The position of the tungsten electrode does affect arc stability in TIG welding. The stability of the arc is directly related to whether the welding process is smooth and whether the weld is well formed, and the position of the tungsten electrode is an important factor affecting the stability of the arc.

First, the distance between the tungsten electrode and the workpiece needs to be controlled within a reasonable range. It is generally recommended to maintain a clearance of 1.5 to 3 mm. If the distance is too close, the electrode is easy to contact the melt pool, resulting in a short circuit or sticking; If the distance is too far, the arc will become divergent, the heat concentration will decrease, the weld penetration depth is insufficient, and arcing will become difficult.

Secondly, the orientation of the electrode also affects the concentration of the arc. If the electrode is tilted at an improper angle, such as too vertical or too deflected, it will offset the arc, disrupting the thermal concentration on the weld pool, and ultimately affecting the weld shape and weld quality.

Additionally, if the electrode deviates from the weld centerline, the arc will deflect to one side, resulting in weld asymmetry, uneven penetration depth, and even defects such as porosity or slag inclusion.

In practice, the welder also needs to keep the welding torch stable. If the electrode shakes violently during movement, it will cause the arc to fluctuate between length and shortness, uneven weld waveform, and reduce the weld quality.

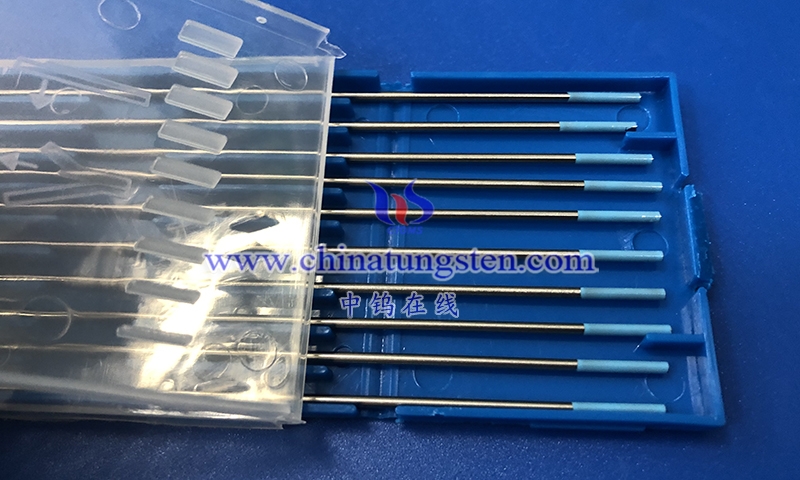

More details of tungsten electrodes, please visit website: http://tungsten.com.cn/tungsten-electrodes.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595