Optimizing the thermal stress distribution of molybdenum crucibles is a key measure to extend their service life, improve thermal stability and prevent cracking failure. The following are system optimization strategies from multiple perspectives of design, materials, processes and usage conditions:

1. Structural design optimization

1. Uniform wall thickness design

Uneven wall thickness can lead to uneven temperature gradients, which can create stress concentrations;

Optimize wall thickness to within **±5%** to avoid hot or cold spots.

2. Rounded corner transition structure

A large rounded corner (≥ R5 mm) is used at the junction of the bottom and the side wall to avoid thermal stress concentration caused by sharp corners;

Effectively reduce the probability of crack source formation.

3. Conical or spherical bottom design

For situations that require high heat flux density (such as crystal growth), using a slightly tapered or spherical bottom can reduce heat flux concentration and improve structural stability.

2. Material and Organization Control

1. Fine grain structure

Fine-grained structures (especially submicron or nanometer grains) can disperse thermal stress more evenly;

materials prepared by hot isostatic pressing (HIP) sintering or high-energy ball milling.

2. High purity materials

Impurities such as Fe, Si, and O can cause grain boundary embrittlement and reduce thermal stability;

TZM alloy or high-purity molybdenum material with a purity of ≥99.95% is preferred.

3. Manufacturing and heat treatment process

1. Annealing

**Vacuum annealing (1800~2000℃)** is used to eliminate cold working stress;

After annealing, the grains are stable, which is conducive to the release of thermal stress.

2. Multiple intermediate annealing + equal diameter deformation

During the spinning or forging process, adding multiple intermediate annealing can improve stress uniformity;

Control the balance of overall stress field distribution to avoid local hardening and crack initiation.

4. Temperature control and working condition adaptation

1. Slowly increase the temperature

It is recommended to control the heating rate to ≤5~10 ℃/min, especially in the temperature range of 200℃~600℃;

Avoid stress cracks caused by uneven thermal expansion.

2. Set the warm-up phase

Add a slow-rise interval before high-temperature operation (e.g., maintain the temperature at 300-400°C for 30-60 min);

Allow the entire crucible to be heated evenly to reduce thermal stress concentration.

3. Symmetry of working conditions

Ensure that the heating method (such as resistance heating, induction heating) is arranged symmetrically;

If a graphite heating element is used, it can be supplemented with a ceramic insulation tube or a thermally conductive filler to improve the uniformity of the temperature field.

5. Advanced technical means

1. Finite element simulation (FEA) thermal stress simulation

to predict temperature and stress fields during the design phase;

Helps to identify areas of stress concentration and optimize the structure.

2. Surface strengthening treatment

laser cladding, PVD coating (such as ZrO₂, Y₂O₃) and other processes can slow down the thermal conduction gradient;

Improve surface heat resistance and heat flow distribution.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

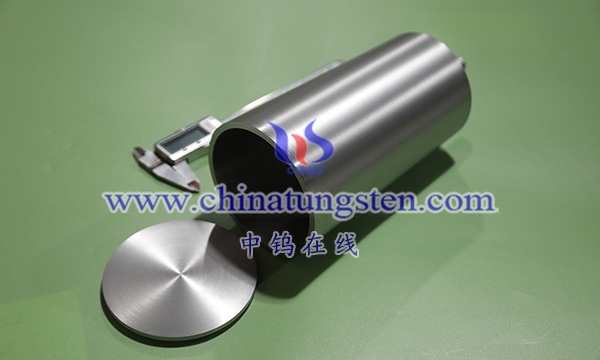

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595