The chemical stability of tungsten-nickel-iron alloy refers to its ability to resist corrosion, oxidation and chemical reactions with other substances in different chemical environments. This property enables it to maintain structural and performance stability under complex working conditions, which is an important guarantee for its wide application. Due to the different chemical properties of each component in the alloy, its overall chemical stability is the result of the combined action of multiple factors, mainly reflected in corrosion resistance, oxidation resistance and chemical reaction characteristics with other materials.

In terms of composition, tungsten is a metal with relatively stable chemical properties. It is not easy to react with air, water and most acids and bases at room temperature. Its surface is easy to form a dense oxide film (WO₃), which can prevent the internal metal from further oxidation, providing a good basis for the chemical stability of the alloy. Nickel has excellent corrosion resistance, especially in the atmosphere, water and some non-oxidizing acids at room temperature, and the addition of nickel can enhance the alloy’s corrosion resistance to alkali solutions. The chemical stability of iron is relatively weak, and it is prone to rust in humid environments, but under the synergistic effect of tungsten and nickel, the activity of iron is inhibited, so that the overall corrosion resistance of the alloy is improved. Therefore, the chemical stability of tungsten-nickel-iron alloy benefits from the high stability of tungsten, the corrosion resistance of nickel and the synergistic effect between the three, reducing the chemical defects of a single component.

In different environments, the chemical stability of tungsten-nickel-iron alloy varies. In a dry atmospheric environment at room temperature, the alloy hardly oxidizes or corrodes, and can maintain a stable surface state for a long time; in a humid environment or atmosphere containing a small amount of salt, due to the protective effect of nickel, its corrosion rate is slow, and only slight discoloration occurs on the surface without obvious structural damage; the alloy has certain corrosion resistance in non-oxidizing acids (such as dilute sulfuric acid, hydrochloric acid), but in strong oxidizing acids (such as nitric acid), its surface oxide film will be destroyed, leading to an accelerated corrosion rate; in alkali solutions, the alloy shows good corrosion resistance due to the stability of nickel to alkali.

In addition, the chemical stability of the alloy is also related to its microstructure. Alloys with high density and few pores have better chemical stability because they have a small contact area with external corrosive media and are not easy to form corrosion cells internally; while alloys with many internal pores or impurities are prone to local corrosion, reducing overall stability. By optimizing the preparation process, increasing the alloy density and reducing impurity content, its chemical stability can be further enhanced.

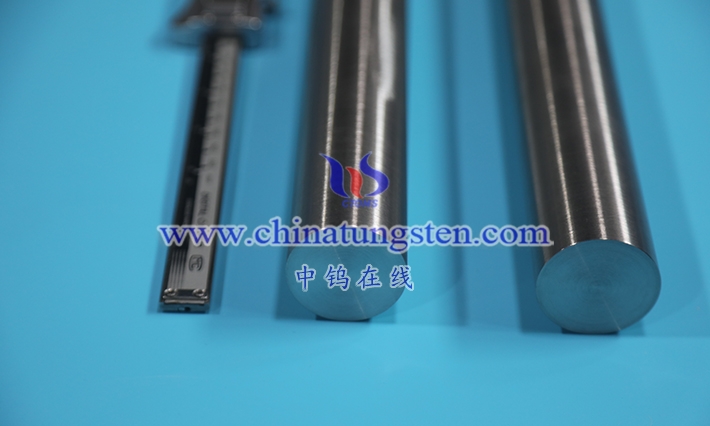

In practical applications, the chemical stability of tungsten-nickel-iron alloy makes it suitable for various complex environments. For example, in marine engineering, it can be used to manufacture counterweight components that need to resist seawater corrosion; in chemical equipment, it can be used as corrosion-resistant structural parts; in the nuclear industry, its ability to resist radiation-induced corrosion ensures the long-term stable operation of components in radiation environments. At the same time, good chemical stability also extends the service life of the alloy, reduces maintenance costs, and improves its economy and reliability in various application fields.

The WeChat public account “China Tungsten Online” updates the prices of various tungstates such as tungstates such as tungstate powder, ammonium tungstate, tungsten products, high-density tungsten alloys, cemented carbides, tungsten concentrates, etc. on a daily basis. At the same time, it provides the most professional WeChat group in the industry for everyone to exchange supply and demand information, and you can exchange information about tungsten powder at any time. Follow “China Tungsten Online” and join the China Tungsten Online WeChat exchange group. Daily tungsten product prices and supply and demand information will be delivered in a timely manner, and real-time communication will be carried out. For more tungsten product market trends, products and information, please follow the “China Tungsten Online” WeChat public account, or visit news.chinatungsten.com to obtain daily updated information.

Contact information: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595

Scan the QR code to follow the “China Tungsten Online” WeChat public account and get real-time updated tungsten, molybdenum and rare earth product market prices and information for free every morning.