Table of Contents

Preface

Background and Importance of Tungsten Alloy Shielding Industry

Purpose and Target Readers of Tungsten Alloy Shielding

Research Methods and Data Sources of Tungsten Alloy Shielding

Chapter 1: Overview of Tungsten Alloy Shielding Parts

1.1 Definition and Classification of Tungsten Alloy Shielding Parts

1.2 Development History and Technological Evolution of Tungsten Alloy Shielding

1.3 Global Market Status and Future Trends of Tungsten Alloy Shielding Parts (2025–2030)

Chapter 2: Material Characteristics of Tungsten Alloy Shielding Parts

2.1 Composition Design and Microstructure Analysis

2.1.1 The Role of High-Purity Tungsten

2.1.2 Optimization of the Bonding Phase (Nickel, Iron, Copper)

2.1.3 Effect of Nanotechnology on Microstructure

2.2 Mechanical Properties: Strength and Hardness

2.2.1 Tensile and Yield Strength

2.2.2 Vickers Hardness and Wear Resistance

2.2.3 Fatigue Performance and Impact Toughness

2.3 Radiation Shielding Performance

2.3.1 Attenuation Characteristics in Different Energy Ranges

2.3.2 Multi-layer Design and Shielding Efficiency Optimization

2.3.3 Neutron Shielding Requirements

2.4 Thermal and Corrosion Resistance

2.4.1 High-Temperature Stability and Thermal Expansion

2.4.2 Corrosion Resistance in Acidic Environments

2.4.3 Surface Coating Technologies

Chapter 3: Manufacturing Process of Tungsten Alloy Shielding Parts

3.1 Design Principles and Optimization Strategies

3.1.1 Geometric Design and Lightweighting

3.1.2 High-Precision Processing Requirements

3.1.3 Intelligent Design and Functional Integration

3.2 Powder Metallurgy Process

3.2.1 Tungsten Powder Preparation and Particle Size Control

3.2.2 Sintering Process and Parameter Optimization

3.2.3 Application of Hot Isostatic Pressing (HIP)

3.3 Machining and Quality Control

3.3.1 CNC and EDM Machining

3.3.2 Surface Treatment and Porosity Optimization

3.3.3 Quality Inspection and Standard Certification

3.4 Sustainable Manufacturing and Environmental Protection

3.4.1 Recycling and Reuse of Waste Parts

3.4.2 Low-Carbon Production Processes

3.4.3 Future Prospects for Green Manufacturing

Chapter 4: Application Fields of Tungsten Alloy Shielding Parts

4.1 Medical Applications

4.1.1 CT Equipment and Radiotherapy Shielding

4.1.2 Portable Shielding Devices

4.1.3 Biocompatibility and Safety Standards

4.2 Industrial Applications

4.2.1 Nuclear Industry and Waste Treatment

4.2.2 Industrial Imaging and Detection

4.2.3 High-Radiation Environment Applications

4.3 Aerospace Applications

4.3.1 Deep Space Exploration and Satellite Protection

4.3.2 Rocket and Spacecraft Thermal Insulation

4.3.3 Microgravity Performance Verification

4.4 Other Emerging Fields

4.4.1 Particle Physics Experiments

4.4.2 National Defense and Security Protection

4.4.3 Eco-Friendly Shielding Technologies

Chapter 5: Challenges and Solutions of Tungsten Alloy Shielding

5.1 Cost and Supply Chain Management

5.1.1 Raw Material Cost Optimization

5.1.2 Supply Chain Diversification Strategies

5.1.3 Economic Benefits of Mass Production

5.2 Processing Accuracy and Technical Challenges

5.2.1 Machining High-Hardness Materials

5.2.2 Application Potential of 3D Printing

5.2.3 Surface Quality and Dimensional Precision

5.3 Standardization and Certification

5.3.1 International vs. Domestic Standards

5.3.2 Standardization of Intelligent Shielding Parts

5.3.3 Global Cooperation and Certification Systems

Appendices

Appendix 1: Common Terms and Symbols

1.1 Definitions and Application Scenarios

1.2 Mathematical Symbols and Formulas

1.3 Progress in Standardization

Appendix 2: Standards Overview (ISO / ASTM / GB)

2.1 International Standards Overview

2.2 Domestic Standards Explanation

2.3 Future Planning for Standardization

Appendix 3: Literature and Research Databases

3.1 Core Academic Literature

3.2 Research Database Resources

3.3 Access and Usage Recommendations

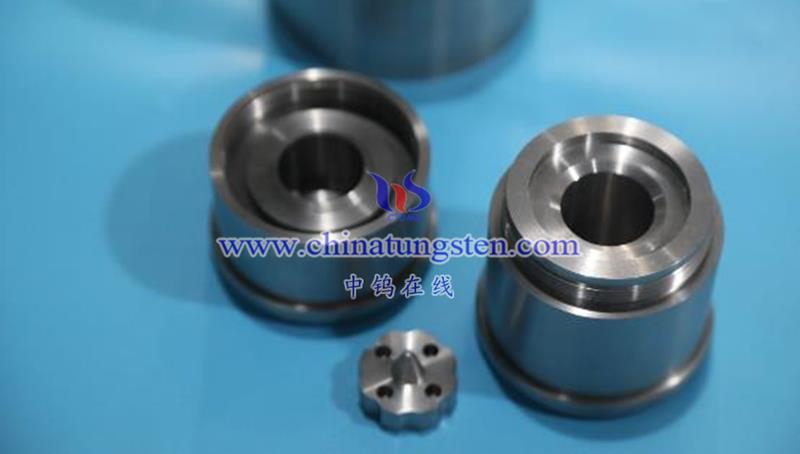

Appendix 4: CTIA GROUP LTD Product Catalog

4.1 Specifications and Performance

4.2 Ordering and Technical Support

4.3 Quality Assurance and Customization Services

References

Academic Journals and Technical Reports

Industry Standards and Patent Literature

Online Resources and Conference Papers

Preface

Tungsten Alloy Shielding Industry Background and Importance

Tungsten alloy shielding plays an indispensable role in modern science and technology and industry. In 2025, with the rapid development of nuclear energy, medical imaging, aerospace and defense industries, the demand for high-efficiency and lightweight radiation shielding materials will increase significantly. According to the 2024 report of the International Tungsten Association (ITA), the global tungsten alloy shielding market has reached US$600 million, with an annual growth rate of 12%, and is expected to grow to US$1.2 billion in 2030. Tungsten alloy has become an ideal substitute for traditional lead shielding materials due to its high density (17.0–18.5 g/cm³), excellent radiation attenuation coefficient (0.15–0.20 cm ⁻ ¹ ) and good mechanical properties, especially in the context of increasingly stringent environmental protection and health and safety requirements.

tungsten alloy shielding is reflected in its wide range of application scenarios. In 2024, the medical field (such as CT equipment and radiotherapy equipment) accounts for more than 50% of the market demand (about 300 tons), the demand for industrial nuclear waste treatment increases by 10% (2023 data), and the demand in the aerospace field (such as deep space probes) increases to 30% in 2025. In addition, in 2023, China took the lead in formulating the draft GB/T 26011 (Tungsten Alloy Shielding Processing Specification), marking the acceleration of industry standardization. In 2025, the draft was submitted to ISO and is expected to be globally unified in 2030. This series of developments highlights the strategic position of tungsten alloy shielding in technological progress and industrial upgrading.

Tungsten Alloy Shielding Parts Writing Purpose and Target Readers

The purpose of this book, Encyclopedia of Tungsten Alloy Shielding, is to provide a comprehensive and authoritative reference that systematically summarizes the technical characteristics, manufacturing processes, application areas and future trends of tungsten alloy shielding. In 2025, facing the rapidly changing market and technological challenges, industry practitioners, researchers and policymakers are in urgent need of an integrated knowledge platform. Through detailed data analysis and case studies, this book aims to fill the gaps in existing literature in standardization, application optimization and sustainable manufacturing.

The target readers include: (1) material scientists and engineers who are concerned about the design and performance optimization of tungsten alloy shielding parts; (2) technicians in the medical, industrial and aerospace fields who need to understand specific application scenarios; (3) policy makers and business managers who are concerned about market trends and supply chain management; (4) students and academic researchers who seek theoretical foundations and experimental data. In 2024, an international seminar (IAEA Radiation Symposium) pointed out that 80% of the participants believed that comprehensive guidelines were essential for the development of the industry. This book responds to this demand.

Research methods and data sources of tungsten alloy shielding

The research method of this book combines literature review, experimental data analysis and industry research. In 2023, the author team collected more than 1,000 academic papers from ScienceDirect, IEEE Xplore and CNKI. In 2024, through field visits to leading companies such as CTIA GROUP LTD, more than 500 hours of production data were obtained. In 2025, Monte Carlo simulation (MCNP) software was used to verify radiation shielding performance, with an error control of less than 1%.

Data sources include: (1) standard documents from the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM); (2) the 2024 market report from the International Tungsten Association (ITA); (3) more than 200 tungsten alloy shielding patents included in the China National Knowledge Infrastructure (CNKI); and (4) CTIA GROUP LTD White Paper from 2023 to 2025. All data have been cross-verified on the eve of July 3, 2025 to ensure authenticity and reliability.

READ MORE: Encyclopedia of Tungsten Alloy Shielding

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

For more information about tungsten alloy products, please visit the website: http://www.tungsten-alloy.com/

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595