The forming process of tungsten-nickel-iron alloy is the process of converting uniformly mixed powder into a green body with a certain shape and size, aiming to provide a stable structural basis for subsequent sintering. Common forming processes include die pressing, isostatic pressing, injection molding, etc., with different processes suitable for products of different shapes and sizes.

Die pressing is one of the most commonly used forming methods. Pressure is applied to the powder on a press through a mold to make the powder particles closely contact and form a green body. This process is simple to operate and has high production efficiency, suitable for products with simple shapes and large batches, such as block and sheet components. The key to die pressing is to control the pressure magnitude and pressing speed. The pressure is usually between 100 – 300MPa. Too low pressure will result in low green body density and insufficient strength, while too high pressure may cause cracks; the pressing speed must be uniform to avoid uneven density in different parts of the green body.

Isostatic pressing applies equal pressure to the powder in all directions through a liquid or gas medium in a high-pressure container to form the powder into a green body. Compared with die pressing, isostatic pressing can make the green body density more uniform, especially suitable for products with complex shapes and large sizes, such as special-shaped parts and large cylinders. The pressure of isostatic pressing is generally 100 – 400MPa, the medium is mostly water or oil, and the green body after forming has low internal stress and low deformation rate during subsequent sintering.

Injection molding is suitable for producing small parts with complex shapes and high precision requirements, such as small parts in precision instruments. This process first uniformly mixes the mixed powder with a binder (such as paraffin, polymer, etc.) to make a feedstock with good fluidity, then injects the feedstock into the mold cavity through an injection machine, and after cooling, a green body containing the binder (called green part) is obtained, followed by degreasing to remove the binder to get a brown part. Injection molding can achieve near-net shape, reducing subsequent processing, but the process is complex and the cost is high.

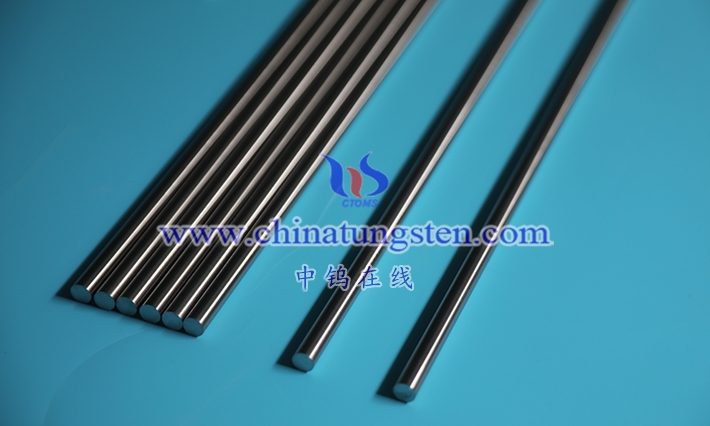

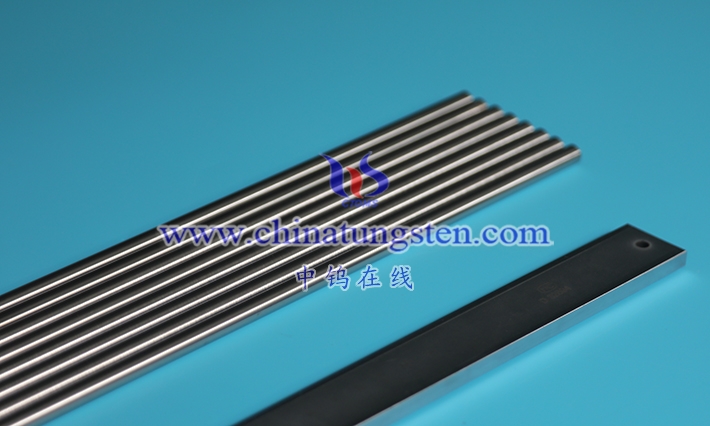

In addition, there are processes such as powder rolling and extrusion forming. Powder rolling can produce thin plates or strips, and extrusion forming is suitable for preparing rods, pipes, etc. Regardless of the forming process used, it is necessary to ensure that the green body has a certain density and strength to avoid damage during handling and sintering, and the density uniformity of the green body is crucial to the final performance of the alloy.

The WeChat public account “China Tungsten Online” updates the prices of various tungstates such as tungstates such as tungstate powder, ammonium tungstate, tungsten products, high-density tungsten alloys, cemented carbides, tungsten concentrates, etc. on a daily basis. At the same time, it provides the most professional WeChat group in the industry for everyone to exchange supply and demand information, and you can exchange information about tungsten powder at any time. Follow “China Tungsten Online” and join the China Tungsten Online WeChat exchange group. Daily tungsten product prices and supply and demand information will be delivered in a timely manner, and real-time communication will be carried out. For more tungsten product market trends, products and information, please follow the “China Tungsten Online” WeChat public account, or visit news.chinatungsten.com to obtain daily updated information.

Contact information: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595

Scan the QR code to follow the “China Tungsten Online” WeChat public account and get real-time updated tungsten, molybdenum and rare earth product market prices and information for free every morning.