The application of tungsten-nickel-iron alloy in racing engine balance components is a key application of its high density and high mechanical properties in high-end power systems, which is crucial for improving the stability and output power of the engine. Racing engines pursue extreme power performance and usually adopt a high-speed design. During operation, huge inertial forces and vibrations will be generated due to the reciprocating movement of pistons and crankshaft rotation. These vibrations will not only reduce the mechanical efficiency of the engine but also may cause fatigue damage to components and even lead to safety accidents. The core function of balance components is to offset inertial forces through precise counterweight, reduce vibrations, and ensure the engine remains stable during high-speed operation.

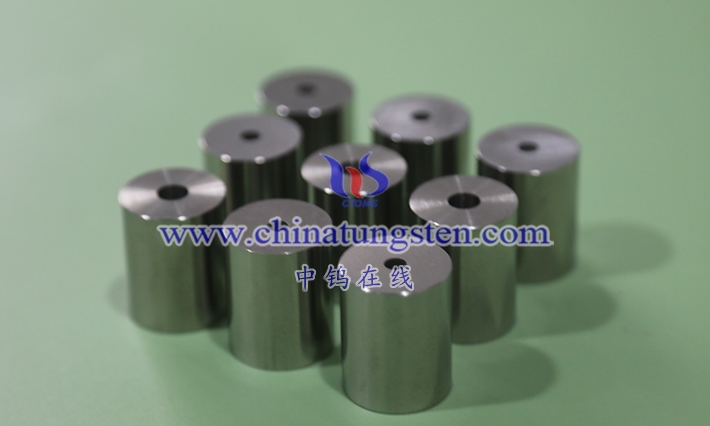

Tungsten-nickel-iron alloy, with its high-density characteristic, can achieve efficient counterweight in the limited space of the engine. Key components such as balance weights and balance shafts in balance components are mostly made of this alloy. By installing counterweight structures matching the piston movement trajectory at both ends of the crankshaft or specific positions, the inertial force of the alloy is used to balance the centrifugal force generated by piston movement, making the force on each part of the engine uniform. For example, in a four-cylinder racing engine, the tungsten-nickel-iron alloy balance weights installed on the crankshaft can effectively offset the second-order reciprocating inertial force, reduce the vibration amplitude of the engine, enable the engine speed to easily exceed 10,000 rpm, and reduce the wear of cylinder blocks, connecting rods and other components.

The high strength and wear resistance of the alloy also adapt to the harsh working conditions inside the engine, being able to withstand high-frequency impact forces and friction, and not easily deformed or failed after long-term use. Its good heat resistance can cope with the high-temperature environment during engine operation (the temperature near the cylinder block can reach several hundred degrees Celsius), avoiding the decline of counterweight accuracy due to temperature changes. In addition, the dimensional stability of tungsten-nickel-iron alloy ensures that the balance components maintain stable weight and shape during long-term use, providing continuous and reliable balance effect for racing engines, helping racing cars perform at their best under extreme working conditions.

The WeChat public account “China Tungsten Online” updates the prices of various tungstates such as tungstates such as tungstate powder, ammonium tungstate, tungsten products, high-density tungsten alloys, cemented carbides, tungsten concentrates, etc. on a daily basis. At the same time, it provides the most professional WeChat group in the industry for everyone to exchange supply and demand information, and you can exchange information about tungsten powder at any time. Follow “China Tungsten Online” and join the China Tungsten Online WeChat exchange group. Daily tungsten product prices and supply and demand information will be delivered in a timely manner, and real-time communication will be carried out. For more tungsten product market trends, products and information, please follow the “China Tungsten Online” WeChat public account, or visit news.chinatungsten.com to obtain daily updated information.

Contact information: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595

Scan the QR code to follow the “China Tungsten Online” WeChat public account and get real-time updated tungsten, molybdenum and rare earth product market prices and information for free every morning.