The deviation of the tungsten electrode from the center has a significant impact on the quality of the weld, mainly reflected in the following aspects:

The Arc Is Offset, And The Weld Is Formed Unevenly

If the tungsten electrode is not in the center of the torch, the arc will be biased to one side, resulting in uneven weld heat input, inconsistent weld width and depth, and reduced weld appearance and dimensional accuracy.

Welding Pool Control Is Difficult

The deviation of the electrode from the center causes the arc concentration point to shift, the welding pool is heated unevenly, and the shape of the weld pool is unstable, which can easily cause welding defects, such as porosity, cracks or non-penetration.

Electrode Loss Increases

The eccentric electrode causes the arc to be concentrated on one side of the electrode, which overheats locally, and the electrode head is easy to ablate and wear faster, reducing the electrode life.

The Arc Is Unstable

The offset of the electrode position affects the reliability of high-frequency arc initiation or contact arcing, which may lead to difficulty in arcing or arc runout, increasing the difficulty of welding operations.

Incomplete Coverage Of Protective Gas

Deviation from the center can lead to uneven flow of shielding gases, inadequate protection in some weld areas or electrodes, and increased risk of oxidation and contamination.

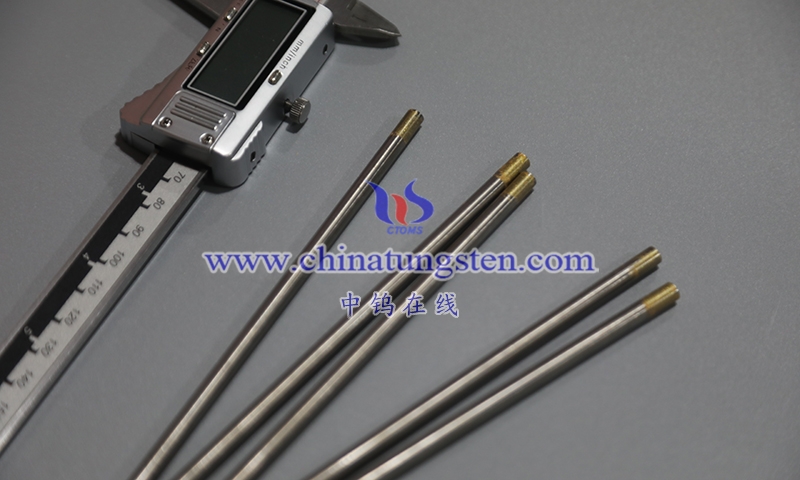

More details of tungsten electrodes, please visit website: http://tungsten.com.cn/tungsten-electrodes.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595