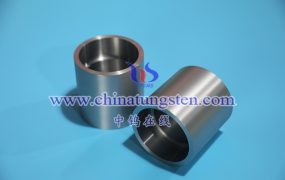

Molybdenum crucible in energy conservation and emission reduction is mainly reflected in its efficient heat conduction, high temperature stability and optimization of high temperature reaction process. In modern manufacturing and scientific research, especially in metal smelting, material preparation, and high temperature applications, the application of molybdenum crucible can significantly improve energy efficiency, reduce energy waste, and reduce the emission of harmful gases. Specifically, the role of molybdenum crucible in energy conservation and emission reduction can be explained from the following aspects:

1. High temperature stability and thermal efficiency

Molybdenum crucible is its excellent high temperature stability, which allows it to work for a long time under extremely high temperature conditions (up to 3000°C) without deformation or damage. This enables it to effectively reduce heat loss, improve heat conduction efficiency, and save energy consumption during the heating process.

Key role:

Reduce energy loss: The excellent thermal conductivity of the molybdenum crucible ensures the concentration and uniform distribution of heat during high-temperature smelting, avoids excessive heat loss, and thus reduces the consumption of additional energy.

Optimize the heating process: Through efficient thermal management, molybdenum crucibles help achieve precise temperature control, making the heating process more efficient and reducing unnecessary energy waste.

2. Improve smelting and melting efficiency

In many metals smelting, alloy melting, and crystal growth applications, molybdenum crucibles play a vital role as containers. Molybdenum crucibles can improve the efficiency of smelting and melting processes, shorten smelting cycles, and reduce energy consumption.

Key role:

Speed up the melting speed: The high temperature resistance and excellent heat conductivity of the molybdenum crucible enable the molten metal to reach the required temperature faster, shorten the heating time, and thus reduce the total energy consumption.

Reduce energy waste: The high heat capacity of the molybdenum crucible can store more heat. When the external temperature changes, it can balance the temperature fluctuations and reduce energy consumption.

3. Promote the application of clean energy

Molybdenum crucibles can support clean energy technologies in the preparation of certain advanced materials, such as in the production of solar cells, hydrogen production and use, etc. Through efficient thermal management, molybdenum crucibles can help these technologies reduce energy consumption and improve overall energy efficiency.

Key role:

Support new energy manufacturing: The application of molybdenum crucibles can help reduce the energy consumption of high-temperature processes required in clean energy production, thereby improving overall energy efficiency.

Supporting energy conversion and storage technologies: For example, in the process of hydrogen production, molybdenum crucibles can promote more efficient catalytic reactions under high temperature conditions and reduce unnecessary energy losses.

4. Reduce emissions and harmful gas release

molybdenum crucibles enable them to effectively avoid the release of harmful gases in high temperature environments, thereby reducing the emission of harmful substances during material preparation and metal smelting.

Key role:

Reduce harmful gas emissions: The chemical stability of molybdenum crucibles can avoid the production of some harmful gases or metal oxides in high temperature environments, which plays a positive role in reducing environmental pollution.

Support green manufacturing: By optimizing the atmosphere and gas control during high temperature treatment, molybdenum crucibles help reduce emissions in industrial processes, in line with the goals of green environmental protection and energy conservation and emission reduction.

5. Extend service life and reduce resource waste

Molybdenum crucibles can be used in multiple cycles due to their strong and durable characteristics, which greatly prolongs the service life of the equipment, thereby reducing the waste of resources caused by frequent equipment replacement during the production process. This is also an important manifestation of energy saving and emission reduction.

Key role:

Improve material utilization: The durability of molybdenum crucibles allows them to be used repeatedly, reducing resource consumption and waste generation, and supporting sustainable manufacturing methods.

Reduce material waste: Compared with other fragile materials, the long life of molybdenum crucibles reduces the waste of raw materials in the production process, further supporting energy conservation and emission reduction.

6. Optimizing industrial production processes

Molybdenum crucibles can help optimize the production process in many industrial productions, such as metal smelting and alloy manufacturing, making it more efficient and environmentally friendly. By using molybdenum crucibles rationally, unnecessary heat energy waste can be reduced, production efficiency can be improved, and the purpose of energy conservation and emission reduction can be achieved.

Key role:

Improve overall production efficiency: The thermal effect of the molybdenum crucible makes the entire production process more stable, thereby improving production efficiency and reducing time and energy waste.

Green process optimization: In some high-temperature processing, the efficient energy utilization of molybdenum crucibles helps optimize the process flow and reduce the consumption of resources and energy.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595