Molybdenum crucibles can be used in the field of nuclear energy material processing, and they have irreplaceable advantages in some key links. The following is a detailed analysis of molybdenum crucibles used in nuclear energy material processing:

1. Basis of nuclear applicability of molybdenum materials

1. High melting point, excellent thermal stability

Molybdenum has a melting point of up to 2620°C and can work stably for a long time in the high-temperature processing environment of nuclear energy systems (such as smelting of metals such as uranium and thorium or sintering of fuel).

2. Good neutron performance

Molybdenum has a low thermal neutron absorption cross-section (about 2.7 barns) and does not significantly interfere with neutron flux or neutron economy, making it particularly suitable for use in non-fuel structural components or containers.

3. Excellent radiation resistance

It is not prone to embrittlement or significant expansion under neutron irradiation and can withstand the effects of exposure to nuclear reactors and radioactive environments for a long time.

2. Application scenarios of molybdenum crucibles in nuclear material processing

1. Smelting and purification of metals such as uranium and thorium

Molybdenum crucibles are used for uranium metal reduction, distillation purification, alloying and other processes under high temperature conditions;

Molybdenum does not easily react with molten metals and can effectively maintain the high purity of fuel materials.

2. High temperature sintering of fuel particles

nuclear fuel particles (such as UO₂, PuO₂, MOX fuel) are sintered in a hydrogen or argon atmosphere, the molybdenum crucible can provide a high-temperature, high-cleanliness, and non-reactive pollution working environment.

3. High temperature containers in nuclear waste treatment

When processing nuclear waste (such as converting high-level radioactive waste into ceramic/glass state), molybdenum crucible can be used as a high-temperature sintering or melting reaction vessel;

It is beneficial to improve processing efficiency and reduce residue.

Precautions

It must be used in an inert atmosphere or vacuum: Molybdenum is easily oxidized at high temperatures, and nuclear fuel processing is generally carried out in a reducing or vacuum environment, so it has good adaptability.

molybdenum at high temperatures and damage the crucible.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

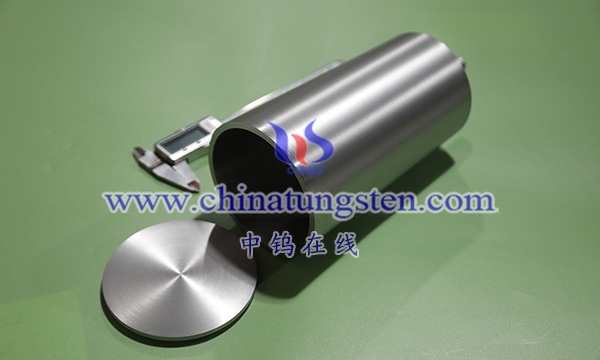

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595