The electrical conductivity and resistivity of tungsten-nickel-iron alloy are important electrical performance parameters, and they are reciprocal to each other. The higher the electrical conductivity, the lower the resistivity, and vice versa. These properties are mainly determined by factors such as the alloy’s composition, microstructure, and temperature, and have an important impact on its application in the electronic and electrical fields.

From the perspective of composition, tungsten has a relatively high resistivity (the resistivity of pure tungsten at room temperature is about 5.6 μΩ·cm), while nickel (about 6.9 μΩ·cm) and iron (about 9.7 μΩ·cm) have resistivity higher than some good conductors such as copper but lower than tungsten. In tungsten-nickel-iron alloy, tungsten, as the main component, its content is a key factor affecting the overall resistivity. Generally, with the increase of tungsten content, the resistivity of the alloy will gradually increase, usually in the range of 15 – 30 μΩ·cm, and the corresponding electrical conductivity is between 3.3×10⁷ – 6.7×10⁷ S/m. When the nickel-iron content is high, due to their relatively low resistivity, the overall resistivity of the alloy will decrease, and the electrical conductivity will increase accordingly. This characteristic of changing electrical properties through composition adjustment enables the alloy to adapt to the requirements of different scenarios for conductivity.

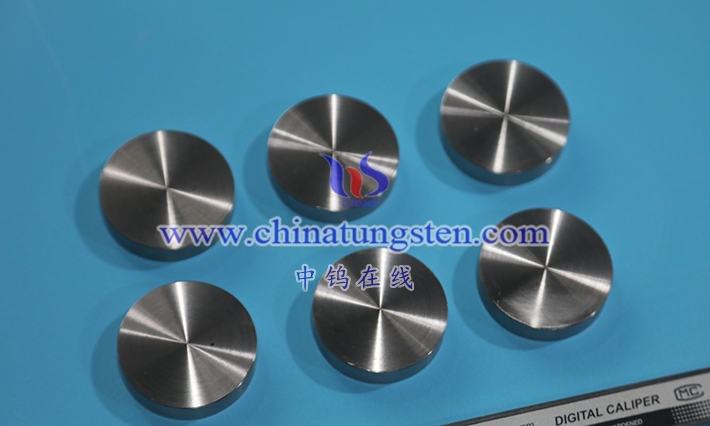

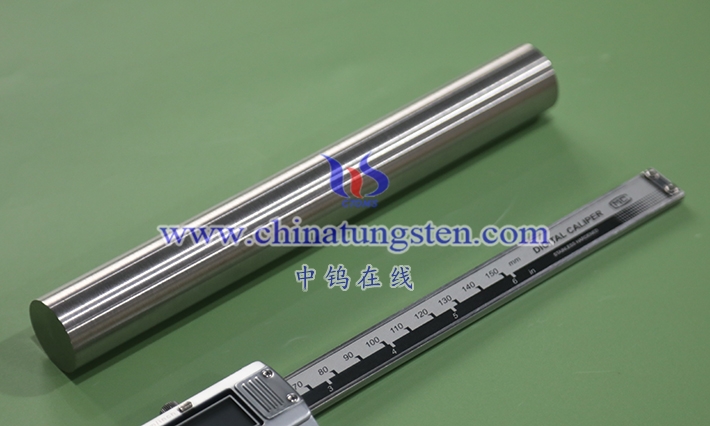

The microstructure also has a significant impact on electrical conductivity and resistivity. Alloys prepared by powder metallurgy technology, if they have high density, few internal pores, and uniform distribution of tungsten particles and nickel-iron binding phases, will have less hindrance to the transmission of electrons inside the material, resulting in higher electrical conductivity and lower resistivity. Conversely, if there are many pores, impurities or uneven distribution of tungsten particles in the alloy, it will lead to increased electron scattering, thereby reducing electrical conductivity and increasing resistivity. Therefore, optimizing the sintering process to improve the alloy’s density and structural uniformity is an effective way to improve its electrical properties.

Temperature also has a certain impact on the electrical conductivity and resistivity of tungsten-nickel-iron alloy. Similar to most metal materials, the resistivity of the alloy increases with the increase of temperature, and the electrical conductivity decreases accordingly. This is because when the temperature rises, the thermal motion of atoms intensifies, the probability of collision between electrons and atoms increases, which hinders the directional movement of electrons. In the range from room temperature to medium temperature, this change is relatively gentle, but at high temperatures, the increase in resistivity will be more obvious, which needs to be focused on when designing high-temperature electrical components.

In practical applications, the moderate electrical conductivity and resistivity of tungsten-nickel-iron alloy make it applicable in certain specific scenarios. For example, in electronic equipment, it can be used as electrode materials or lead frames, which can not only meet certain conductive requirements, but also ensure structural stability by virtue of its high density and good mechanical properties; in some components that require specific resistance values, the resistivity can be precisely controlled by adjusting the composition ratio to achieve the expected electrical functions. In addition, for electrical components working in high-temperature environments, although their electrical properties will be affected by temperature, combined with their high-temperature resistance, they can still play a role within a certain range.

The WeChat public account “China Tungsten Online” updates the prices of various tungstates such as tungstates such as tungstate powder, ammonium tungstate, tungsten products, high-density tungsten alloys, cemented carbides, tungsten concentrates, etc. on a daily basis. At the same time, it provides the most professional WeChat group in the industry for everyone to exchange supply and demand information, and you can exchange information about tungsten powder at any time. Follow “China Tungsten Online” and join the China Tungsten Online WeChat exchange group. Daily tungsten product prices and supply and demand information will be delivered in a timely manner, and real-time communication will be carried out. For more tungsten product market trends, products and information, please follow the “China Tungsten Online” WeChat public account, or visit news.chinatungsten.com to obtain daily updated information.

Contact information: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595

Scan the QR code to follow the “China Tungsten Online” WeChat public account and get real-time updated tungsten, molybdenum and rare earth product market prices and information for free every morning.