Compared with the recycling system of other metal materials, the recycling system of molybdenum crucible does have some challenges, but it is also constantly improving. Since molybdenum itself is a relatively scarce and high-value metal, especially widely used in high-temperature environments, recycling and reuse are particularly important. The following are some key points about the recycling system of molybdenum crucible:

1. Recycling channels are not fully popularized

At present, the recycling system of molybdenum crucibles is not as perfect as that of some common metals (such as aluminum, copper, and steel). Although molybdenum crucibles play an important role in some high-tech applications, the recycling channels and equipment are relatively limited, especially in some small or professional laboratories and factories, the recycling rate of molybdenum crucibles is not high.

main reason:

Recycling equipment limitations: Molybdenum crucible recycling usually requires reprocessing during high-temperature smelting, which places high demands on the recycling equipment and requires it to be resistant to high temperatures and corrosion.

High recycling cost: Since the production process of molybdenum crucibles is relatively complicated, the recycling process also consumes a lot of energy and resources, which increases the recycling cost.

2. Molybdenum Recycling Potential

molybdenum itself has a high recycling value, so the recycling potential of molybdenum crucibles is considerable. Many companies and scientific research institutions have realized the importance of recycling molybdenum crucibles, especially in industries that require molybdenum crucibles to be used repeatedly, such as crystal growth, high-temperature alloy smelting and other fields.

Recycling method:

Smelting and recycling: The used molybdenum crucible is smelted at high temperature to recover the molybdenum metal. This process requires relatively advanced smelting technology and equipment.

Chemical recovery: The molybdenum crucible is treated by chemical methods, and the molybdenum metal is recovered by solvent extraction or electrolysis.

Continuous use:

Recycling: Recycled molybdenum metal can be used again in the production of molybdenum crucibles, forming a closed loop and promoting the development of the circular economy of molybdenum.

3. Environmental issues and challenges

Molybdenum crucible is not without challenges, especially in terms of environmental protection. During the high-temperature use of molybdenum crucibles, they may react with other metals and gases to produce harmful substances. This requires that the recycling process not only efficiently recovers molybdenum metal, but also requires the treatment of waste gas and waste residue to ensure that there is no pollution to the environment.

Environmental requirements:

Waste gas treatment: The recycling process of molybdenum crucibles may involve the release of some harmful gases. How to effectively collect and treat these waste gases has become a major challenge in the recycling system.

Waste slag management: Some waste slag may be generated during the recycling process of molybdenum crucibles. If these waste slags are not properly handled, they will also have an impact on the environment.

4. Policy support and industry promotion

Molybdenum crucibles to a certain extent. Especially in the fields of metallurgy, electronics, high-end manufacturing, etc., regulations and technical standards to promote the recycling and reuse of molybdenum crucibles are gradually being introduced.

Policy promotion:

Circular economy regulations: Various countries and regions have successively introduced policies and regulations on metal recycling, especially the recycling of scarce metals such as molybdenum, which has been listed as a priority, and government subsidies and technical support have gradually increased.

Corporate responsibility: Some molybdenum crucible manufacturers and users have also strengthened the recycling and reuse of materials in the production process, promoting the green manufacturing of molybdenum crucibles.

5. International cooperation and technological innovation

Molybdenum crucible is likely to be further improved through international cooperation and technological innovation in the future. As the world pays more attention to the recycling of rare metals, the recycling technology of molybdenum crucibles will also be continuously optimized. International cooperation not only helps the introduction of technology, but also promotes the recycling of molybdenum resources worldwide.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

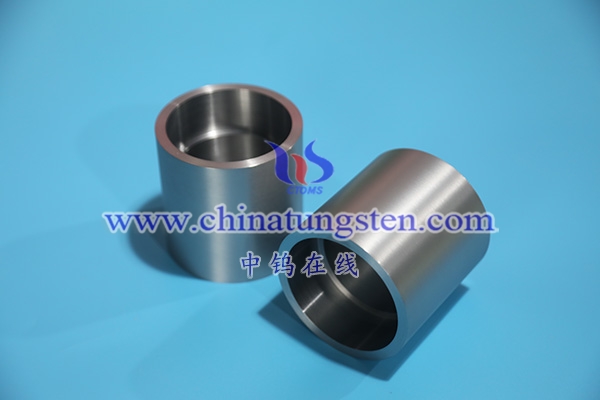

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595