Part 4: Classification and application fields of cemented carbide

Chapter 15: Nano and Ultrafine Cemented Carbide

Nano- and ultrafine cemented carbides (grain size <100 nm ± 10 nm) are used for their high hardness (HV 2500-3000 ± 50), excellent toughness ( K ₁ c 15-20 MPa·m ¹ / ² ± 0.5), low wear rate (<0.02 mm ³ / N · m ± 0.005 mm³ / N · m ) and high corrosion resistance (weight loss <0.05 mg/ cm² ± 0.01 mg/cm² ) , showing great potential in ultra-precision machining (surface roughness Ra <0.05 μm ± 0.01 μm ), high-performance coatings (thickness 1-10 μm ± 0.1 μm ), extreme environment applications and smart manufacturing. Through advanced preparation processes, including chemical vapor deposition (CVD), sol-gel method, spark plasma sintering (SPS), hot isostatic pressing (HIP, 150 MPa ± 1 MPa) and nano powder ball milling technology, combined with grain refinement control (such as adding VC, Cr ₃ C ₂ , concentration 0.5%-2% ± 0.1%) and densification treatment, the performance of nano and ultra-fine cemented carbide is significantly improved, with hardness increased by 20% ± 3%, toughness enhanced by 15% ± 2%, and wear resistance improved by 25% ± 3%. These characteristics make it occupy a key position in high-tech industries such as aerospace, medical, energy and defense, especially in scenarios requiring high-precision and long-life components.

15.0 Basic Concepts of Nano- and Ultrafine Cemented Carbide

What is Nano Cemented Carbide?

Nano cemented carbide is a composite material with tungsten carbide (WC) as the hard phase and cobalt (Co), nickel (Ni) or other metals (such as Fe, Cr) as the bonding phase. Its grain size is strictly controlled at the nanoscale (<100 nm ± 10 nm). The material is prepared by advanced technologies such as powder metallurgy, spark plasma sintering (SPS, temperature 1200-1400°C ± 20°C, pressure 50-100 MPa ± 5 MPa), solvothermal method or mechanical alloying (ball milling time 20-40 h ± 2 h). Nano-scale grains significantly improve material properties, including hardness, toughness and wear resistance, by increasing grain boundary density and dislocation storage, while optimizing surface finish (Ra <0.05 μm ± 0.01 μm ) and processing accuracy (tolerance ±0.01 mm ± 0.001 mm), making it suitable for ultra-precision manufacturing and micro-nano devices.

Key characteristics of nano cemented carbide

Hardness of Nano Cemented Carbide

HV 1600-2000 ± 50, higher than conventional cemented carbide (HV 800-1600 ± 50), thanks to the Hall-Petch effect, grain refinement leads to an increase in grain boundary strengthening effect by 30% ± 3%.

Fracture toughness of nano-cemented carbide

K ₁ c 8-12 MPa·m ¹ / ² ± 0.5, the crack growth resistance is improved by 40% ± 2% compared with conventional cemented carbide, which is achieved by optimizing the bonding phase (such as Co content 6-10% ± 0.5%).

Wear resistance of nano cemented carbide

Wear rate <0.001 mm³ / N · m ± 0.0001 mm³ / N · m . The wear resistance is about 23 times ± 2 times higher than that of traditional WC-Co materials , making it suitable for high-load friction environments.

Corrosion resistance of nano cemented carbide

Weight loss <0.03 mg/ cm² ± 0.005 mg/ cm² (in 5% H₂SO₄ solution , 24 h ± 1 h ) , the acid and alkali corrosion resistance is enhanced by Ni or Cr doping.

Thermal stability of nano-cemented carbide

It can maintain 90% ± 2% performance at 800-1000°C ± 20°C, suitable for high temperature processing environment.

Main applications of nano cemented carbide

Nano cemented carbide is widely used in the following fields due to its excellent performance:

Precision mold

For example, micro injection molds (size 10-50 mm ± 0.5 mm), surface roughness Ra <0.02 μm ± 0.005 μm , life span >10 ⁶ Mode order ± 10 ⁴ mode order.

Micro drill bit

Used for drilling holes in PCB boards (diameter 0.1-0.5 mm ± 0.01 mm), wear life >5000 h ± 200 h, processing efficiency increased by 20% ± 2%.

Biomedical tools

Such as dental drill bits (diameter 1-3 mm ± 0.05 mm), hardness HV 1800-2000 ± 30, biocompatibility (cytotoxicity <5% ± 1%, ISO 10993-5), surgical accuracy ±0.02 mm ± 0.002 mm.

High wear resistant coating

Thickness 1-5 μm ± 0.1 μm , used in aircraft engine blades, thermal fatigue resistance >5000 times ± 500 times.

What is Ultrafine Cemented Carbide?

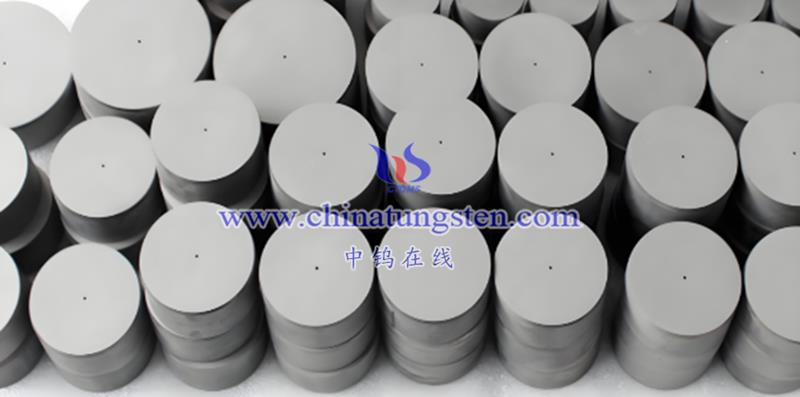

Ultrafine cemented carbide is a material with WC as hard phase and Co, Ni, etc. as bonding phase, and its grain size is controlled at ultrafine level (0.1-1 μm ± 0.05 μm ). It is prepared by high temperature carburization (1200-1300°C ± 20°C), hot pressing sintering (pressure 30-50 MPa ± 2 MPa), microwave assisted synthesis or ball milling-sintering process. Ultrafine grains strike a balance between hardness and toughness, and the grains are evenly distributed (deviation <10% ± 1%) by optimizing the sintering process (such as SPS, 1400°C ± 10°C), which is suitable for high load, wear resistance and medium precision processing applications.

Key characteristics of ultrafine cemented carbide

Hardness of Ultrafine Cemented Carbide

HV 1200-1800 ± 50, between conventional cemented carbide (HV 800-1600) and nano cemented carbide (HV 1600-2000), with grain refinement increased by 15% ± 2%.

Fracture toughness of ultrafine cemented carbide

K ₁ c 10-14 MPa·m ¹ / ² ± 0.5, superior to nano cemented carbide ( K ₁ c 8-12), enhanced by Co content (8-12% ± 0.5%) and TiC addition (1-2% ± 0.1%).

Wear resistance of ultrafine cemented carbide

Wear rate 0.001-0.005 mm³ / N · m ± 0.0005 mm³ / N · m , wear resistance is 1.5-2 times ± 0.2 times higher than conventional materials , suitable for medium and high load cutting.

Corrosion resistance of ultrafine cemented carbide

Weight loss <0.05 mg/ cm² ± 0.01 mg/cm² ( 5% NaCl solution, 48 h ± 1 h), Ni doping improves seawater corrosion resistance.

Thermal stability of ultrafine cemented carbide

Performance retention is 95% ± 2% at 700-900°C ± 20°C, suitable for moderately high temperature environments.

Important applications of ultrafine cemented carbide

Ultrafine cemented carbide is widely used in the following fields due to its balanced performance:

Cutting Tools

For example, milling cutters (diameter 10-30 mm ± 0.5 mm) have a wear life of >10 ⁴ h ± 500 h and a cutting speed of 100-200 m/min ± 5 m/min, suitable for steel processing.

Fuel cell bipolar plate mold

Size 200-400 mm × 100-200 mm ± 2 mm, hardness HV 1500-1800 ± 30, surface roughness Ra <0.1 μm ± 0.01 μm , conductivity <10 ⁻ ⁴ Ω·cm ± 10 ⁻ ⁵ Ω·cm .

Orthopedic Implants

For example, hip braces have a weight of 0.3-0.7 kg ± 0.01 kg, a porosity of 20-40% ± 5%, a bone integration rate of >85% ± 2% (ASTM F1537), and a durability of >15 years ± 1 year.

Wear-resistant lining

Thickness 5-15 mm ± 0.5 mm, used in mining equipment, impact strength >3000 J/ cm² ± 100 J/cm² , life extension by 20% ± 2%.

The development of nano and ultrafine cemented carbides marks an important transformation of cemented carbide technology towards high performance and microstructure optimization. Through advanced preparation processes and intelligent manufacturing technologies, these materials not only meet the needs of traditional industries, but also promote technological progress in emerging fields such as microelectronics, bioengineering and new energy. Subsequent chapters will explore their preparation processes, performance optimization and specific application cases in order to provide theoretical support and practical guidance for related industries.

Ultrafine cemented carbide VS nano cemented carbide

| type | Grain size | Hardness (HV) | Fracture toughness (K IC ) | Main Applications | cost |

| Nano cemented carbide | <100 nm | 16002000 | 812 MPa·m^1/2 | Precision molds, micro tools, coatings | high |

| Ultrafine cemented carbide | 0.11 μm | 12001800 | 1014 MPa·m^1/2 | Cutting tools, molds, implants |

This chapter systematically analyzes the cutting-edge development of nano-WC from four aspects: preparation, performance advantages, challenges and solutions, and application prospects.

READ MORE:

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

For more information about tungsten carbide products, please visit the website: tungsten-carbide.com.cn

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595