The main reasons for tungsten electrode deformation are as follows:

Excessive Soldering Temperature

Tungsten electrodes are subjected to high temperatures during the welding process, and if the current is too high or the arc is unstable, the temperature of the electrode head will rise sharply, resulting in softening or even partial melting of the tungsten material, resulting in deformation.

Unreasonable Sharpening Angle

If the sharpening angle is too blunt or uneven, the heat distribution of the electrode tip will be uneven, forming a local high-temperature area, resulting in aggravated deformation and ablation.

Insufficient Or Incorrect Direction Of Shielding Gas Flow

The flow rate of the shielding gas is too small or the airflow is unstable, which cannot effectively isolate the air, resulting in aggravated oxidation of the electrode head, abnormal heat conduction, and then deformation.

Mechanical Impact Or Collision

Mechanical impacts on electrodes during installation, transportation, or operation can cause them to bend, break, or deform the ends.

Welding Equipment Failure

If the current fluctuates violently, the welding power supply is unstable, or the high-frequency arcing equipment is abnormal, it will cause the electrode to withstand uneven heat load, causing deformation.

Electrode Quality Issues

The electrode material is not pure enough or has impurities and defects inside, and it is also easy to deform at high temperatures.

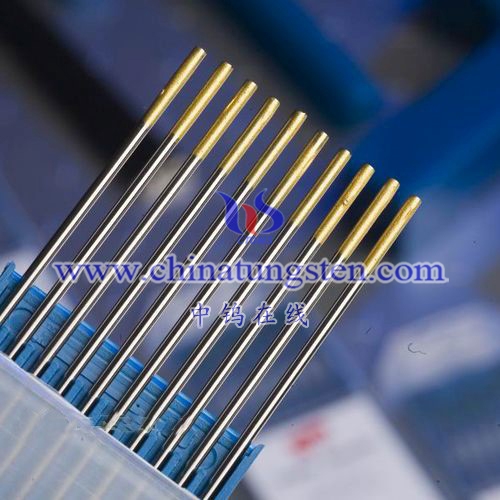

More details of tungsten electrodes, please visit website: http://tungsten.com.cn/tungsten-electrodes.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595