The application of tungsten-nickel-iron alloy in the spindle damping blocks of high-speed machine tools gives full play to its high density and high damping characteristics, which plays an important role in reducing spindle vibration and improving machining accuracy. When the spindle of a high-speed machine tool is running, especially during high-speed cutting, high-frequency vibration will be generated due to factors such as the contact between the tool and the workpiece, motor vibration, etc. These vibrations not only affect the quality of the machined surface, but also may lead to increased tool wear and shortened spindle life. The core function of the damping block is to suppress the vibration amplitude of the spindle by absorbing and consuming vibration energy.

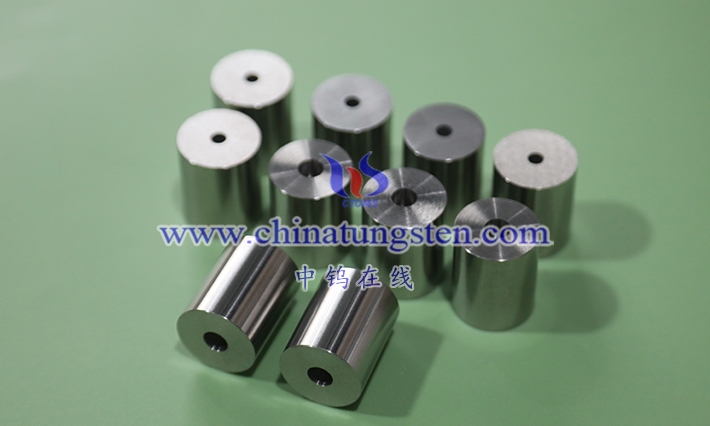

The high density of tungsten-nickel-iron alloy enables it to form a large inertial mass in a small volume. When the spindle vibrates, the damping block can generate damping force through friction or elastic deformation with the spindle, quickly attenuate the vibration energy, and make the spindle return to a stable state as soon as possible. Its uniform internal structure and good mechanical properties ensure the consistency and stability of the damping effect, without performance degradation due to long-term use.

In terms of structural design, damping blocks are usually installed at both ends of the spindle or key supporting parts, forming a rigid connection with the spindle to ensure that vibration energy can be effectively transmitted to the damping blocks and absorbed. For example, in precision turning or milling, the spindle equipped with tungsten-nickel-iron alloy damping blocks can significantly reduce radial and axial vibrations, reducing the surface roughness and improving the dimensional accuracy of machined parts. In addition, the high temperature resistance of the alloy adapts to the heat generated by the high-speed operation of the spindle, avoiding the performance degradation of the damping block due to temperature rise, ensuring that high-speed machine tools can still maintain a good vibration reduction effect during long-term continuous work.

The WeChat public account “China Tungsten Online” updates the prices of various tungstates such as tungstates such as tungstate powder, ammonium tungstate, tungsten products, high-density tungsten alloys, cemented carbides, tungsten concentrates, etc. on a daily basis. At the same time, it provides the most professional WeChat group in the industry for everyone to exchange supply and demand information, and you can exchange information about tungsten powder at any time. Follow “China Tungsten Online” and join the China Tungsten Online WeChat exchange group. Daily tungsten product prices and supply and demand information will be delivered in a timely manner, and real-time communication will be carried out. For more tungsten product market trends, products and information, please follow the “China Tungsten Online” WeChat public account, or visit news.chinatungsten.com to obtain daily updated information.

Contact information: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595

Scan the QR code to follow the “China Tungsten Online” WeChat public account and get real-time updated tungsten, molybdenum and rare earth product market prices and information for free every morning.