The impact of poor gas protection on argon arc welding tungsten electrodes is mainly reflected in the following aspects:

Oxidation And Ablation Of The Electrodes Intensifies

When the protective gas is insufficient or contains impurities, the electrode is easy to contact with oxygen in the air and undergo oxidation reactions, resulting in ablation and corrosion on the surface of the tungsten electrode, and the electrode life is significantly shortened.

The Arc Is Unstable

Poor gas protection will pollute the arc environment, and it is difficult to maintain stability in the arc, which is manifested as arc runout and arc extinguishing frequently, affecting the welding quality and operational stability.

Tungsten Inclusions And Welding Defects

Insufficient shielding gas leads to oxidation in the welding area, which is more likely to produce tungsten inclusions, porosity, cracks and other defects in the weld, reducing the mechanical properties and reliability of the weld.

The Electrode Tip Is Abnormally Shaped

When the gas protection is insufficient, the electrode is prone to poor spheroidization, tip melting or fracture, which affects the arc initiation performance and arc concentration of the electrode.

Contamination Of The Welding Area

Insufficient shielding gas cannot effectively isolate nitrogen and moisture in the air, leading to weld pool contamination and affecting weld forming and material properties.

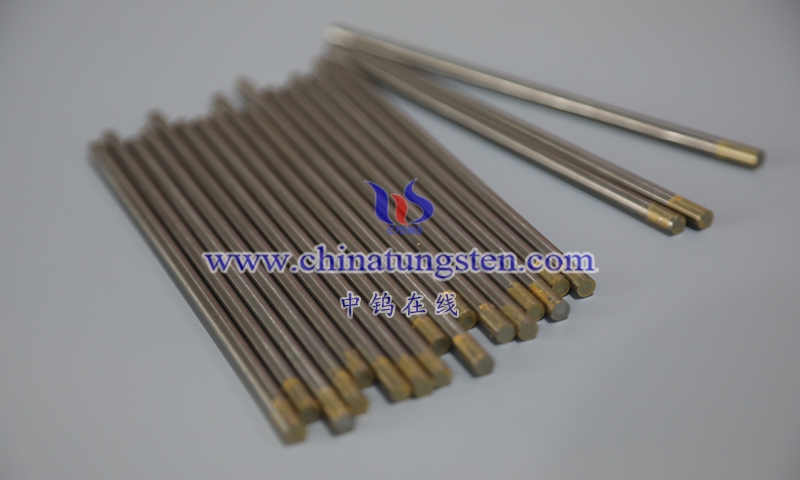

More details of tungsten electrodes, please visit website: http://tungsten.com.cn/tungsten-electrodes.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595