Molybdenum crucibles play an important role in the sustainable utilization of scarce resources, especially in the research and application of high-temperature materials, rare metal smelting, and advanced manufacturing technologies. The following are several main aspects that explain the role of molybdenum crucibles in the sustainable utilization of scarce resources:

1. Rare metal refining and recycling

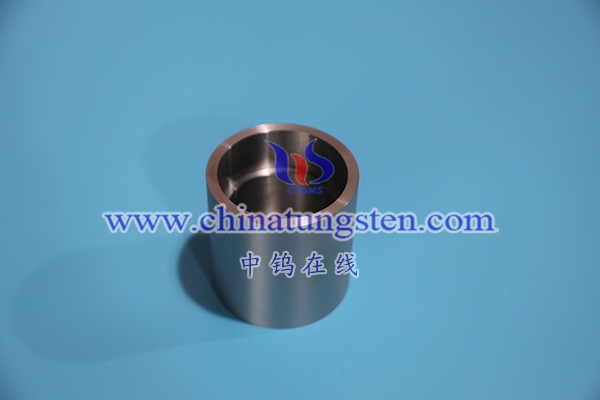

Molybdenum crucibles are widely used in the extraction and refining of rare metals. Especially in the smelting process of high-value metals such as tungsten, platinum, gold, and silver, molybdenum crucibles provide a stable and high-temperature resistant environment for high-temperature reactions.

Key role:

Improve recycling efficiency: In the refining process of rare metals, molybdenum crucibles can withstand high-temperature smelting and help the stratification of metal solutions, so that high-value metals can be extracted efficiently.

Reduce loss: By using molybdenum crucibles, the oxidation or volatilization loss of metals can be reduced, thereby increasing the recovery rate of materials.

Influence:

Reduce resource waste: Molybdenum crucibles can ensure the purity and quality of metals during the smelting process, so that precious metals can be recycled and utilized to the greatest extent, reducing the demand for raw ore resources.

2. Refining of rare earth materials and scarce resources

Molybdenum crucibles are not only used in metal smelting, but also play a role in the refining and purification of rare earth materials and other scarce resources. Rare earth elements (such as neodymium, lanthanum, cerium, etc.) are increasingly used, especially in the fields of new energy, electronic devices, magnetic materials, etc., and the refining of these rare elements often needs to be carried out in a high temperature environment.

Key role:

Support high temperature refining: Molybdenum crucible can work stably in high temperature environment, ensuring that the refining process of rare earth metals is not affected by temperature fluctuations.

Reduce environmental pollution: Efficient molybdenum crucible design and use help reduce harmful gas emissions during the smelting process and meet green manufacturing requirements.

3. Sustainable development and circular economy

molybdenum crucibles give them unique advantages in the circular economy. Especially when it comes to metal recycling, waste treatment and metal composite material production, the durability of molybdenum crucibles can greatly reduce the waste of resources and promote the secondary use of metals.

Key role:

Improve metal recycling rate: The stability of molybdenum crucibles allows waste metals to be converted into usable resources through the smelting process during metal recycling, reducing the demand for new resources.

Support recycling: Molybdenum crucibles are designed to be used multiple times in some high-end manufacturing, especially in high-temperature alloy smelting. This reuse not only reduces dependence on raw materials, but also reduces production costs.

4. Environmentally friendly high temperature materials

With the improvement of global environmental awareness, molybdenum crucible, as a high-temperature resistant material, is often used in environmental protection technologies, such as waste incineration, hazardous waste treatment and other fields. In these scenarios, molybdenum crucibles can help effectively reduce the release of harmful substances and promote the safe treatment and resource recovery of hazardous waste.

Key role:

Efficient waste treatment: In the process of waste treatment, molybdenum crucibles can help decompose toxic and harmful substances at high temperatures, reduce their environmental impact, and comply with the concept of sustainable development.

Improve environmental efficiency: The high temperature stability and corrosion resistance of molybdenum crucibles make these processes safer and more reliable, and reduce environmental pollution.

5. Innovative materials and scarce resource substitution

With the continuous development of technology, molybdenum crucibles are also being used in the research and development of new alloys and alternative materials. These new materials are usually used to replace rare metals or reduce the use of rare metals. Molybdenum crucibles play an important role in this process, especially in the fields of high-temperature alloys and superconducting materials.

Key role:

Support the research and development of new materials: Molybdenum crucibles provide the necessary high-temperature testing environment in the research and development of new alloys and alternative materials, helping researchers develop more environmentally friendly and efficient materials.

Reduce dependence on scarce resources: The use of molybdenum crucibles can promote the efficient production and application of these alternative materials and promote sustainable material innovation.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595