Argon arc welding has high requirements for power supply equipment, which is directly related to welding quality and operational stability. It mainly includes the following aspects:

Current stability

The welding power supply must be able to provide a stable output current to avoid arc instability caused by current fluctuations. The stable current helps keep the arc continuous and uniform, guaranteeing the quality of the weld.

Wide current regulation range

Argon arc welding is suitable for a wide range of materials and thicknesses, as well as a wide range of currents required. The power supply should have precise adjustment capabilities from low current (tens of amps) to high current (several hundred amps) to meet the needs of different welding processes.

Multiple arc starting methods are supported

Including high-frequency arcing, contact arcing, boost arcing, etc., it can adapt to different welding scenarios and welding equipment. High-frequency arcing is particularly commonly used to ignite arcs without contact and reduce electrode pollution.

AC/DC switching capability

The power supply should be able to support both alternating current (AC) and direct current (DC) outputs. AC is suitable for welding alloys such as aluminum and magnesium, and DC is suitable for welding stainless steel, carbon steel and other materials, meeting the welding needs of various materials.

Pulse function

Modern argon arc welding power supplies are often equipped with pulse welding functions, which can control the periodic change of current to achieve heat input control, weld morphology optimization and deformation reduction, and are suitable for thin plate and precision welding.

The protection function is perfect

It has safety measures such as overheat protection, overcurrent protection, and short circuit protection to ensure the safety of equipment and operators and extend the service life of the equipment.

Good HMI

The intuitive control panel and display make it easy for welders to set parameters and monitor welding status, improving operational efficiency and accuracy.

Adaptable

It is suitable for different environmental conditions (such as on-site and workshop), and has good anti-interference ability and stability.

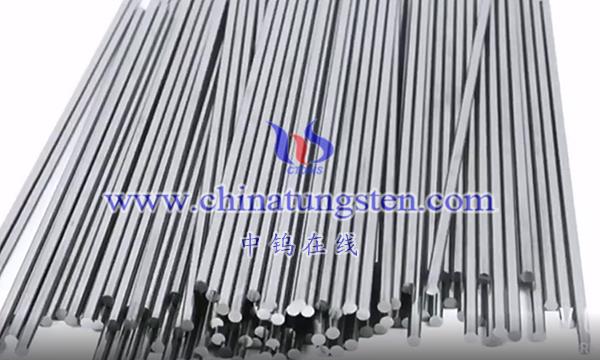

More details of tungsten electrodes, please visit website: http://tungsten.com.cn/tungsten-electrodes.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595