Many universities in China are actively carrying out research projects related to molybdenum crucibles, especially focusing on the fields of high-temperature material preparation, nuclear energy material processing, crystal growth, etc. The following are some representative research directions and project examples:

1. High temperature materials and crystal growth research

Molybdenum crucibles are widely used in crystal growth and high-temperature alloy smelting due to their excellent high-temperature performance. Domestic universities have conducted relevant research in the following areas:

Crystal growth process optimization: Research on thermal field design and temperature control of molybdenum crucibles during the growth of sapphire, silicon carbide and other crystals to improve crystal quality and growth efficiency.

High temperature alloy melting: Explore the application of molybdenum crucible in high temperature alloy melting and study its effect on the uniformity and purity of alloy composition.

2. Nuclear material processing and radioactive waste management

molybdenum crucibles in nuclear energy material processing have also attracted attention. Related research includes:

Nuclear fuel preparation: Study the stability and material compatibility of molybdenum crucibles in the preparation of uranium, thorium and other nuclear fuels.

Radioactive waste treatment: Explore the application of molybdenum crucibles in high-level liquid waste solidification and radioactive waste melting treatment, and evaluate their corrosion resistance and service life.

3. Material surface modification and performance improvement

In order to improve the performance of molybdenum crucibles, domestic universities are also conducting research in the following areas:

Surface coating technology: Develop anti-oxidation and corrosion-resistant coating materials to extend the service life of molybdenum crucibles.

Nanostructure design: Study the effect of nanostructure on the thermal stability and mechanical properties of molybdenum crucibles and optimize their microstructure.

======================================================================

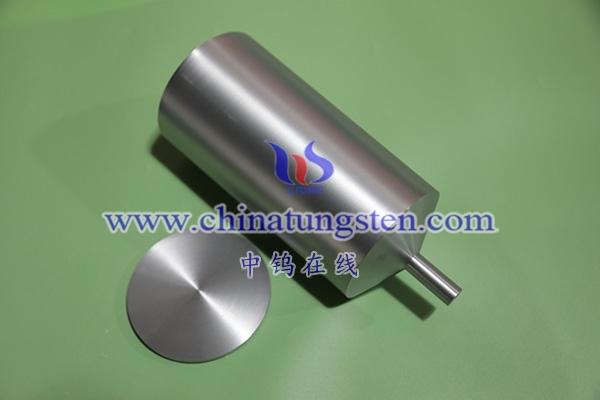

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595