommended.

5. Notes

The coating must not significantly reduce the thermal conductivity or mechanical strength of the crucible;

The coating should match the thermal expansion coefficient of the molybdenum substrate to avoid thermal cracking;

The coating treatment should take into account the subsequent use atmosphere of the crucible (oxidizing vs reducing);

The coating should avoid falling off or peeling and require good adhesion.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

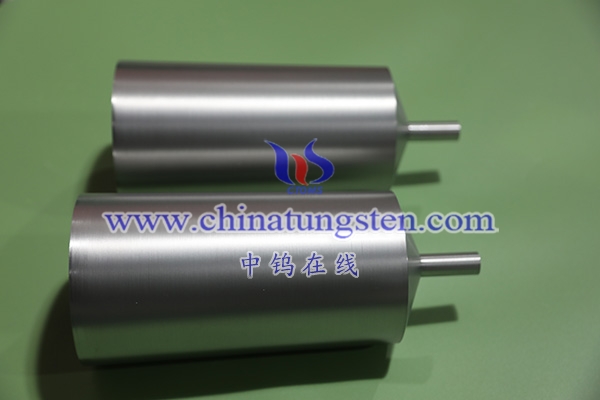

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595