The differences between TIG welding and MIG welding are as follows:

The welding principle is different

TIG welding (Tungsten Inert Gas Welding) uses a non-melting tungsten electrode to generate an electric arc, using an inert gas such as argon to protect the weld area, and the welder can add filler metal manually or automatically as needed. MIG welding (Metal Inert Gas Welding) uses a molten metal electrode that can be continuously fed as a welding wire, and an arc is formed between the electrode and the workpiece, and the filler metal is automatically fed into the melt pool.

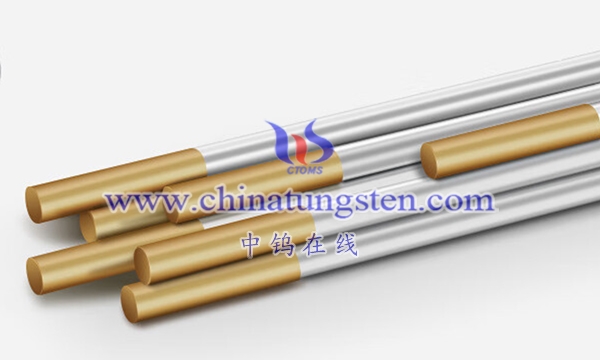

Electrode types are different

TIG welding uses tungsten electrodes, which are not consumed; MIG welding uses metal welding wire, which will be melted and consumed during welding.

Welding speed and efficiency

MIG welding has a fast welding speed, which is suitable for mass production and thick plate welding; TIG welding is slower but provides higher quality welds suitable for thin sheet and precision welding.

Weld quality and appearance

TIG welds are of high quality and beautiful welds, suitable for demanding welding tasks; Although MIG welding has better welds, there is more weld spatter, and the weld surface needs to be treated later.

The fields of application are different

TIG welding is widely used in aerospace, medical equipment, precision instruments and other fields with high requirements for weld quality; MIG welding is mostly used for large-scale welding in industries such as automobile manufacturing, construction, and shipbuilding.

Ease of operation

TIG welding operation technology requirements are high, requiring skilled welders to control the current and fill the wire; MIG welding is relatively simple and suitable for beginners and automated production.

More details of tungsten electrodes, please visit website: http://tungsten.com.cn/tungsten-electrodes.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595