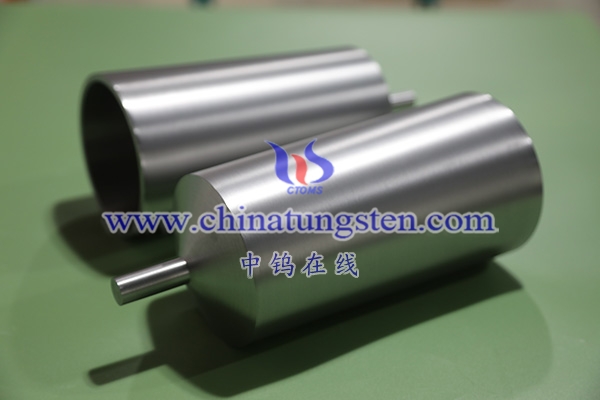

Molybdenum crucibles to a certain extent, especially in the following aspects. The following is a detailed analysis:

molybdenum crucible by nanostructure

1. Grain Refinement Strengthening

nanocrystalline molybdenum or ultrafine-crystalline molybdenum increases, effectively hindering grain boundary sliding and crack propagation;

It exhibits better thermal fatigue resistance and dimensional stability under high temperature conditions.

2. Inhibit high temperature grain growth

Traditional molybdenum tends to coarsen grains at high temperatures, which reduces strength;

Nanostructures have a stronger grain pinning effect due to higher grain boundary energy, which slows down the grain growth process;

Especially under **repeated thermal cycling** conditions, the stability is significantly improved.

3. Thermal stress dispersion mechanism

substructures in the nanostructures helps to relieve local thermal stress concentration;

Improve overall thermal shock resistance and crack resistance.

4. Improve oxide layer adhesion

Surface nano- treatment can increase the bonding strength with the anti-oxidation coating;

The coating is less likely to fall off, which improves the anti-oxidation stability and thermal isolation effect.

2. Related preparation technology

1. Nanostructured PM-Mo

The crucible is formed by pressing and sintering nano-molybdenum powder, and the grain size can be controlled at the level of hundreds of nanometers;

It is mostly used in high-end crystal growth, high-temperature heat source and other occasions;

However, the cost is high and the processing is difficult.

2. Surface nano- treatment

For example, laser shock strengthening (LSP), high-energy ball milling + hot pressing sintering, plasma spraying fine-grained coating;

Form a nanostructured surface layer to improve surface thermal stability and corrosion resistance.

3. Nanocomposite reinforcement materials

nano carbides and nitrides (such as TiC, ZrC, Si₃N₄) to the molybdenum matrix;

Forming a molybdenum -based nanocomposite crucible that combines strength, thermal conductivity, and heat resistance;

Can effectively inhibit crack initiation and propagation.

3. Application Prospects and Challenges

| Advantages | challenge |

| Significantly improved thermal stability | The preparation process is complicated and the cost is high |

| Stronger thermal shock resistance | Nanopowders are highly oxidizing and require an inert environment for preparation |

| Can be used with high performance coatings | Smaller grain size may sacrifice some high temperature creep resistance |

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595